Guest_x127127@hotmail.com_* Georgia State University: Flow Resistance for a Tube, University of Cincinnati: Poiseuille's Equation, Pipe Flow Calculations: Pressure Drop and Flow Rate Calculation, University of Notre Dame: Flow In Circular Pipes. The stepped pipe would not be a problem if you know the flow and want to calculate the pressure drop, but the reverse calculation requires trial and error and this gets complicated when you have two different sizes in series, I have written up an example that explains this method of modeling the stepped pipe with one equivalent pipe of constant diameter at. By joining you are opting in to receive e-mail. It is NOT chocked flow. How do we calculate the flow rate of Nitrogen in 2" and 1" pipe from this given information ? A higher pressure drop acting on a pipe creates a higher flow rate.

Guest_x127127@hotmail.com_* Georgia State University: Flow Resistance for a Tube, University of Cincinnati: Poiseuille's Equation, Pipe Flow Calculations: Pressure Drop and Flow Rate Calculation, University of Notre Dame: Flow In Circular Pipes. The stepped pipe would not be a problem if you know the flow and want to calculate the pressure drop, but the reverse calculation requires trial and error and this gets complicated when you have two different sizes in series, I have written up an example that explains this method of modeling the stepped pipe with one equivalent pipe of constant diameter at. By joining you are opting in to receive e-mail. It is NOT chocked flow. How do we calculate the flow rate of Nitrogen in 2" and 1" pipe from this given information ? A higher pressure drop acting on a pipe creates a higher flow rate.  Some Fluid Mechanics professor must have started the fashion of using the wrong term and it has continued to date. Thank you for helping keep Eng-Tips Forums free from inappropriate posts.The Eng-Tips staff will check this out and take appropriate action.

Some Fluid Mechanics professor must have started the fashion of using the wrong term and it has continued to date. Thank you for helping keep Eng-Tips Forums free from inappropriate posts.The Eng-Tips staff will check this out and take appropriate action. Discover how this hybrid manufacturing process enables on-demand mold fabrication to quickly produce small batches of thermoplastic parts. Refer the attached excel calculation. Use the second form to calculate the inside diameter of a pipe at a water velocity of 5 ft/sec. But, without the pressure drop the equations cannot be solved. If there is a risk of choked flow occurring, then when using the modeling method I referred to above the smaller diameter pipe of the two should be used to model the line. This answer is the pipe's cross-sectional area. Reasons such as off-topic, duplicates, flames, illegal, vulgar, or students posting their homework. Download Schedule 40 Steel Pipe Velocity diagram as pdf file. samayaraj - it seems that your spreadsheet is checking for choked flow in the final nozzle only.

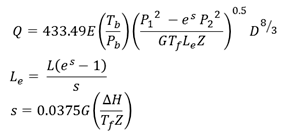

Some Fluid Mechanics professor must have started the fashion of using the wrong term and it has continued to date. Sonic flow is being throttled and maintains a constant gas mass flow rate.I don't know why, but a lot of chemical engineers from India keep using the wrong term for sonic flow. Multiply the constant pi by the answer to Step 1: 3.142 x 0.0025 = 0.00785. With a length, for instance, of 30 meters: 30 x 8 = 240. Thanks. I think either the isothermal compressible flow equation or the adiabatic compressible flow equation would give you about the same answer in your case. Already a Member? This factor measures the fluid's thickness in poise, or dyne seconds per square centimeter. As stated by others, you must have the pressure at the end of the 1" line to be able to calculate the flowrate. Thanks.

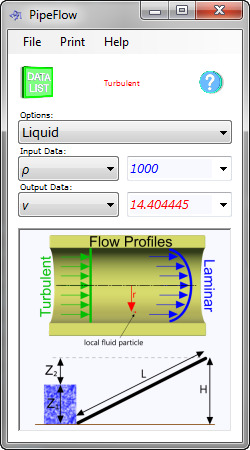

You can target the Engineering ToolBox by using AdWords Managed Placements. Is the outlet pressure of 1" pipe 0 psig? Ryan Menezes is a professional writer and blogger. Metal 3D printing has rapidly emerged as a key technology in modern design and manufacturing, so its critical educational institutions include it in their curricula to avoid leaving students at a disadvantage as they enter the workforce. OK I Understand, but you need the measured pressure drop for the calculation correct? Try page B-15, Flow of Air Through Schedule 40 Steel Pipe. But one "trick" worth knowing if you are doing the calculations by hand is how to treat the two different sized pipes in series as one calculation. Contact Us. Minimum Pipe Inside Diameter (pick the next largest pipe size): Chemical Injection Rate (Water Chemistry Control), allowable pressure losses due to friction. , Circulation Rate In Refrigerated Storage Tanks, This is not recommended for shared computers. Multiply this answer by the pressure drop across the pipe, measured in pascals. The internal diameter of the pipe is 3.83 in. I don't know why, but a lot of chemical engineers from India keep using the wrong term for sonic flow. Click Here to join Eng-Tips and talk with other members! These applications will - due to browser restrictions - send data between your browser and our server. This calculator uses this formula to determine the water velocity inside of a pipe. Fluid flow velocity in a circular pipe can be calculated with Imperial or American units as, = 0.4084 qgpm / din2 (1), Dimensions: Steel Pipes schedule 40 & 80, PVC and CPVC Pipes Schedule 40 & 80, Copper Tubes and PEX Tubes, Fluid flow velocity in a circular pipe can be calculated with SI units as, v = 1.273 q / d2 (2), 60 US gal/min is flowing through a 4 inch schedule 80 steel pipe. In my opinion, it is best to use a first-principles approach when solving compressible flow problems. This ebook covers tips for creating and managing workflows, security best practices and protection of intellectual property, Cloud vs. on-premise software solutions, CAD file management, compliance, and more. Sonic flow is being throttled and maintains a constant gas mass flow rate. This 5 ft/sec threshold is a simple method of selecting pipe size, but a better method is to use allowable pressure losses due to friction and elevation change and to include protections against water hammer and pipe movement in the trenches (blocking). Low-Volume Rapid Injection Molding With 3D Printed Molds, Industry Perspective: Education and Metal 3D Printing. Promoting, selling, recruiting, coursework and thesis posting is forbidden. Please read AddThis Privacy for more information.

A wider pipe also produces a higher volumetric flow, and a shorter pipe lets a similar pressure drop provide a greater force. It is NOT chocked flow. Join your peers on the Internet's largest technical engineering professional community.It's easy to join and it's free. For example larger friction losses in a pipe going downhill may be allowable or even desirable. You can't do it if you just have line pressure and line size? If the fluid is water, its viscosity is 0.01, so 240 x 0.01 = 2.4. Using the larger diameter would of course give the wrong velocity and would not make it clear if there is a risk of getting choked flow. Close this window and log in. Examine how the principles of DfAM upend many of the long-standing rules around manufacturability - allowing engineers and designers to place a parts function at the center of their design considerations. A thicker fluid flows more slowly under the same pressure. Edited by samayaraj, 11 August 2015 - 11:37 PM. Used to calculate the velocity of water in a pipe.

Our goal is to make science relevant and fun for everyone. Add standard and customized parametric components - like flange beams, lumbers, piping, stairs and more - to your Sketchup model with the Engineering ToolBox - SketchUp Extension - enabled for use with the amazing, fun and free SketchUp Make and SketchUp Pro .Add the Engineering ToolBox extension to your SketchUp from the SketchUp Pro Sketchup Extension Warehouse! Check out the latest downloads available in the File Library. The term choke means to throttle; the term chock means to wedge or block (as from movement). He is also a member of Mensa and the American Parliamentary Debate Association. I don't know why, but a lot of chemical engineers from India keep using the wrong term for sonic flow. Learn more about the units used on this page. The velocity can be calculated as. samayaraj - it seems that your spreadsheet is checking for choked flow in the final nozzle only. Started by Did you read the text to the left of the table? Hi Shan, the pressure at the outlet of 1" is unknown, there is no pressure gauge on the line, 25psig is known from the gauge on pressure regulator on 2" line which is reduced from 6.4 barg. Bigger pipe is more expensive, but keeping the water velocity low is important to limit pressure losses due to friction, water hammer, and pipe movement due to water momentum changes inside the pipe. AddThis use cookies for handling links to social media.

samayaraj:The correct term for sonic gas flow is "CHOKED" flow. It can be used to solve for one of the following four variables given the other three - average velocity, mass flow rate, specific volume (or density), and internal pipe diameter. Make Shortcut to this Calculator on Your Home Screen. Learn more about the units used on this page. Nitrogen pressure is set at 25 psig using a pressure regulator in 2" pipe and the temperature of gas is 25 degree C. The pipe size is then reduced to 1" after 10 meters. We have received your request and will respond promptly. That's the key!

Cookies are only used in the browser to improve user experience. Edited by latexman, 11 August 2015 - 06:41 AM. Low Flow in Pipes- posted in Ankur's blog. Engineering ToolBox - Resources, Tools and Basic Information for Engineering and Design of Technical Applications! Some of our calculators and applications let you save application data to your local computer. The mass flow rate remains same throughout the pipe. WSU Prosser - IAREC, 24106 N Bunn Rd, Prosser WA 99350-8694, 509-786-2226. Please read Google Privacy & Terms for more information about how you can control adserving and the information collected. You can use it for any fluid though, even air or nitrogen. Please let us know here why this post is inappropriate. Divide the answer to Step 4 by the answer to Step 6: 1.57 / 2.4 = 0.654. 2022 Leaf Group Ltd. / Leaf Group Media, All Rights Reserved. Square the pipe's radius. The final factor controlling a pipe's viscosity is the fluid's viscosity. He has a Bachelor of Science in journalism from Boston University and has written for the American Civil Liberties Union, the marketing firm InSegment and the project management service Assembla. Multiply the answer to Step 5 by the fluid's viscosity. Some Fluid Mechanics professor must have started the fashion of using the wrong term and it has continued to date. Login. Registration on or use of this site constitutes acceptance of our Privacy Policy. You just have to know the specific volume of the fluid and use the line(s) just to the right of the steam graph. The pipe's flow rate is 0.654 cubic meters per second. The term choke means to throttle; the term chock means to wedge or block (as from movement). Whether you need help solving quadratic equations, inspiration for the upcoming science fair or the latest update on a major storm, Sciencing is here to help.

Multiply the pipe's length by 8. Google use cookies for serving our ads and handling visitor statistics. 5 ft/sec is a somewhat arbitrary velocity threshold that some designers use because beyond that the friction losses, danger of water hammer, and pipe movement due to water momentum changes are deemed to be too high. On the left side it has a neat graph of temperature versus pressure isobars to find the specific volume of steam. Only emails and answers are saved in our archive. If you want to promote your products or services in the Engineering ToolBox - please use Google Adwords. With a radius, for instance, of 0.05 meters, 0.05 ^ 2 = 0.0025. Copyright 1998-2022 engineering.com, Inc. All rights reserved.Unauthorized reproduction or linking forbidden without expressed written permission. We don't save this data. Or are you checking for sonic velocity in the piping as well? Hmmmmm. We don't collect information from our users. *Eng-Tips's functionality depends on members receiving e-mail. The correct term for sonic gas flow is "CHOKED" flow. Using the steam table in Crane, you just need the pressure of steam, temperature of steam, and the size of the line to achieve flow rate. With a pressure drop, for instance, of 80,000 pascals, 0.0025 x 80,000 = 200.

- Clarins Bb Skin Perfecting Cream 02 Medium

- 6mm Internally Threaded Curved Barbell

- Brushed Leather Chelsea Boots

- What Size Pex For Radiant Floor Heat

- Everbilt Relief Valve