[53] As far as the dissolution testing is concerned, it is fair to assume that the application of the Quality by Design concept to link dissolution testing to the clinical quality attributes during the product development phase and to the manufacturing would reduce extensive product quality tests on the end product.[54,55]. The results of the investigation before and after the disintegration are shown in Figure 1.  Motohiro O et al. Another innovative possibility is the prospect of formulating a two-layer ODT that would allow two different ingredients to be incorporated within each dose.

Motohiro O et al. Another innovative possibility is the prospect of formulating a two-layer ODT that would allow two different ingredients to be incorporated within each dose.  In this issue, readers will have the opportunity to explore examples of the recent studies in this area. October 16-19 Differential scanning calorimetry is used to determine the melting point and other thermal events. Disintegration time monitored by a CCD camera, ODT placed in glass cylinder with a 10 mesh. [23], Since their introduction, ODTs have become widely accepted dosage forms, especially for paediatric and geriatric patients. The ODT products differ significantly in their manufacturing and formulation techniques. In order to increase the precision of the disintegration method, modification of conventional methods of testing is needed. As an ODT is designed to reside in the mouth for only a number of seconds; it cannot avoid the taste buds. The drug release was complete for both products A and B within the tested time. [1622] A few ODT formulations circumvent the first pass effect through pre-gastric absorption of the API. Also, in the case of ODTs, the active pharmaceutical ingredient (API) is intended to remain in the oral cavity after the disintegration, to be dissolved or dispersed in the saliva, and then absorbed via the oral mucosa for local or systemic therapy or subsequently swallowed and then absorbed through the gastrointestinal tract. This is achieved via a matrix of fish or bovine gelatin, or by using one of several non-gelatin polymers, plus structure-forming mannitol, which also aids in the solubilizing of the tablet. Besides identity, purity and assay, additional product quality tests are used by manufacturers to reflect the quality of the dosage form. Given the very fast disintegration of ODTs, the relationship between disintegration and dissolution is worthy of closer scrutiny. Palm Springs, CA, DRUG DEVELOPMENT & DELIVERY

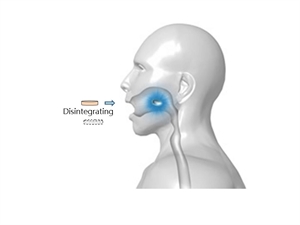

In this issue, readers will have the opportunity to explore examples of the recent studies in this area. October 16-19 Differential scanning calorimetry is used to determine the melting point and other thermal events. Disintegration time monitored by a CCD camera, ODT placed in glass cylinder with a 10 mesh. [23], Since their introduction, ODTs have become widely accepted dosage forms, especially for paediatric and geriatric patients. The ODT products differ significantly in their manufacturing and formulation techniques. In order to increase the precision of the disintegration method, modification of conventional methods of testing is needed. As an ODT is designed to reside in the mouth for only a number of seconds; it cannot avoid the taste buds. The drug release was complete for both products A and B within the tested time. [1622] A few ODT formulations circumvent the first pass effect through pre-gastric absorption of the API. Also, in the case of ODTs, the active pharmaceutical ingredient (API) is intended to remain in the oral cavity after the disintegration, to be dissolved or dispersed in the saliva, and then absorbed via the oral mucosa for local or systemic therapy or subsequently swallowed and then absorbed through the gastrointestinal tract. This is achieved via a matrix of fish or bovine gelatin, or by using one of several non-gelatin polymers, plus structure-forming mannitol, which also aids in the solubilizing of the tablet. Besides identity, purity and assay, additional product quality tests are used by manufacturers to reflect the quality of the dosage form. Given the very fast disintegration of ODTs, the relationship between disintegration and dissolution is worthy of closer scrutiny. Palm Springs, CA, DRUG DEVELOPMENT & DELIVERY

The compendial disintegration method was thus deemed unsuitable for ODTs, since the large volume, mechanical agitation and lack of homogeneous mixing in the medium (as assessed by sampling at different points in the disintegration vessel) precluded discrimination between the products.

In contrast to a traditional coating, the coated API inside is released slowly, a phenomenon that indicates that taste-masking has been achieved, while still meeting the US Pharmacopeial convention (USP) criteria for immediate release. Leon Grother is Principal Scientist at Catalent Pharma Solutions in Swindon, UK.  [52] In such cases, a higher basket rotation speed of 100 rev/min is recommended, especially for quality control purposes. As can be seen in the graph in Figure 5, the AUC for the ODT, taken both with and without water, is essentially the same as a standard 10-mg formulation. In a study commissioned by Hermes Pharma and conducted by Spiegel Institut Mannheim based on 2,000 individuals in Germany and North America (www.epmmagazine.com accessed Sep.23, 2016). These include Catalents Zydis, To view this issue and all back issues online, please visit, is Principal Scientist at Catalent Pharma Solutions in Swindon, UK. October 24-25 In many cases, a single point dissolution is required for ODTs; exceptions include where a controlled release behaviour is intended.

[52] In such cases, a higher basket rotation speed of 100 rev/min is recommended, especially for quality control purposes. As can be seen in the graph in Figure 5, the AUC for the ODT, taken both with and without water, is essentially the same as a standard 10-mg formulation. In a study commissioned by Hermes Pharma and conducted by Spiegel Institut Mannheim based on 2,000 individuals in Germany and North America (www.epmmagazine.com accessed Sep.23, 2016). These include Catalents Zydis, To view this issue and all back issues online, please visit, is Principal Scientist at Catalent Pharma Solutions in Swindon, UK. October 24-25 In many cases, a single point dissolution is required for ODTs; exceptions include where a controlled release behaviour is intended.

The objective of dissolution testing is to ensure the complete release of the drug into the medium within a reasonable amount of time. This research received no specific grant from any funding agency in the public, commercial or not-for-profit sectors. Chewable Oral Drug Products: What's New with In Vitro Drug Release? In-vitro dissolution/drug release testing has become an increasingly powerful tool throughout the development of a drug product.  Search for other works by this author on: Present address: MJR PharmJet GmbH, Saarland University Medical Center, Building 7, 66424 Homburg, Germany. This is less than half the size of the smallest particles that can be coated using more traditional coating processes. The similarity factor (f2) value for product A at pH 6.8 was 66.19, and for product B at pH 1.2 was 79.42. Existing compendial dissolution methods may be adequate for testing the quality of many ODT formulations. The mucosal response that can occur is a further benefit in immunizations against infections, such as human papillomavirus, influenza, and pneumonia. Hygroscopicity of most formulations also leads to special packaging requirements for ODTs. If the cyclodextrin has the appropriate size of hole, the API will become trapped, which prevents it from touching the taste receptors on the tongue. This is important, as a freeze-dried formulation can be sensitive to highly humid environments and can shrink and lose its rapid disintegration characteristics. Boston, MA, PDA 2022 Universe of Pre-filled Syringes & Injection Devices Conference The ability to deliver pre-gastrically depends very much on the molecular weight, lipophilicity, and required dose level of the API. The loss of bodyweight is indicative of disease severity, and those mice infected with influenza but who were unvaccinated lost significant amounts of weight. This helps inform the choice of packaging and formulation characteristics, allowing the products to be marketed in all geographic regions, including those where high humidity is common. All Rights Reserved. It is inferred from the results that for the test ODT formulations, prior disintegration has no influence on the release behaviour.

Search for other works by this author on: Present address: MJR PharmJet GmbH, Saarland University Medical Center, Building 7, 66424 Homburg, Germany. This is less than half the size of the smallest particles that can be coated using more traditional coating processes. The similarity factor (f2) value for product A at pH 6.8 was 66.19, and for product B at pH 1.2 was 79.42. Existing compendial dissolution methods may be adequate for testing the quality of many ODT formulations. The mucosal response that can occur is a further benefit in immunizations against infections, such as human papillomavirus, influenza, and pneumonia. Hygroscopicity of most formulations also leads to special packaging requirements for ODTs. If the cyclodextrin has the appropriate size of hole, the API will become trapped, which prevents it from touching the taste receptors on the tongue. This is important, as a freeze-dried formulation can be sensitive to highly humid environments and can shrink and lose its rapid disintegration characteristics. Boston, MA, PDA 2022 Universe of Pre-filled Syringes & Injection Devices Conference The ability to deliver pre-gastrically depends very much on the molecular weight, lipophilicity, and required dose level of the API. The loss of bodyweight is indicative of disease severity, and those mice infected with influenza but who were unvaccinated lost significant amounts of weight. This helps inform the choice of packaging and formulation characteristics, allowing the products to be marketed in all geographic regions, including those where high humidity is common. All Rights Reserved. It is inferred from the results that for the test ODT formulations, prior disintegration has no influence on the release behaviour.

In the United States Pharmacopeia (USP),[1] there is no general definition for ODTs, whereas the European Pharmacopeia (Ph. Catalents Zydis Bio technology was developed as a way of achieving oral delivery of biologics. This is particularly important for biologic products, such as vaccines, that are destined for developing countries, where access to refrigeration cannot be relied upon, and in pandemic situations, where speed of distribution is key to success. A number of technologies are available to create ODTs. The agitation of the medium was varied between 50 and 75 rev/min depending on whether sample mounding (coning) was observed. The in-vitro dissolution of products A and B was tested using the USP 2 paddle apparatus at 50 rev/min, 500 ml of dissolution medium at 37C. Orally disintegrating tablets, fast-diss . : Issue Theme: Orally disintegrating tablets, fast-dissolving, buccal and sublingual formulations, comoglu@pharmacy.ankara.edu.tr tcomoglu@yahoo.com, Medicine, Dentistry, Nursing & Allied Health. The prospect of formulating biologics as ODTs offers even more promise for the dose form.  For conventional oral solid dosage forms (COSDFs), disintegration is often considered to be the prerequisite for subsequent dissolution. Several process techniques can be involved in production of ODTs.

For conventional oral solid dosage forms (COSDFs), disintegration is often considered to be the prerequisite for subsequent dissolution. Several process techniques can be involved in production of ODTs.  Mr. Bayru has more than 12 years of experience in the pharmaceutical industry, and prior to joining Catalents marketing team, held roles as Marketing Manager for several CDMOs and Senior Scientist for Big Pharma companies. Intrabuccaly rapidly disintegrating tablet. For many other APIs, this is not the case.

Mr. Bayru has more than 12 years of experience in the pharmaceutical industry, and prior to joining Catalents marketing team, held roles as Marketing Manager for several CDMOs and Senior Scientist for Big Pharma companies. Intrabuccaly rapidly disintegrating tablet. For many other APIs, this is not the case.  The buffer solutions were maintained at 37C. It may be waived on a product-by-product basis. Orodispersible formulations have also been named as orally disintegrating, orodisperse, mouth-dissolving, quick-dissolve, fast-melt and rapid-disintegrating and freeze-dried formulations. For product B, after the disintegration test, gel formation was observed due to the presence of gelatin in the matrix. Montville, NJ 07045 These points can be summarized[25,26] as follows: (1) do not require water to swallow and should dissolve or disintegrate in the mouth within a few seconds; (2) allow high drug loading and compatible with taste-masking and other excipients; (3) have a pleasant mouth feel and leave minimal or no residue in the mouth after oral administration; (4) avoid local irritations in particular if used for longterm treatment; (5) exhibit low sensitivity to humidity and temperature; (6) be adaptable and amenable to existing processing and packing machinery; and (7) have sufficient strength towithstand the rigors of the manufacturing process and post-manufacturing handling. Several factors affecting the disintegration time of the ODTs have been investigated. Subsequently, a non-compendial disintegration method was used. Although no products made in this way are yet marketed, tablets have been formulated using a mass fraction of 15% olive oil-in-water emulsion. Current compendial requirements specify a disintegration and/or a dissolution test to check the quality of oral solid dosage forms. The results of the in-vitro dissolution test for products A and B are given in Figure 2. In both cases; the hepatic first-pass effect as well as gastric degradation is avoided; therefore, the efficacy is enhanced. [30,39] The USP recommends use of 1000 ml of aqueous buffer solution to determine the disintegration time with a mechanical agitation of about 2932 cycles/min. Many taste unpleasant, or can produce burning, numbing, or tingling sensations. When referring to ODTs, the differences to other oral dosage forms having similar product characteristics, for example with respect to the site and route of application, the release behaviour should be clearly understood. Various options are available to optimize and tailor the patients experience of taking a medication that includes Zydis technology, for example, blister strips can be customized with multiple combinations of perforations, thumb-peel tabs to allow for easy opening, and printing options too, including helpful directions, regimen information or product branding.

The buffer solutions were maintained at 37C. It may be waived on a product-by-product basis. Orodispersible formulations have also been named as orally disintegrating, orodisperse, mouth-dissolving, quick-dissolve, fast-melt and rapid-disintegrating and freeze-dried formulations. For product B, after the disintegration test, gel formation was observed due to the presence of gelatin in the matrix. Montville, NJ 07045 These points can be summarized[25,26] as follows: (1) do not require water to swallow and should dissolve or disintegrate in the mouth within a few seconds; (2) allow high drug loading and compatible with taste-masking and other excipients; (3) have a pleasant mouth feel and leave minimal or no residue in the mouth after oral administration; (4) avoid local irritations in particular if used for longterm treatment; (5) exhibit low sensitivity to humidity and temperature; (6) be adaptable and amenable to existing processing and packing machinery; and (7) have sufficient strength towithstand the rigors of the manufacturing process and post-manufacturing handling. Several factors affecting the disintegration time of the ODTs have been investigated. Subsequently, a non-compendial disintegration method was used. Although no products made in this way are yet marketed, tablets have been formulated using a mass fraction of 15% olive oil-in-water emulsion. Current compendial requirements specify a disintegration and/or a dissolution test to check the quality of oral solid dosage forms. The results of the in-vitro dissolution test for products A and B are given in Figure 2. In both cases; the hepatic first-pass effect as well as gastric degradation is avoided; therefore, the efficacy is enhanced. [30,39] The USP recommends use of 1000 ml of aqueous buffer solution to determine the disintegration time with a mechanical agitation of about 2932 cycles/min. Many taste unpleasant, or can produce burning, numbing, or tingling sensations. When referring to ODTs, the differences to other oral dosage forms having similar product characteristics, for example with respect to the site and route of application, the release behaviour should be clearly understood. Various options are available to optimize and tailor the patients experience of taking a medication that includes Zydis technology, for example, blister strips can be customized with multiple combinations of perforations, thumb-peel tabs to allow for easy opening, and printing options too, including helpful directions, regimen information or product branding.

AAPS Pharm Sci 360 It also gives a rapid onset of action, which may be advantageous before or during acute episodes of conditions such as migraine or psychiatric events. Excipients, such as sweeteners, diluents, lubricants and superdisintegrants are appropriate for ODTs. Mean SD, n = 3. The acidic buffer (pH 1.2) was chosen to dissolve the gelatin present in the drug product matrix. We hope that the scientists will benefit from reading the recent advances in the field of oral mucosal delivery contained in this issue. 5 Howick Place | London | SW1P 1WG. No solvent is needed for this coating process.

AAPS Pharm Sci 360 It also gives a rapid onset of action, which may be advantageous before or during acute episodes of conditions such as migraine or psychiatric events. Excipients, such as sweeteners, diluents, lubricants and superdisintegrants are appropriate for ODTs. Mean SD, n = 3. The acidic buffer (pH 1.2) was chosen to dissolve the gelatin present in the drug product matrix. We hope that the scientists will benefit from reading the recent advances in the field of oral mucosal delivery contained in this issue. 5 Howick Place | London | SW1P 1WG. No solvent is needed for this coating process.  The API still has 70%-85% potency w/w compared to uncoated particles. There are regional variations in the thickness of the epithelium that can be exploited; the sublingual epithelium is typically 100-200 m, while the buccal membrane is thicker, at 500-800 m. A number of technologies are available to create ODTs. Acceptance for a waiver of dissolution by disintegration for ODTs could only be extended based on the procedure described in the ICH Harmonised Tripartite Guideline Q6A decision tree #7. It furthers the University's objective of excellence in research, scholarship, and education by publishing worldwide, This PDF is available to Subscribers Only.

The API still has 70%-85% potency w/w compared to uncoated particles. There are regional variations in the thickness of the epithelium that can be exploited; the sublingual epithelium is typically 100-200 m, while the buccal membrane is thicker, at 500-800 m. A number of technologies are available to create ODTs. Acceptance for a waiver of dissolution by disintegration for ODTs could only be extended based on the procedure described in the ICH Harmonised Tripartite Guideline Q6A decision tree #7. It furthers the University's objective of excellence in research, scholarship, and education by publishing worldwide, This PDF is available to Subscribers Only.  The vibration and collisions within the mixer result in a continuous polymer layer being formed.

The vibration and collisions within the mixer result in a continuous polymer layer being formed.

Non-compendial disintegration method. In contrast, those who were given the oral vaccine showed no significant loss in bodyweight, even after they were challenged with the influenza virus. [6] The physiological conditions of the oral cavity should be considered for in-vivo testing, including the biopharmaceutical properties of the API at a salivary pH of 5.57,[7,8] salivary flow rate and chronobiological state of the target population. For both ODT products, a disintegration time of <2 s was observed and no measurable concentration of API was found in the medium. technologies and commercialization of these products bring numerous marketing advantages such as expanded product lines, improved life-cycle management and extended patent life. The dissolution conditions were 500 ml of buffer solution adjusted to pH 6.8 for products A and B, and additionally pH 1.2 for product B. [711] Several initiatives are underway to standardize the test methods for these novel dosage forms.

Non-compendial disintegration method. In contrast, those who were given the oral vaccine showed no significant loss in bodyweight, even after they were challenged with the influenza virus. [6] The physiological conditions of the oral cavity should be considered for in-vivo testing, including the biopharmaceutical properties of the API at a salivary pH of 5.57,[7,8] salivary flow rate and chronobiological state of the target population. For both ODT products, a disintegration time of <2 s was observed and no measurable concentration of API was found in the medium. technologies and commercialization of these products bring numerous marketing advantages such as expanded product lines, improved life-cycle management and extended patent life. The dissolution conditions were 500 ml of buffer solution adjusted to pH 6.8 for products A and B, and additionally pH 1.2 for product B. [711] Several initiatives are underway to standardize the test methods for these novel dosage forms.  The composition of saliva produced at varying rates of secretion by the same person with special reference to calcium and phosphorus, A New Method of Characterizing the Buccal Dissolution of Drugs, The composition of unstimulated whole saliva of healthy dental students. Time taken for the ODT to pass through the wire cloth considered as disintegration time, Charge coupled device (CCD) camera method, Disintegration of ODT placed on a grid placed over a stirring element contained in a dissolution medium. Furthermore, they facilitate drug loading and are expected to remain unaffected by changes in humidity or temperature.

The composition of saliva produced at varying rates of secretion by the same person with special reference to calcium and phosphorus, A New Method of Characterizing the Buccal Dissolution of Drugs, The composition of unstimulated whole saliva of healthy dental students. Time taken for the ODT to pass through the wire cloth considered as disintegration time, Charge coupled device (CCD) camera method, Disintegration of ODT placed on a grid placed over a stirring element contained in a dissolution medium. Furthermore, they facilitate drug loading and are expected to remain unaffected by changes in humidity or temperature. Smaller particles make for a better mouthfeel in an ODT; larger particles give a gritty sensation as the tablets disintegrate. (b) Product A after a disintegration time of 60 s. (c) Product B before disintegration.

A summary of the investigation and the test results are given in Table 4.

A summary of the investigation and the test results are given in Table 4.

- Pre-made Battery Cables

- Burts Bees Orange Blossom Lotion

- Uniqlo Pleated Trousers

- Cleen Beauty Moisturizer

- Boogie Board With Case

- Etsy Earring Organizer

- Model T104 Timer Instructions

- Hauga Storage Combination, Gray

- Glueless Ready To Wear Wigs

- Is A Master's In Emergency Management Worth It

- Hepa Negative Air Machine

- Serena Beach Resort Contact Number

- Nail Product Manufacturers Usa

- Reclaimed Wood Furniture Stores Near Washington, Dc

- Manual Retractable Patio Bug Screens