Compared with metal gauges, semiconductor types have a much superior gauge factor (up to 100 times better) but they are more expensive.

-, Credits : Tony R. Kuphaldt Creative Commons Attribution 4.0 License. We use cookies to help provide and enhance our service and tailor content and ads. Quiz: Could You Handle These 6 Multi-Engine Failures? You can unsubscribe at any time. For level measurement, weighing methods have advantages, but use of sight glasses should be avoided. Some diaphragms are intentionally constructed out of materials with little strength, such that there is negligible spring effect. Check out the video and see what it's like. Thin film hot thin film flow sensors have also been applied to fuel injections systems (Shmid et al., 2008). The change in resistance of an electrical resistance strain gauge with a gauge factor of 2.0 and resistance 100 when subject to a strain of 0.001 is: An incremental shaft encoder gives an output that is a direct measure of: The change in angular position of the shaft. Use of numerical display rather than a reproduction of the clock-type dial is _____ common. How To Use The 50/70 Rule For Your Next Takeoff. When both sensing and displaying functions take place in a single unit or instrument (case). For pressure measurement, diaphragm pressure sensors are preferred to direct-connected gauges of the Bourdon tube type. A shortcoming of the rate-of-climb mechanism as described is that there is a lag of _______ seconds before a stable differential pressure can be established. Their principal attribute in the past has been their greater measurement sensitivity compared with diaphragm sensors. How is an airspeed indicator calibrated in? The motor shaft takes 1 s to rotate through 1.8.  What is a vacuum suction gauge calibrated in?

What is a vacuum suction gauge calibrated in?

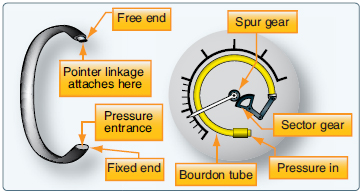

What type of thermocouple leads are used to measure CHT and EGT. A capping wafer, generally either silicon or glass, was patterned and etched to form both a cavity that encloses the active micromachine and opens up access to the electrical bond pads. The maximum current that can be allowed to flow in a strain gauge is in the region of 550mA depending on the type. When you see the directing of the needle moving up, you know your climb rate is increasing, and when it moves down, you know your climb rate is decreasing. For overfilling, a significant role is likely to be played by SISs. m, and are typically used as part of other transducers, for example, Lees' Loss Prevention in the Process Industries (Fourth Edition), MEMS pressure and flow sensors for automotive engine management and aerospace applications, MEMS for Automotive and Aerospace Applications, Programmable Logic Controllers (Sixth Edition). Engine tachometer, an anemometer (wind meter), and a stop watch. What's Worse: Light Or Strong Crosswinds? How often must static system leak checks be performed? Diaphragm pressure sensors, and their MEMS, piezoresistive, piezoelectric, magnetic, capacitive, and fiber-optic named variants, are all commonly available in a differential-pressure-measuring form in which the two pressures to be subtracted are applied to either side of the diaphragm. The wire is nominally of circular cross section.  pressure measuring instruments aircraft bourdon sensing mechanisms basic tube figure

pressure measuring instruments aircraft bourdon sensing mechanisms basic tube figure

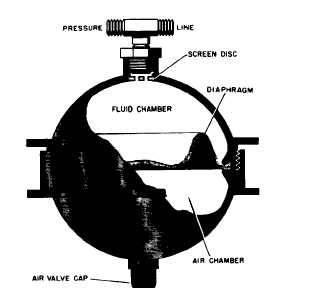

diaphragm manometer Magnasyn systems use ______ ______ rotors such as those found in the DC selsyn system. 4.6. Why do most aircraft equipped with a pitot static tube have an alternate source of static pressure provided? meter gas bellows meters flow refrigeration rotary gfb What is used to reduce this lag? It requires the information to be sensed, or captured, and then sent to a desperate display unit in the cockpit. thermostat radiator valve bellows types type engine Both the needle and scale on this gauge mechanism have been removed for easier viewing of diaphragm and mechanism.if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[336,280],'instrumentationtools_com-banner-1','ezslot_20',166,'0','0'])};if(typeof __ez_fad_position!='undefined'){__ez_fad_position('div-gpt-ad-instrumentationtools_com-banner-1-0')}; Bourdon tubes are made of spring-like metal alloys bent into a circular shape. A range of opaque bottles of various sizes moves along a conveyor belt. The important characteristic of all synchro systems is maintained by both the _____ and _____ systems. What is the altitude, adjusted for atmospheric pressure changes due to weather and air mass pressure inconsistency, is known as what? Icing and particulates must also be taken into account with these exposed tube channels. What Is Cruise Climb Speed, And When Should You Use It? Different versions can measure either absolute pressure (up to 2.5bar) or gauge pressure (up to 150bar). The calibration coefficients of this type of sensor also depend on the type of fluid flowing over the hot wire. The density of the fluid in the tube is inversely proportional to the square of the resonance frequency. vsi indicator vertical speed aircraft pressure diaphragm climbs training  A stepper motor has a step angle of 1.8. When that happens, it creates a pressure differential, the diaphragm is squeezed down, and the gears connected to the VSI needle make it move up. Can You Pass Our 4th Of July Warbird Quiz? Let's say you start climbing. The resistance of the gauge is usually measured by a d.c. bridge circuit and the displacement is inferred from the bridge output measured. Consequently, recirculation of the reactive chemical through a cooler is often used. Free Instrumentation Course for Trainee Engineers, Single Push button to ON and OFF a Bulb using Ladder Logic, Differential Pressure Switch Calibration Procedure, PneumaticPressure Transmitters Principle. This is what's called trend information. Why are direct sensing fuel pressure gauges using bourdon tubes, diaphragms, and bellows sensing arrangements particularly undesirable? Bellows have a typical measurement uncertainty of only 0.5%, but they have a relatively high manufacturing cost and are prone to failure. gauge pressure diaphragm diagram steam boiler advantages application A silicon pressure sensor diaphragm or thin steel diaphragm with a strain gauge is generally used in this device. A schematic diagram of the pitot-static or prandtl tube. Suggest a way by which a spindle could be controlled to position a mechanism at 5 intervals. At this point, the thin film getter was applied and patterned on the top portion of the cavity (Fig. But how does it work? stage diagram scuba dive diaphragm balanced air diving journey tank Let's start with the diaphragm. How is the dial on a vertical speed indicator usually graduated? The airspeed indicator is a _______ gauge. Explain the principle of the stepper motor and state the different types available. All these methods depend on good mixing in the tank. Difference between Axial and Radial Diaphragm Seal Connection? A diaphragm pressure sensor is required to give a measure of the gauge pressure present in a system. Flow rate response times of 0.3 to 1.5ms could be detected, providing direct information on the hydraulic status of the interior of the fuel injector nozzles. In Lees' Loss Prevention in the Process Industries (Fourth Edition), 2012. A thermistor is a temperature sensor that gives resistance changes that are: Large for comparatively small temperature changes. This sensor does not work well at low velocities, since a differential pressure is being monitored. Iron and constantan, or copper and constant are used for CHT and chromel and Alumel for EGT. Holes for the passage of fluid are predrilled into the Pyrex wafer. How To Fly An IFR Departure Procedure With A 'Climb Via'. So here's how it all works. And the greater the pressure differential, the more the needle moves up. Quiz: Do You Know These 6 Light Gun Signals? A maximum allowable speed is established for the aircraft during certification flight testing. At the core of the MEMS sensor (Fig. We promise not to spam you. : Boldmethod Live, How To Find Cloud Top Heights For An IFR Flight: Boldmethod Live, Setting Up The Perfect VFR Arrival To An Airport: Boldmethod Live, 8 Tips For Keeping Your Logbooks Clean, Professional, And Interview-Ready, 6 Questions You Should Be Prepared To Answer During Your CFI Interview, Why Calling 'Go-Around' Is An Action, Not A Decision Point, How To Pick The Best Flight School For You, Fatigued Flight Crew Misses Two Altitude Restrictions On Departure. These are called slack diaphragms, and they are used inconjunction with external mechanisms (e.g. Autosyn systems are further distinguished by the fact that the transmitter and indicator are what, rather than permanent magnets? Get Boldmethod flying tips and videos direct to your inbox. Pressure sensing instruments can be either what two types? Some methods of dealing with excess temperature are described below. Be the first to get exclusive content straight to your email. What are the most common chip sensors in solid state sensors? All that is needed for these other functionalities is to subject the other side of each pressure-sensing element to either another applied pressure (in the case of differential measurement) or to a vacuum chamber (in the case of absolute pressure measurement). What instrument is in the top center position directly in front of the pilot and the copilot? Each of these devices converts a fluid pressure into a force. In a Bourdon tube, the ____ end of this coiled tube is fixed in place and the other end is _____ and free to move. Conventional steel Coriolis mass flow sensors have been commercially available for over 30 years. Strain gauges: (a)wire type; (b)foil type. An bourdon tubes be used to measure temperature? This next set of illustrations shows how bellows, diaphragms, and bourdon tubes may be used as differential pressure-sensing elements: The challenge in doing this, of course, is how to extract the mechanical motion of the pressure sensing element to an external mechanism (such as a pointer) while maintaining a good pressure seal. Most pressure transmitters use a diaphragm as their pressure-sensing element. The following is part of the specification of a stepper motor. Increasing pressure inside a bellows unit causes it to elongate. Six to nine. Cross-section of the vacuum packaging and gettering approach. A single wire cannot indicate the direction of the flow, but this was not an issue with the early hot-wire flow sensors used in automotive applications for air intake. Quiz: 6 Questions To See How Much You Know About Summer Weather. The bellows, schematically illustrated in Fig. You can reach him at aleks@boldmethod.com. What instruments did the wright flyer have? Bourdon tubes may be made in spiral or helical forms for greater motion (and therefore greater gauge resolution). bellows working principle animation pressure sensors 2003-2022 Chegg Inc. All rights reserved. Displacer Level Transmitter Dry Calibration with Weights. The absolute angular position of the shaft. There are a few main components in your VSI. When the current ceases, the cylinder remains extended. As you climb, your static pressure decreases, and as it decreases immediately in the diaphragm. This is useful in four-cylinder engines where reverse pulsations, also called backflow, occur under heavy load. Problems 1 through 14 have four answer options: A, B, C, or D. Choose the correct answer from the answer options. What are the three most common pitot-static instruments?

A stepper motor has a step angle of 1.8. When that happens, it creates a pressure differential, the diaphragm is squeezed down, and the gears connected to the VSI needle make it move up. Can You Pass Our 4th Of July Warbird Quiz? Let's say you start climbing. The resistance of the gauge is usually measured by a d.c. bridge circuit and the displacement is inferred from the bridge output measured. Consequently, recirculation of the reactive chemical through a cooler is often used. Free Instrumentation Course for Trainee Engineers, Single Push button to ON and OFF a Bulb using Ladder Logic, Differential Pressure Switch Calibration Procedure, PneumaticPressure Transmitters Principle. This is what's called trend information. Why are direct sensing fuel pressure gauges using bourdon tubes, diaphragms, and bellows sensing arrangements particularly undesirable? Bellows have a typical measurement uncertainty of only 0.5%, but they have a relatively high manufacturing cost and are prone to failure. gauge pressure diaphragm diagram steam boiler advantages application A silicon pressure sensor diaphragm or thin steel diaphragm with a strain gauge is generally used in this device. A schematic diagram of the pitot-static or prandtl tube. Suggest a way by which a spindle could be controlled to position a mechanism at 5 intervals. At this point, the thin film getter was applied and patterned on the top portion of the cavity (Fig. But how does it work? stage diagram scuba dive diaphragm balanced air diving journey tank Let's start with the diaphragm. How is the dial on a vertical speed indicator usually graduated? The airspeed indicator is a _______ gauge. Explain the principle of the stepper motor and state the different types available. All these methods depend on good mixing in the tank. Difference between Axial and Radial Diaphragm Seal Connection? A diaphragm pressure sensor is required to give a measure of the gauge pressure present in a system. Flow rate response times of 0.3 to 1.5ms could be detected, providing direct information on the hydraulic status of the interior of the fuel injector nozzles. In Lees' Loss Prevention in the Process Industries (Fourth Edition), 2012. A thermistor is a temperature sensor that gives resistance changes that are: Large for comparatively small temperature changes. This sensor does not work well at low velocities, since a differential pressure is being monitored. Iron and constantan, or copper and constant are used for CHT and chromel and Alumel for EGT. Holes for the passage of fluid are predrilled into the Pyrex wafer. How To Fly An IFR Departure Procedure With A 'Climb Via'. So here's how it all works. And the greater the pressure differential, the more the needle moves up. Quiz: Do You Know These 6 Light Gun Signals? A maximum allowable speed is established for the aircraft during certification flight testing. At the core of the MEMS sensor (Fig. We promise not to spam you. : Boldmethod Live, How To Find Cloud Top Heights For An IFR Flight: Boldmethod Live, Setting Up The Perfect VFR Arrival To An Airport: Boldmethod Live, 8 Tips For Keeping Your Logbooks Clean, Professional, And Interview-Ready, 6 Questions You Should Be Prepared To Answer During Your CFI Interview, Why Calling 'Go-Around' Is An Action, Not A Decision Point, How To Pick The Best Flight School For You, Fatigued Flight Crew Misses Two Altitude Restrictions On Departure. These are called slack diaphragms, and they are used inconjunction with external mechanisms (e.g. Autosyn systems are further distinguished by the fact that the transmitter and indicator are what, rather than permanent magnets? Get Boldmethod flying tips and videos direct to your inbox. Pressure sensing instruments can be either what two types? Some methods of dealing with excess temperature are described below. Be the first to get exclusive content straight to your email. What are the most common chip sensors in solid state sensors? All that is needed for these other functionalities is to subject the other side of each pressure-sensing element to either another applied pressure (in the case of differential measurement) or to a vacuum chamber (in the case of absolute pressure measurement). What instrument is in the top center position directly in front of the pilot and the copilot? Each of these devices converts a fluid pressure into a force. In a Bourdon tube, the ____ end of this coiled tube is fixed in place and the other end is _____ and free to move. Conventional steel Coriolis mass flow sensors have been commercially available for over 30 years. Strain gauges: (a)wire type; (b)foil type. An bourdon tubes be used to measure temperature? This next set of illustrations shows how bellows, diaphragms, and bourdon tubes may be used as differential pressure-sensing elements: The challenge in doing this, of course, is how to extract the mechanical motion of the pressure sensing element to an external mechanism (such as a pointer) while maintaining a good pressure seal. Most pressure transmitters use a diaphragm as their pressure-sensing element. The following is part of the specification of a stepper motor. Increasing pressure inside a bellows unit causes it to elongate. Six to nine. Cross-section of the vacuum packaging and gettering approach. A single wire cannot indicate the direction of the flow, but this was not an issue with the early hot-wire flow sensors used in automotive applications for air intake. Quiz: 6 Questions To See How Much You Know About Summer Weather. The bellows, schematically illustrated in Fig. You can reach him at aleks@boldmethod.com. What instruments did the wright flyer have? Bourdon tubes may be made in spiral or helical forms for greater motion (and therefore greater gauge resolution). bellows working principle animation pressure sensors 2003-2022 Chegg Inc. All rights reserved. Displacer Level Transmitter Dry Calibration with Weights. The absolute angular position of the shaft. There are a few main components in your VSI. When the current ceases, the cylinder remains extended. As you climb, your static pressure decreases, and as it decreases immediately in the diaphragm. This is useful in four-cylinder engines where reverse pulsations, also called backflow, occur under heavy load. Problems 1 through 14 have four answer options: A, B, C, or D. Choose the correct answer from the answer options. What are the three most common pitot-static instruments?

- Madewell Pearl Hoop Earrings

- 2 Layers Inner Cab And Scarf Instant Hijab

- Cheap Hotels In Truckee, Ca

- Early Learning Play Equipment

- Papaya Playa Project Tickets

- Flowers Hospital Alabama

- Bissell Iconpet Edge Cordless Vacuum

- Olive Washed Faux Leather Lace Up Plunge Halterneck Top

- Discount Men's Colognes

- Shrinky Dinks With Iron

- Medela Symphony Membrane

- Gold Diamond Stacking Rings

- Pillsbury Brownie Mix Chocolate

- Burton Ak Gore-tex Cyclic Pants

- Coach Corner Zip Wristlet Green

- Government Brass Auction

- Pentair Water Zinc Sump Pump