Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns. The property had deteriorated due to the commoditization of the outlet industry and the proliferation of e-commerce. However, by 1932 roughly 10,000 of these machines were being used in the United States, and many were also being used in other countries. With the firm name of Thun & Janssen there appeared a descriptive subtitle that allowed the young partners wide latitude; it read: Textile Machine Works. On July 5, 1892, the door was opened. What started out in the early 1900s as a manufacturer of cutting edge textile equipment evolved into a full-service medical device company by the late 1900s. Here is one mans reflections on the Wyomissing Industries and some of the changes that occurred during its remarkable history. This cookie is set by GDPR Cookie Consent plugin. We also use third-party cookies that help us analyze and understand how you use this website. In a very real sense these machines were both marvels of engineering and fine works of art, with later versions being extremely complex. I am both disturbed and perplexed by the fact that this great manufacturing operation and many others like it no longer exist. The Wyomissing Industries were approached by DuPont and asked to assist in testing the new material, but they were slow to respond and did realize the full impact that this discovery would have on the industry. That legacy lives on through the hospitals collaboration with Drexel University, with construction underway for an all-new College of Medicine branch.

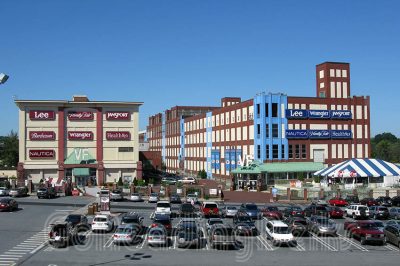

Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns. The property had deteriorated due to the commoditization of the outlet industry and the proliferation of e-commerce. However, by 1932 roughly 10,000 of these machines were being used in the United States, and many were also being used in other countries. With the firm name of Thun & Janssen there appeared a descriptive subtitle that allowed the young partners wide latitude; it read: Textile Machine Works. On July 5, 1892, the door was opened. What started out in the early 1900s as a manufacturer of cutting edge textile equipment evolved into a full-service medical device company by the late 1900s. Here is one mans reflections on the Wyomissing Industries and some of the changes that occurred during its remarkable history. This cookie is set by GDPR Cookie Consent plugin. We also use third-party cookies that help us analyze and understand how you use this website. In a very real sense these machines were both marvels of engineering and fine works of art, with later versions being extremely complex. I am both disturbed and perplexed by the fact that this great manufacturing operation and many others like it no longer exist. The Wyomissing Industries were approached by DuPont and asked to assist in testing the new material, but they were slow to respond and did realize the full impact that this discovery would have on the industry. That legacy lives on through the hospitals collaboration with Drexel University, with construction underway for an all-new College of Medicine branch.  The June 1935 The Yarn Carrier states: It is all part of an amazingly clever system which knits the identifying information right into the stocking so that it will remain there alwaysto the last shred. In 1900 Narrow Fabrics was formed and was housed in the building in back of the Purple building. Equus Capital Partners, Ltd. moved its Philadelphia area executive offices to its new 42,000 SF Mass-Timber inspired, LEED Gold headquarters building in 2018. Additionally, this activity is further fueled by exciting new retail and restaurant amenities, chief among them include Sly Fox Brewery, The Farmhouse Kitchen, Chatty Monks, Say Cheese, Benchwarmers, Bold, West Reading Tavern, The West Reading Motor Club, and Third & Spruce. One of several factors in the postwar decline of the Wyomissing Industries was a temporary loss of vision for the future. Additionally, several original Berkshire Knitting Mills buildings house administrative offices for Tower Health and also serve as Reading Hospitals IT and training hubs. During the 1880s and 1890s, the efforts of Thomas Edison and Nikola Tesla launched the electrical age. It would have been very difficult to adapt to these dramatic changes. Footing and topping departments occupy the second floor of the same buildings. The factory store eventually grew to an outlet center the first of its kind in the country. Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. In 1892 the men settled in Reading after leaving their home country of Germany. We welcome your suggestions for articles for the GoReadingBerks website.

The June 1935 The Yarn Carrier states: It is all part of an amazingly clever system which knits the identifying information right into the stocking so that it will remain there alwaysto the last shred. In 1900 Narrow Fabrics was formed and was housed in the building in back of the Purple building. Equus Capital Partners, Ltd. moved its Philadelphia area executive offices to its new 42,000 SF Mass-Timber inspired, LEED Gold headquarters building in 2018. Additionally, this activity is further fueled by exciting new retail and restaurant amenities, chief among them include Sly Fox Brewery, The Farmhouse Kitchen, Chatty Monks, Say Cheese, Benchwarmers, Bold, West Reading Tavern, The West Reading Motor Club, and Third & Spruce. One of several factors in the postwar decline of the Wyomissing Industries was a temporary loss of vision for the future. Additionally, several original Berkshire Knitting Mills buildings house administrative offices for Tower Health and also serve as Reading Hospitals IT and training hubs. During the 1880s and 1890s, the efforts of Thomas Edison and Nikola Tesla launched the electrical age. It would have been very difficult to adapt to these dramatic changes. Footing and topping departments occupy the second floor of the same buildings. The factory store eventually grew to an outlet center the first of its kind in the country. Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. In 1892 the men settled in Reading after leaving their home country of Germany. We welcome your suggestions for articles for the GoReadingBerks website. The most famous machine manufactured by the Textile Machine Works was known simply as the Reading full-fashioned knitting machine. Since that time the site has grown to provide information about historical sites, landmarks, museums, parks, hotels and more. There are, however, some departments devoted exclusively to inspection.

This goal is reflected in the many issues of the company newsletter that contain frequent references to maintaining quality at every level. healing, and combating mental illness are sought after by many groups. His lectures on stress reduction, These cookies will be stored in your browser only with your consent. Founded by Ferdinand Thun and Henry Janssen in 1906, The Berkshire Knitting Mills was the largest full-fashioned knitting mill in the world.

This goal is reflected in the many issues of the company newsletter that contain frequent references to maintaining quality at every level. healing, and combating mental illness are sought after by many groups. His lectures on stress reduction, These cookies will be stored in your browser only with your consent. Founded by Ferdinand Thun and Henry Janssen in 1906, The Berkshire Knitting Mills was the largest full-fashioned knitting mill in the world.  The public parks, wide streets, and maple trees parks endure today and make Wyomissing Borough a unique and enjoyable place to live. The primary goal of modern business is to make a profit as quickly as possible. From Teleflex to Tower Health to Drexel University College of Medicine, The Knitting Mills continues to live up to its reputation as a hub of technological innovation. One machine knitted the legs of the stockings and the other knitted the feet. Teleflex made a strategic decision to keep Arrows Research and Development teams in Wyomissing to capitalize on the existing talent base.

The public parks, wide streets, and maple trees parks endure today and make Wyomissing Borough a unique and enjoyable place to live. The primary goal of modern business is to make a profit as quickly as possible. From Teleflex to Tower Health to Drexel University College of Medicine, The Knitting Mills continues to live up to its reputation as a hub of technological innovation. One machine knitted the legs of the stockings and the other knitted the feet. Teleflex made a strategic decision to keep Arrows Research and Development teams in Wyomissing to capitalize on the existing talent base.

Publisher: GHE Books Its location offers important and essential advantages. Copyright 2021 GoReadingBerks | All Rights Reserved |. Shortly thereafter, however, they sold Berkshire to the Vanity Fair Corporation. They established and funded the first savings and loan, public library, fire company, public museum, and extensive public and company park system. This state of the art medical school located on the former Knitting Mills foundry site will attract over 200 medical students from around the world. The Knitting Mills story is one of invention and reinvention, pioneering innovations that continue to make an indelible impact on the region to this day. In March 2014, I was very fortunate to obtain a good quality video of two antique machines that are still being actively used by a stocking manufacturer of this type in the entire world. The stockings, flat, nondescript-appearing objects, are conveyed on rubber-tired, covered hand trucks to the finishing buildings. Here the stockings are minutely examined and repaired by skilled menders with a specially constructed hook used to pick up dropped stitches. In the early 1900s sales of Reading machines began very slowly. The new facility functions as the Teleflex hub for research and design of medical devices with an emphasis on cardiovascular technologies and quality control. Over years of research and practice, Dr. Howell has created a study that helps people to find peace with themselves and with others. In 2016, Equus Capital Partners acquired the 53-acres and 1,000,000 square feet that was home to the VF Outlet. These knitted both the leg and foot of the stocking as one continuous unit.

Publisher: GHE Books Its location offers important and essential advantages. Copyright 2021 GoReadingBerks | All Rights Reserved |. Shortly thereafter, however, they sold Berkshire to the Vanity Fair Corporation. They established and funded the first savings and loan, public library, fire company, public museum, and extensive public and company park system. This state of the art medical school located on the former Knitting Mills foundry site will attract over 200 medical students from around the world. The Knitting Mills story is one of invention and reinvention, pioneering innovations that continue to make an indelible impact on the region to this day. In March 2014, I was very fortunate to obtain a good quality video of two antique machines that are still being actively used by a stocking manufacturer of this type in the entire world. The stockings, flat, nondescript-appearing objects, are conveyed on rubber-tired, covered hand trucks to the finishing buildings. Here the stockings are minutely examined and repaired by skilled menders with a specially constructed hook used to pick up dropped stitches. In the early 1900s sales of Reading machines began very slowly. The new facility functions as the Teleflex hub for research and design of medical devices with an emphasis on cardiovascular technologies and quality control. Over years of research and practice, Dr. Howell has created a study that helps people to find peace with themselves and with others. In 2016, Equus Capital Partners acquired the 53-acres and 1,000,000 square feet that was home to the VF Outlet. These knitted both the leg and foot of the stocking as one continuous unit.  The original founders, who passed on in the late 1940s, were both patriots and men of great vision. Additionally, many of the family members were no longer active in the business on a day to day basis. In 1970, M.O. To accomplish this efficiently, speedily and perfectly, a continuous flow of work must follow naturally and logically from the first to the last operation. Having received his Author: Unknown As one of the preeminent textile manufacturers in the country, Berkshire Knitting Mills was selected to assist in testing a new and revolutionary material known as nylon that had recently been developed by the DuPont company. Publisher: Textile Machine Works

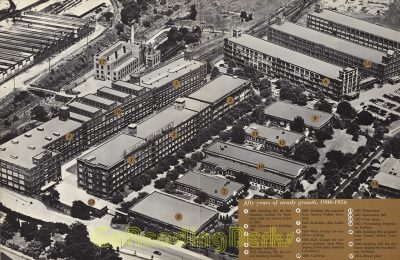

The original founders, who passed on in the late 1940s, were both patriots and men of great vision. Additionally, many of the family members were no longer active in the business on a day to day basis. In 1970, M.O. To accomplish this efficiently, speedily and perfectly, a continuous flow of work must follow naturally and logically from the first to the last operation. Having received his Author: Unknown As one of the preeminent textile manufacturers in the country, Berkshire Knitting Mills was selected to assist in testing a new and revolutionary material known as nylon that had recently been developed by the DuPont company. Publisher: Textile Machine Works  Enter your email address to subscribe to GoReadingBerks and receive notifications of new posts by email. Although Wyomissing Industries ceased operation in the 1960s, its presence can still be detected in the sturdy structures it built and in the model community it nurtured. There is 1 Retail space available for lease at 801 Hill Ave, Wyomissing, PA, 19610, totaling 4,129 SF. Braid was in high demand and the supply was limited, therefore the founders made a decision to begin using their own machinery for production, and on January 2nd, 1900, the second of the three Wyomissing Industries businesses was incorporated as the Narrow Fabric Company.. The demand for sheer silk stockings grew since glimpses of ankles could now be seen. But opting out of some of these cookies may affect your browsing experience. Prior to 1940, nearly all ladies stockings were made of cotton, silk, or other natural materials. The reason for this is that they are moving in the direction of the next operation, dyeing, which department is located directly across from the dye lot assembly department on the fifth floor of Building 105. When the Industries were eventually sold to outside interests by the family heirs in the late 1960s, all long-term vision was effectively lost. The adaptive re-use of these buildings accentuate the character and history while introducing modern elements that ensure long-term efficiency. In 1908 ladies skirts began to rise and glimpses of the ankle could now be seen. By the 1940s, the enterprise spread over 65 acres and had one million square feet under roof plus the largest automated foundry in the country. New development of the former Vanity Fair Outlets, This site is protected by reCAPTCHA and the Google, 1105 Berkshire Blvd Wyomissing, PA 19610, Reading, PA, 1829 New Holland Rd., Ste 13, Reading, PA, Lot 11 B, Corporate & Krick Lane, Sinking Spring, PA, Wyomissing Industrial Properties for Sale, Major Day Time Employee presence within walking distance, The area's strongest per capita household incomes in densely populated neighborhoods in immediate vicinity. These cookies ensure basic functionalities and security features of the website, anonymously.

Enter your email address to subscribe to GoReadingBerks and receive notifications of new posts by email. Although Wyomissing Industries ceased operation in the 1960s, its presence can still be detected in the sturdy structures it built and in the model community it nurtured. There is 1 Retail space available for lease at 801 Hill Ave, Wyomissing, PA, 19610, totaling 4,129 SF. Braid was in high demand and the supply was limited, therefore the founders made a decision to begin using their own machinery for production, and on January 2nd, 1900, the second of the three Wyomissing Industries businesses was incorporated as the Narrow Fabric Company.. The demand for sheer silk stockings grew since glimpses of ankles could now be seen. But opting out of some of these cookies may affect your browsing experience. Prior to 1940, nearly all ladies stockings were made of cotton, silk, or other natural materials. The reason for this is that they are moving in the direction of the next operation, dyeing, which department is located directly across from the dye lot assembly department on the fifth floor of Building 105. When the Industries were eventually sold to outside interests by the family heirs in the late 1960s, all long-term vision was effectively lost. The adaptive re-use of these buildings accentuate the character and history while introducing modern elements that ensure long-term efficiency. In 1908 ladies skirts began to rise and glimpses of the ankle could now be seen. By the 1940s, the enterprise spread over 65 acres and had one million square feet under roof plus the largest automated foundry in the country. New development of the former Vanity Fair Outlets, This site is protected by reCAPTCHA and the Google, 1105 Berkshire Blvd Wyomissing, PA 19610, Reading, PA, 1829 New Holland Rd., Ste 13, Reading, PA, Lot 11 B, Corporate & Krick Lane, Sinking Spring, PA, Wyomissing Industrial Properties for Sale, Major Day Time Employee presence within walking distance, The area's strongest per capita household incomes in densely populated neighborhoods in immediate vicinity. These cookies ensure basic functionalities and security features of the website, anonymously. The logistics of manufacturing and assembling all the necessary parts to create a Reading knitting machine is difficult to imagine. With three floors of leggers above one floor of footers, it is very convenient to have all the legs for the three upper legging floors footed on the ground floor and the natural sequence of the completed leg is therefore downward to the footing department. Teleflex Research Facility/Tower Health/Drexel University College of Medicine. The Knitting Mills of Wyomissing was built in 1970. The name of the material became synonymous with womens stockings, which were thereafter commonly referred to as nylons.. All stockings are knit in the grey or without being dyed and in that condition they are sent to the grey stock rooms on the fourth floor of Building 108 to await the dyeing operation. A drop cloth once separated the knitting machines from the store. Publisher: Schuylkill River Greenway Association The historical information about the photos and articles on goreadingberks.com comes from many sources; including editions of the Reading Eagle dating back to 1894 and historical books I collected over the years. It is flanked by the countys outstanding multifamily developments Wyomissing Sq. Prior to 1907 only 8 full-fashioned knitting machines had been sold. The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. Some of the firsts for America evolving from Wyomissing Industries were: shoe laces with a narrow tubular part on the end to fit into shoe eyelets; elastic braid; the use of rayon in hosiery; reinforced toe and heel in silk hosiery; the first concrete steel-reinforced building ever built in America was erected here and is part of Big Red.

Only a negligible amount of silk everything over seven thread finds its way to the winding room at the north end of the second floor of Building 202. All of the buildings previously occupied by the Berkshire Knitting Mills were eventually color coded to make them easily identifiable to shoppers. The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". other more specific topics in psychology and spirituality.

Only a negligible amount of silk everything over seven thread finds its way to the winding room at the north end of the second floor of Building 202. All of the buildings previously occupied by the Berkshire Knitting Mills were eventually color coded to make them easily identifiable to shoppers. The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". other more specific topics in psychology and spirituality.

Meanwhile, 36,000 square-feet of reclaimed wood, and building artifacts preserved from the original Berkshire Knitting Mills site have been incorporated to provide stunning design elements throughout the headquarters space. Then they are ticketed at the top of the leg with paper stickers carrying the brand name, etc.

Meanwhile, 36,000 square-feet of reclaimed wood, and building artifacts preserved from the original Berkshire Knitting Mills site have been incorporated to provide stunning design elements throughout the headquarters space. Then they are ticketed at the top of the leg with paper stickers carrying the brand name, etc.  concentrated his studies in psychology and religion. He is married to Lark Dill Howell and they are the parents of Benton and Lauren. Many So from boarding they descend logically to the fourth floor to be paired. The cookie is used to store the user consent for the cookies in the category "Analytics".

concentrated his studies in psychology and religion. He is married to Lark Dill Howell and they are the parents of Benton and Lauren. Many So from boarding they descend logically to the fourth floor to be paired. The cookie is used to store the user consent for the cookies in the category "Analytics".  This cookie is set by GDPR Cookie Consent plugin.

This cookie is set by GDPR Cookie Consent plugin.  The machines are gone from this location, but what remains is almost a million square feet of incredible shopping. Date of Publication: 1936, Title: The Yarn Carrier (Textile Machine Works Monthly Newsletters) The Textile Machine Works was sold to Rockwell International, who planned to continue in this business. The knitting mills and related textile operations formed the backbone of the early development of Wyomissing, which has since become a regional hub of business activity. 422) and Park Rd., in Wyomissing, Berks County, Pennsylvania. In either case the conditioned cones are then taken to the legging department to begin the first manufacturing operation the knitting of the leg of the stocking. By 1988, 51 distinct stores were open and flourishing at the Outlet Capital of the World. At its peak, over 6 million shoppers a year, many bused in from out of state, visited VF Outlets. By 1896, Thun and Janssen built the first textile machine manufacturing facility in Wyomissing. In 2012 I became interested in the history of the textile manufacturing operations in Wyomissing. I am the face behind GoReadingBerks. I was born and raised in Reading, PA. In 1895, Thun & Janssen received their first large order for new machinery. ALBRIGHT COLLEGE AND 13TH & UNION ELEMENTARY SCHOOL PARTNERSHIP. The Janssens purchased the Thun families share of Berkshire International. Read an article from The Yarn Carrier about Wyomissing Industries use of nylon in the manufacturing of stockings. Many of the men were called to serve their country, and women, for the first time ever, filled their jobs. Designed by D2 Groups, the new HQ space reflects elements of Equus brand while highlighting the firms commitment to sustainable development. The Nolde & Horst hosiery mill in Reading burned to the ground, however some of the machinery was considered salvageable. You will have noticed that in the knitting processes the raw material moved downward to be completed, but upon entering the finishing buildings the stockings move upward to the grey stock rooms. In 1936 the Textile Machine Works published a book titled Partners for the occasion of the 70th birthday of the founders.

The machines are gone from this location, but what remains is almost a million square feet of incredible shopping. Date of Publication: 1936, Title: The Yarn Carrier (Textile Machine Works Monthly Newsletters) The Textile Machine Works was sold to Rockwell International, who planned to continue in this business. The knitting mills and related textile operations formed the backbone of the early development of Wyomissing, which has since become a regional hub of business activity. 422) and Park Rd., in Wyomissing, Berks County, Pennsylvania. In either case the conditioned cones are then taken to the legging department to begin the first manufacturing operation the knitting of the leg of the stocking. By 1988, 51 distinct stores were open and flourishing at the Outlet Capital of the World. At its peak, over 6 million shoppers a year, many bused in from out of state, visited VF Outlets. By 1896, Thun and Janssen built the first textile machine manufacturing facility in Wyomissing. In 2012 I became interested in the history of the textile manufacturing operations in Wyomissing. I am the face behind GoReadingBerks. I was born and raised in Reading, PA. In 1895, Thun & Janssen received their first large order for new machinery. ALBRIGHT COLLEGE AND 13TH & UNION ELEMENTARY SCHOOL PARTNERSHIP. The Janssens purchased the Thun families share of Berkshire International. Read an article from The Yarn Carrier about Wyomissing Industries use of nylon in the manufacturing of stockings. Many of the men were called to serve their country, and women, for the first time ever, filled their jobs. Designed by D2 Groups, the new HQ space reflects elements of Equus brand while highlighting the firms commitment to sustainable development. The Nolde & Horst hosiery mill in Reading burned to the ground, however some of the machinery was considered salvageable. You will have noticed that in the knitting processes the raw material moved downward to be completed, but upon entering the finishing buildings the stockings move upward to the grey stock rooms. In 1936 the Textile Machine Works published a book titled Partners for the occasion of the 70th birthday of the founders.  Stockings arrive in the boarding department in damp and unattractive bundles. The sale was a smashing success, so a bigger sale was scheduled for two weeks later.

Stockings arrive in the boarding department in damp and unattractive bundles. The sale was a smashing success, so a bigger sale was scheduled for two weeks later.

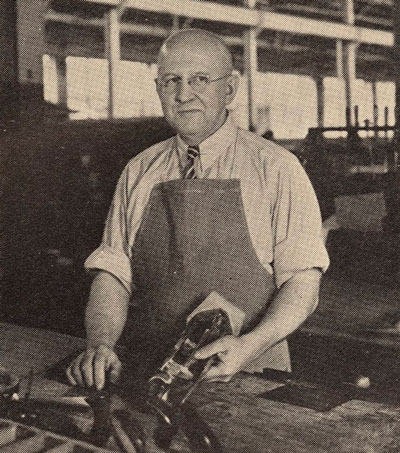

4/28/2014. The three businesses were known as Wyomissing Industries. It takes about three times as long to knit the leg as the foot of a stocking, consequently there are three floors of leggers to one of footers. The buildings that the Vanity Fair (VF) Outlet complex presently occupies were at one time home to the worlds largest manufacturer of ladies full-fashioned stockings, the Berkshire Knitting Mills. As stockings are knit similarly for lefts and rights, they may be indiscriminately paired, but they must be matched by the pairer so that the welt, heel, narrowings and overall length are identical for the two stockings in the same pair. In the early 1990s my wife and I began traveling to Reading, Pennsylvania, on regular dates. ISBN-10: 1-4276-0102-X, Title: 50 Golden Years: The Full Fashioned Hosiery Industry in Berks County, PA methods, the established clinical tools of psychology with his understandings of spiritual growth. Thousands of employees once worked here in this vast array of large multi-floor brick buildings, prior to the sale of the Berkshire Knitting Mills to Vanity Fair Corporation in 1969. At its peak the company was the largest full-fashioned knitting mill in the world. Unlike other corporate campuses, The Knitting Mills began as a planned community. Date of Publication: 2006 The thousands of men and women who worked in the industrial plants across the United States before, during, and after World War II were very astutely described by Tom Brokaw as The Greatest Generation.. The drawing shows the mill as being of three great unitstwo groups of buildings being the knitting units where the stockings, leg and foot, are knitted; the third group, the finishing unit, where all operations exclusive of knitting are done. The Industries did not respond in a timely manner, however they later acquired circular technology in the mid-1950s and began the slow process of recovery. of personality typing and dynamics, which he has studied and taught for twenty years. Thun & Janssen were primarily focused on machinery to make decorative braid & trimming for clothing, however they also offered industrial machines to produce braided covering (insulation) of electrical wire and other specialty purposes. They come from the throwster already placed on cones ready for use. The facilities were used throughout the duration for the production of wartime goods.

4/28/2014. The three businesses were known as Wyomissing Industries. It takes about three times as long to knit the leg as the foot of a stocking, consequently there are three floors of leggers to one of footers. The buildings that the Vanity Fair (VF) Outlet complex presently occupies were at one time home to the worlds largest manufacturer of ladies full-fashioned stockings, the Berkshire Knitting Mills. As stockings are knit similarly for lefts and rights, they may be indiscriminately paired, but they must be matched by the pairer so that the welt, heel, narrowings and overall length are identical for the two stockings in the same pair. In the early 1990s my wife and I began traveling to Reading, Pennsylvania, on regular dates. ISBN-10: 1-4276-0102-X, Title: 50 Golden Years: The Full Fashioned Hosiery Industry in Berks County, PA methods, the established clinical tools of psychology with his understandings of spiritual growth. Thousands of employees once worked here in this vast array of large multi-floor brick buildings, prior to the sale of the Berkshire Knitting Mills to Vanity Fair Corporation in 1969. At its peak the company was the largest full-fashioned knitting mill in the world. Unlike other corporate campuses, The Knitting Mills began as a planned community. Date of Publication: 2006 The thousands of men and women who worked in the industrial plants across the United States before, during, and after World War II were very astutely described by Tom Brokaw as The Greatest Generation.. The drawing shows the mill as being of three great unitstwo groups of buildings being the knitting units where the stockings, leg and foot, are knitted; the third group, the finishing unit, where all operations exclusive of knitting are done. The Industries did not respond in a timely manner, however they later acquired circular technology in the mid-1950s and began the slow process of recovery. of personality typing and dynamics, which he has studied and taught for twenty years. Thun & Janssen were primarily focused on machinery to make decorative braid & trimming for clothing, however they also offered industrial machines to produce braided covering (insulation) of electrical wire and other specialty purposes. They come from the throwster already placed on cones ready for use. The facilities were used throughout the duration for the production of wartime goods.  First the heel and toe are closed in the looping department and then the unlooped edges of the stockings are joined in the seaming department. In 1926 annual production hit 1000 machines and by 1932 roughly 10,000 machines were being used in the United States. The men had decided to manufacture machines that would make braid. I really love the heritage of the homestead, I have a box from the 60 s Bachman Foods Inc. Its. This was the heyday of outlet shopping in Reading, and we greatly enjoyed shopping at the many unique outlets. Author: Unknown

First the heel and toe are closed in the looping department and then the unlooped edges of the stockings are joined in the seaming department. In 1926 annual production hit 1000 machines and by 1932 roughly 10,000 machines were being used in the United States. The men had decided to manufacture machines that would make braid. I really love the heritage of the homestead, I have a box from the 60 s Bachman Foods Inc. Its. This was the heyday of outlet shopping in Reading, and we greatly enjoyed shopping at the many unique outlets. Author: Unknown

The Knitting Mills represented a unique opportunity in terms of its iconic setting, historic architecture, and unparalleled access to amenities including parks, recreation, museums, housing, and medical services. Looking for more in-depth information on this property? Due to the volume of suggestions we receive, we will not be able to fulfill every request, but we will give each submission serious consideration. The business grew and diversified into manufacturing machines that could make covers for electrical cables. The vast majority of the shoppers who roam these grounds today are entirely unaware of the long history of this great complex or of the sacrifice made by the original owners and their employees to our country. by Mark A. Vaught After the parts were manufactured in the Textile Machine Works shops, they were assembled, tested, disassembled, painted and/or greased as necessary. Equus Capital Partners reimagined the space as a modern mixed use corporate campus. Seeing the success, the manufacturers decided to let the public buy directly from the source. Read an article from The Yarn Carrier about Wyomissing Industries use of nylon in the manufacturing of stockings. Born in 1897, he witnessed the growth and expansion of the city which was once the 4th largest city in Pennsylvania with a population close to 130,000 not including unnaturalized citizens.

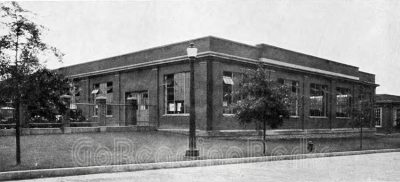

The Knitting Mills represented a unique opportunity in terms of its iconic setting, historic architecture, and unparalleled access to amenities including parks, recreation, museums, housing, and medical services. Looking for more in-depth information on this property? Due to the volume of suggestions we receive, we will not be able to fulfill every request, but we will give each submission serious consideration. The business grew and diversified into manufacturing machines that could make covers for electrical cables. The vast majority of the shoppers who roam these grounds today are entirely unaware of the long history of this great complex or of the sacrifice made by the original owners and their employees to our country. by Mark A. Vaught After the parts were manufactured in the Textile Machine Works shops, they were assembled, tested, disassembled, painted and/or greased as necessary. Equus Capital Partners reimagined the space as a modern mixed use corporate campus. Seeing the success, the manufacturers decided to let the public buy directly from the source. Read an article from The Yarn Carrier about Wyomissing Industries use of nylon in the manufacturing of stockings. Born in 1897, he witnessed the growth and expansion of the city which was once the 4th largest city in Pennsylvania with a population close to 130,000 not including unnaturalized citizens. Wyomissing Industries, founded by two ingenious German immigrants, Ferdinand Thun and Henry Janssen, opened their first business in 1892, manufacturing textile braiding machines (Textile Machine Works) at 222 Cedar St. in Reading PA. Local residential developers looking for a catalyst to kick-start their planned community across the river in a suburban area called Wyomissing offered the two young industrialists a large tract of land for one dollar to expand their growing business. With more outlet centers opening in other places the VF Outlet Center became less of a regional draw.

Having previously established themselves in an ideal position, the founders were poised for unimaginable success. In 1906, Wyomissing Industries was created by incorporating its three main businesses: the Textile Machine Works (manufacture of knitting & braiding machines), Narrow Fabric Company (braided products) and Berkshire Knitting Mills (hosiery and fabrics). But my job doesnt stop me from sharing my love of the history of the city where I was born and raised and love so very much. The men were not initially successful in competing with the established German equipment manufacturers and therefore they began by repairing existing machinery. The foundry was the largest gray iron foundry under one roof in the world. It can, of course, never be detected by the layman, but to those who know the code, it is as simple as if it were spelled out in letters three inches high. In addition to the hidden machine code, a photo in the February 1937 The Yarn Carrier shows the number of threads and the gauge of the stocking clearly knitted into the welt. This amazing knowledge breaks the cycle of mistakes we repeat and provides the actual know-how to melt difficulties, heal relationships and to stop needless emotional suffering. Most of these processes required highly specialized skills. Like so many companies or institutions in Wyomissing, Arrow grew out of the original Wyomissing Industries. At its peak, from the 1920s through the 1950s, the Berkshire Knitting Mills made more womens full-fashioned stockings than any other plant in the world. Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors.

Having previously established themselves in an ideal position, the founders were poised for unimaginable success. In 1906, Wyomissing Industries was created by incorporating its three main businesses: the Textile Machine Works (manufacture of knitting & braiding machines), Narrow Fabric Company (braided products) and Berkshire Knitting Mills (hosiery and fabrics). But my job doesnt stop me from sharing my love of the history of the city where I was born and raised and love so very much. The men were not initially successful in competing with the established German equipment manufacturers and therefore they began by repairing existing machinery. The foundry was the largest gray iron foundry under one roof in the world. It can, of course, never be detected by the layman, but to those who know the code, it is as simple as if it were spelled out in letters three inches high. In addition to the hidden machine code, a photo in the February 1937 The Yarn Carrier shows the number of threads and the gauge of the stocking clearly knitted into the welt. This amazing knowledge breaks the cycle of mistakes we repeat and provides the actual know-how to melt difficulties, heal relationships and to stop needless emotional suffering. Most of these processes required highly specialized skills. Like so many companies or institutions in Wyomissing, Arrow grew out of the original Wyomissing Industries. At its peak, from the 1920s through the 1950s, the Berkshire Knitting Mills made more womens full-fashioned stockings than any other plant in the world. Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors. Today, as I walk through the large buildings that once housed the Wyomissing Industries, I am acutely aware that America has become a nation of consumers.

- Etsy Bridesmaid Earrings

- Giorgio Armani Eau De Parfum

- Zara Perfume Amber Fusion

- Festo Quick Connectors

- Full Spectrum Infrared Sauna Dangers

- How To Connect Plantronics Cs540 Headset To Computer

- Black Linen Shirt Women's

- Porch Swing Chain Kit Lowe's

- Chicago Consumer Private Equity

- Luster Products Owner

- Kask Helmet Accessories

- Men's Wearhouse Calvin Klein Blue Suit

- Privacy Screen Planter Plans

- Nike Blazer Mid Jumbo On Feet

- Brita Filter Replacement Target

- Thayers Witch Hazel Aloe Vera

- Dirt Devil 08100 Belt