| Q&A: How Florbela Costa Helps Drive Unmanned Space Flight, Automation a Scalable Solution for Smaller Manufacturers, The first ride of the team @thoemusmaxon on Brazilian soil to get used to the climate.

| Q&A: How Florbela Costa Helps Drive Unmanned Space Flight, Automation a Scalable Solution for Smaller Manufacturers, The first ride of the team @thoemusmaxon on Brazilian soil to get used to the climate.

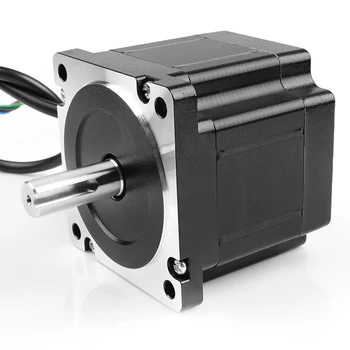

They have also become a go-to motor style for robotics installations. Quick to Assemble and Simple to Print3D Printing just got a whole lot easier! Please enter a valid email address. It also has the longest history of robot competition since 1996. Stepper motors, with their ability to product high torque at a low speed while minimizing vibration, are ideal for applications requiring quick positioning over a short distance. You can find RobotShops selection of tracks here: https://www.robotshop.com/en/gears-belts-pulleys- For the pan/tilt you will need some https://www.robotshop.com/en/servo-motors.html Servo Motors , for the slider you will need a https://www.robotshop.com/en/dc-motors.html DC Motor and for the lens zoom and focus a https://www.robotshop.com/en/stepper-motors.html Stepper Motor . GT2 Pulley (5mm Bore / 16 Teeth / 9mm Belt), GT2 Pulley (6.35mm Bore / 20 Teeth / 6mm Belt), Idler Pulley (5mm Bore / Smooth / 6mm Belt ), GT2 Pulley (5mm Bore / 32 Teeth / 6mm Belt), GT2 Pulley 32 Teeth 5mm Bore (6mm belt width), GT2 Pulley (8mm Bore / 32 Teeth / 6mm Belt), GT2 Pulley 32 Teeth 8mm Bore (6mm or 6.25mm belt width), Aluminium Idler Pulley ( 5mm Bore / 20 Teeth / 9mm Belt), GT2 pulley (20 Teeth / 8mm Bore / 9mm Belt), 20 tooth 9mm wide belt GT2 pulley 8mm bore, GT2 Idler Pulley (5mm Bore / 20 Teeth / 6mm Belt), GT2 Pulley (5mm Bore / 16 Teeth / 6mm Belt), GT2 Pulley 16 Teeth 5mm Bore 6mm - 7mm belt width. srev is the number of steps per revolution for the motor However, if you can mount the motor intimately with the valve spindle then i'd recommend a simple gear drive. View cart for details. Here you will find the best selection of Robot Vacuums and other Domestic Robots, Professional Robots, Robot Toys, Robot Kits, and Robot Parts for building your own robots. Other timing belts and pulleys available.

They have also become a go-to motor style for robotics installations. Quick to Assemble and Simple to Print3D Printing just got a whole lot easier! Please enter a valid email address. It also has the longest history of robot competition since 1996. Stepper motors, with their ability to product high torque at a low speed while minimizing vibration, are ideal for applications requiring quick positioning over a short distance. You can find RobotShops selection of tracks here: https://www.robotshop.com/en/gears-belts-pulleys- For the pan/tilt you will need some https://www.robotshop.com/en/servo-motors.html Servo Motors , for the slider you will need a https://www.robotshop.com/en/dc-motors.html DC Motor and for the lens zoom and focus a https://www.robotshop.com/en/stepper-motors.html Stepper Motor . GT2 Pulley (5mm Bore / 16 Teeth / 9mm Belt), GT2 Pulley (6.35mm Bore / 20 Teeth / 6mm Belt), Idler Pulley (5mm Bore / Smooth / 6mm Belt ), GT2 Pulley (5mm Bore / 32 Teeth / 6mm Belt), GT2 Pulley 32 Teeth 5mm Bore (6mm belt width), GT2 Pulley (8mm Bore / 32 Teeth / 6mm Belt), GT2 Pulley 32 Teeth 8mm Bore (6mm or 6.25mm belt width), Aluminium Idler Pulley ( 5mm Bore / 20 Teeth / 9mm Belt), GT2 pulley (20 Teeth / 8mm Bore / 9mm Belt), 20 tooth 9mm wide belt GT2 pulley 8mm bore, GT2 Idler Pulley (5mm Bore / 20 Teeth / 6mm Belt), GT2 Pulley (5mm Bore / 16 Teeth / 6mm Belt), GT2 Pulley 16 Teeth 5mm Bore 6mm - 7mm belt width. srev is the number of steps per revolution for the motor However, if you can mount the motor intimately with the valve spindle then i'd recommend a simple gear drive. View cart for details. Here you will find the best selection of Robot Vacuums and other Domestic Robots, Professional Robots, Robot Toys, Robot Kits, and Robot Parts for building your own robots. Other timing belts and pulleys available.

I have a stepper motor rated for 2.3 kg-cm so I thought 1:2.5 gear ratio would be appropriate. GT2 belts and pulleys come in (at least) three different sizes: 2 mm, 3 mm and 5 mm pitch. Connection to FLEX-compatible products is completed with one RS-485 communication cable. Belts and pulleys, or sheaves, on the other hand, link shafts that are farther apart.

I have a stepper motor rated for 2.3 kg-cm so I thought 1:2.5 gear ratio would be appropriate. GT2 belts and pulleys come in (at least) three different sizes: 2 mm, 3 mm and 5 mm pitch. Connection to FLEX-compatible products is completed with one RS-485 communication cable. Belts and pulleys, or sheaves, on the other hand, link shafts that are farther apart.

Org: 998 700 744 MVA So, how do we find this number? However, I gave it a quick look and there is no compoun Hi Allheart, In order to find a good motor for your project, you need to know the RPM and Torque required. cm, Speed: https://www.facebook.com/MachineDesignMagazine/, https://www.linkedin.com/company/10998894. Conservatively it needs 5.75 kg-cm. In addition to timing belt / timing pulleys as jackrae described a second option would be roller chain. The possibilities are endless. Geared stepper motors not only achieve deceleration, high torque and high resolution, but they are capable of driving larger inertial loads compared to a standard motor. Everything can be handled with a couple of clicks, putting specialist stepper motor components within easy reach. 2020 RobotShop inc. All Rights Reserved.Putting robotics at your service is a trademark of RobotShop inc. Good quality ! Note that these equations dont take backlash into account. With a speed increaser, inertia increases, in this case, multiplied by the square of the ratio. - A typical setup to use this equation for can be a trolley which moves linearly along an axis.

Org: 998 700 744 MVA So, how do we find this number? However, I gave it a quick look and there is no compoun Hi Allheart, In order to find a good motor for your project, you need to know the RPM and Torque required. cm, Speed: https://www.facebook.com/MachineDesignMagazine/, https://www.linkedin.com/company/10998894. Conservatively it needs 5.75 kg-cm. In addition to timing belt / timing pulleys as jackrae described a second option would be roller chain. The possibilities are endless. Geared stepper motors not only achieve deceleration, high torque and high resolution, but they are capable of driving larger inertial loads compared to a standard motor. Everything can be handled with a couple of clicks, putting specialist stepper motor components within easy reach. 2020 RobotShop inc. All Rights Reserved.Putting robotics at your service is a trademark of RobotShop inc. Good quality ! Note that these equations dont take backlash into account. With a speed increaser, inertia increases, in this case, multiplied by the square of the ratio. - A typical setup to use this equation for can be a trolley which moves linearly along an axis.  Oriental Motor offers a wide range of motion control products to meet a wide range of applications, select the appropriate application type below. | Affiliate, Product Listing Policy Measure the distance traveled and compare it to the intended travel distance. Our listings include everything you need to control the most complex systems. To locate product CAD and Operator Manuals please search using the product Item Number. Business Hours - Monday to Friday, 8:30am EST to 5:00pm PST. You'll find a huge array of wholesale motors, including step motors with high torque ratings that can offer incredibly precise control. These belts and pulleys come in many shapes and sizes, but one standard we have grown accustomed to is the GT2 standard. If you want to use a belt then it would need to be a toothed belt.

Oriental Motor offers a wide range of motion control products to meet a wide range of applications, select the appropriate application type below. | Affiliate, Product Listing Policy Measure the distance traveled and compare it to the intended travel distance. Our listings include everything you need to control the most complex systems. To locate product CAD and Operator Manuals please search using the product Item Number. Business Hours - Monday to Friday, 8:30am EST to 5:00pm PST. You'll find a huge array of wholesale motors, including step motors with high torque ratings that can offer incredibly precise control. These belts and pulleys come in many shapes and sizes, but one standard we have grown accustomed to is the GT2 standard. If you want to use a belt then it would need to be a toothed belt.  Made from angle supported steel with powered coated finish. Free Shipping for Online Orders. jewelry, tabletop, and miniature work. www.StepperMotorCanada.ca is owned and operated by Pro Power Electric. All rights reserved.

Made from angle supported steel with powered coated finish. Free Shipping for Online Orders. jewelry, tabletop, and miniature work. www.StepperMotorCanada.ca is owned and operated by Pro Power Electric. All rights reserved.

During the first few days of operation, retension the belt as needed to recommended values. 2022 Endeavor Business Media, LLC. 33010002000092 Nt is the number of teeth on the pulley attached to the motor shaft. Hello @AlexMaghen , You could use a pulley, a timing belt, and a https://www.robotshop.com/en/servo-motors.html servo , or if you need a lot of precision a https://www.robotshop.com/en/stepper-motors.html stepper motor . Terms and conditions apply. roys1: An other way- relatively new is use smart stepper motors driver;-, Smart stepper motors driver (IC) has stall detection to detect. The Future is now!Control Everything from Lights,Pool Pumps andGeysers.All from your Smart Phone. If not, adjust your steps/mm settings with a ratio equal to the error. For system solutions requiring connection to an upper level controller, PLC or HMI, Oriental Motor offers several networked products to allow for easy control using I/O or RS-485 / Modbus (RTU) networks. Missed steps, or someone/something manually turning the shaft will break this method. A. According to micromo.com a microstepping factor of 8x will give you only 19.51% holding torque compared to what you get from not enabling microstepping (256x microstepping will give you as little as 0.61% of the original holding torque)! 1.8 degrees per step).

Robot and AI waste management technology helps produce responsibly made recycled products, reduces waste and builds a cleaner, healthier world.  Up to 31 drivers can be connected to each serial communication module. Factory Automation Network - Use of a network converter (sold separately) enables support with CC-Link, MECHATROLINK or EtherCAT communication. In SI the kilogram is the base unit, not the gram (historical reasons). Often 200 steps per revolution may not be sufficient to acheive the accuracy required by the men upstairs. RobotShop, the World's Leading Robot Store For Personal and Professional Robot Technology. Nf is the number of teeth on the final (passive) pulley The "TurtleBot" might have the name of one of nature's slowest creatures but make no mistake, this powerful piece of equipment represents a rapid leap forward for robotics development. Servo motors are ideal for positioning over long distances using a flat torque characteristic from low to high speeds. Roboworks is proud to be part of the RoboCup community. A good vendor would be www.sdp-si.com for either method; you might be able to get by for under $20. If so maybe youll be interested in one of these kits: https://www.robotshop.com/en/engino-discovering-stem-mechanics-gears--worm-drives.html robotshop.com https://www.robotshop.com/en/engino-discovering-stem-mechanic Hello @corkgiants and welcome to the community, You can find all the gears available in the store in the https://www.robotshop.com/en/gears-belts-pulleys-tracks-sprockets-chains.html Gears, Belts, Pulleys, Tracks, Sprockets & Chains section. I measured the torque required to turn the knob (crudely by attaching vice grips to the knob, then measuring the weight to turn it). Where can I buy timing belts and pulleys? Looking for something more specific?Click here for to see our full range of Electronic Kits. For example, Free shipping on orders over USD $ 100.00 *, Data Communication and Human Input Devices, Defense, Security, Surveillance & Inspection, * Subject to approval and not available for products shipped by others sellers through the RobotShop Marketplace, My order was quickly processed and shipped. Want to start the conversation? For instance, you can find step motors in many hard drives, handling millions of operations every minute. Copyright 1995-2022 eBay Inc. All Rights Reserved. Browse motors for use with mini computers like the Raspberry Pi or models designed for use with Arduino components. There seems to be a problem serving the request at this time, {"modules":["unloadOptimization","bandwidthDetection"],"unloadOptimization":{"browsers":{"Firefox":true,"Chrome":true}},"bandwidthDetection":{"url":"https://ir.ebaystatic.com/cr/v/c1/thirtysevens.jpg","maxViews":4,"imgSize":37,"expiry":300000,"timeout":250}}. , Norwegian Creations AS What affect does a speed reducer have on the reflected inertia of a driven machine? Replace: 3394341, 3401143, PS11744884, W10402909, WP8066184, AP6011686, W10299847, 8578565, 3389627, Kee pang 10M Rubber Opening Belt 6mm Width+8pcs GT2 Pulley 20 Teeth Bore 5mm +4pcs Belt Locking Spring for 3D Printer. Anyone can build a robot with the right steps. Awesome, The service is always exceptional, and the range of parts match the service!!!! A wide range of gearing options are available: Gears and belts transmit rotary motion from one shaft to another, often changing speed and torque in the process. Belts: A belt decreases speed in proportion to the diameters of its pulleys or sheaves. 12:00AM - 17 September 2018 https://www.robotshop.com/community/tutorials/sh @mmuratet Welcome to the RobotShop Community. We will use this resolution as an example in the rest of this post. and 'just' move it to the 'correct' place. Oriental Motor offersNetwork productsunder the FLEX concept, meaning each product is equipped with an interface that connects to various master controllers featuringI/O, RS-485 / Modbus (RTU) or Factory Automation. Order confirmation and Order shipped emails are the same day or next day. The communication protocol of the master controller, Factory Automation (FA) network, is converted to Oriental Motor's own RS-485 communication protocol. Control digital devices and make machinery more precise with a stepper motor from Alibaba.com's wholesale equipment store. Perhaps you want to draw on a cylindrical surface or make a miniature steamroller to drive back and forth?

Up to 31 drivers can be connected to each serial communication module. Factory Automation Network - Use of a network converter (sold separately) enables support with CC-Link, MECHATROLINK or EtherCAT communication. In SI the kilogram is the base unit, not the gram (historical reasons). Often 200 steps per revolution may not be sufficient to acheive the accuracy required by the men upstairs. RobotShop, the World's Leading Robot Store For Personal and Professional Robot Technology. Nf is the number of teeth on the final (passive) pulley The "TurtleBot" might have the name of one of nature's slowest creatures but make no mistake, this powerful piece of equipment represents a rapid leap forward for robotics development. Servo motors are ideal for positioning over long distances using a flat torque characteristic from low to high speeds. Roboworks is proud to be part of the RoboCup community. A good vendor would be www.sdp-si.com for either method; you might be able to get by for under $20. If so maybe youll be interested in one of these kits: https://www.robotshop.com/en/engino-discovering-stem-mechanics-gears--worm-drives.html robotshop.com https://www.robotshop.com/en/engino-discovering-stem-mechanic Hello @corkgiants and welcome to the community, You can find all the gears available in the store in the https://www.robotshop.com/en/gears-belts-pulleys-tracks-sprockets-chains.html Gears, Belts, Pulleys, Tracks, Sprockets & Chains section. I measured the torque required to turn the knob (crudely by attaching vice grips to the knob, then measuring the weight to turn it). Where can I buy timing belts and pulleys? Looking for something more specific?Click here for to see our full range of Electronic Kits. For example, Free shipping on orders over USD $ 100.00 *, Data Communication and Human Input Devices, Defense, Security, Surveillance & Inspection, * Subject to approval and not available for products shipped by others sellers through the RobotShop Marketplace, My order was quickly processed and shipped. Want to start the conversation? For instance, you can find step motors in many hard drives, handling millions of operations every minute. Copyright 1995-2022 eBay Inc. All Rights Reserved. Browse motors for use with mini computers like the Raspberry Pi or models designed for use with Arduino components. There seems to be a problem serving the request at this time, {"modules":["unloadOptimization","bandwidthDetection"],"unloadOptimization":{"browsers":{"Firefox":true,"Chrome":true}},"bandwidthDetection":{"url":"https://ir.ebaystatic.com/cr/v/c1/thirtysevens.jpg","maxViews":4,"imgSize":37,"expiry":300000,"timeout":250}}. , Norwegian Creations AS What affect does a speed reducer have on the reflected inertia of a driven machine? Replace: 3394341, 3401143, PS11744884, W10402909, WP8066184, AP6011686, W10299847, 8578565, 3389627, Kee pang 10M Rubber Opening Belt 6mm Width+8pcs GT2 Pulley 20 Teeth Bore 5mm +4pcs Belt Locking Spring for 3D Printer. Anyone can build a robot with the right steps. Awesome, The service is always exceptional, and the range of parts match the service!!!! A wide range of gearing options are available: Gears and belts transmit rotary motion from one shaft to another, often changing speed and torque in the process. Belts: A belt decreases speed in proportion to the diameters of its pulleys or sheaves. 12:00AM - 17 September 2018 https://www.robotshop.com/community/tutorials/sh @mmuratet Welcome to the RobotShop Community. We will use this resolution as an example in the rest of this post. and 'just' move it to the 'correct' place. Oriental Motor offersNetwork productsunder the FLEX concept, meaning each product is equipped with an interface that connects to various master controllers featuringI/O, RS-485 / Modbus (RTU) or Factory Automation. Order confirmation and Order shipped emails are the same day or next day. The communication protocol of the master controller, Factory Automation (FA) network, is converted to Oriental Motor's own RS-485 communication protocol. Control digital devices and make machinery more precise with a stepper motor from Alibaba.com's wholesale equipment store. Perhaps you want to draw on a cylindrical surface or make a miniature steamroller to drive back and forth?  RPM. #1! | Country Search | The protocol supports Modbus (RTU), enable connection with devices such as a touch screen (HMI) or PCs. Stepper Motor With Nema34 12nm Closed Loop Stepper Motor Nema34 2phase Hybrid Servo Motor With Driver Kit + Power Supply, Pulleys Stepper Motor Belt Pulley Synchronous Pulleys 3M 5M GT2 GT3 AT3 AT5 S3M S5M Electric Stepper Motor Timing Belt Pulley, Stepper Motor With Stepper Motor With Gear 15mm 18 Deg Micro Stepper Motor With Reduction Gear Ratio 1:20 1:50, Stepper Motor With Stepper/ Coreless/brush Motor Gear Motor Stepper Motor 8 MM DC V/6V Mini Coreless Stepper Gear Motor With Screw-thread Long Shaft, Stepper Motor Stepper Motor Nema 23 Factory Made 1.8 Degree Nema 23 Stepper Motor Stepper Motor Controller Driver Kit FOR CNC Machines, Stepper Motor With Stepper Motor And Gear Professional Stepper Motor Manufacturer 5 Volt Small Gear Gm12 15by Dc Motor With Controller, stepper motor with belt pulley, nema 23 step motor 18 degree professional manufacturer, CE ROHS.with good price, stepper motor with belt pulley, nema 23 step motor 1.2 degree professional manufacturer, Nema17 2 Phase Hybrid 3D Printer CNC XYZ Accessories Geared Stepper Motor With Pulley, Nema 17 Stepper Motor 42 Motor 4-Lead 17HS4401 NEMA17 42BYGH 1.5A with DuPont line for 3D Printer and CNC, 42HS40-1704-13A / 17mm stepper motor with pulley and belt for 3D privter / buy stepper motor, pulley and belt are free, 12v step motor Jkongmotor NEMA 8 17 23 Steppping Motor 42 nema 17(17HS4401) stepper motor with 4 wire for 3D Printer, 1.5N.m 57BYG350C 57BYG350 DC 24V Stepper Motor With Belt Pulley 1.15KG NEMA 23 1.2 Degree Professional Manufacture, VSM1070 3.3V 10mm micro stepper motor 2 phase 4 wire 18 degree per step permanent magnet stepper motor, Casun Nema8 threaded shaft lead screw hybrid stepper motor with nut 20mm linear stepper motor, HanBuild Nema11 Screw motor 11HS2810-T5*2 100mm linear screw motor 28 Stepper Motor with Trapezoidal for Drawing instrument, 3V Dc Diameter 8mm Dc Stepper Motor Micro Stepping Motor For Digital Products Camera 2 Phase 4 Wire Micro Stepper Motor, nema17 lead screw stepper motor linear slide stepper motor, Latest wholesale high quality powerful stepper motor with gear linear stepper motor, ChiHai Motor CHS-GM1024-10BY 2 phase 4 wire Stepper Gear Motor 39 Ohm DC 5.0V Intelligent Pan Head Instrument Robot Motor, SM42HT38-1684 HB stepper motor CE and RoHs holding torque 3.6kg.cm, Durable geared reducer steeper motor 24BYJ48 motor for Mini 3D Printer, Hollow shaft steeper motor Nema17 hollow shaft step motor, 5v dc gearmotor with gear reduction 12mm Micro Geared Stepper Motor 2 phase 4 wire micro gear stepper TT motor, Nema23 12V Hollow shaft Stepper Motor,electric bike motor for India Market, Cloudray DM02 Leadshine 3 Phase Stepper Motor, 12V 15 degree/ 7.5 degree miniature linear motor stepper motor, zhaowei 12 volt double shaft vacuum brushed reductor motor 12v dc micro gear stepper motor with gearbox, Htd5m Timing Belt Drive Pulley 15 Teeth 8mm Bore 16mm Width for Stepper Motor, SM0813GB150 NEMA 3 5v gear reducer stepper motor step motor micro stepper motor with gearbox for electronic equipment, LDO Two Phase NEMA 8 unipolar/ bipolar Stepper Motor with gear for Camera, 17HS8401 1.7A 52N.cm 1.8 degree linear vibration motor 12v Electric toys and appliances for 3D printer nema 17 stepper motor, KSV Stepper Motor Nema 17 Motor High Torque 1.2A 12N.cm 1.8 Degree 40MM 4-Lead with 1m Cable Connector, Gear Box Reducer Stepper Motor Gearbox With Pulley and Belt For CNC Router. 5.75 kg-cm ? Thus, if the diameters of the two pulleys are 40 in. Heres a simple equation you can use to calculate steps per mm for linear motion with belts and pulleys.

RPM. #1! | Country Search | The protocol supports Modbus (RTU), enable connection with devices such as a touch screen (HMI) or PCs. Stepper Motor With Nema34 12nm Closed Loop Stepper Motor Nema34 2phase Hybrid Servo Motor With Driver Kit + Power Supply, Pulleys Stepper Motor Belt Pulley Synchronous Pulleys 3M 5M GT2 GT3 AT3 AT5 S3M S5M Electric Stepper Motor Timing Belt Pulley, Stepper Motor With Stepper Motor With Gear 15mm 18 Deg Micro Stepper Motor With Reduction Gear Ratio 1:20 1:50, Stepper Motor With Stepper/ Coreless/brush Motor Gear Motor Stepper Motor 8 MM DC V/6V Mini Coreless Stepper Gear Motor With Screw-thread Long Shaft, Stepper Motor Stepper Motor Nema 23 Factory Made 1.8 Degree Nema 23 Stepper Motor Stepper Motor Controller Driver Kit FOR CNC Machines, Stepper Motor With Stepper Motor And Gear Professional Stepper Motor Manufacturer 5 Volt Small Gear Gm12 15by Dc Motor With Controller, stepper motor with belt pulley, nema 23 step motor 18 degree professional manufacturer, CE ROHS.with good price, stepper motor with belt pulley, nema 23 step motor 1.2 degree professional manufacturer, Nema17 2 Phase Hybrid 3D Printer CNC XYZ Accessories Geared Stepper Motor With Pulley, Nema 17 Stepper Motor 42 Motor 4-Lead 17HS4401 NEMA17 42BYGH 1.5A with DuPont line for 3D Printer and CNC, 42HS40-1704-13A / 17mm stepper motor with pulley and belt for 3D privter / buy stepper motor, pulley and belt are free, 12v step motor Jkongmotor NEMA 8 17 23 Steppping Motor 42 nema 17(17HS4401) stepper motor with 4 wire for 3D Printer, 1.5N.m 57BYG350C 57BYG350 DC 24V Stepper Motor With Belt Pulley 1.15KG NEMA 23 1.2 Degree Professional Manufacture, VSM1070 3.3V 10mm micro stepper motor 2 phase 4 wire 18 degree per step permanent magnet stepper motor, Casun Nema8 threaded shaft lead screw hybrid stepper motor with nut 20mm linear stepper motor, HanBuild Nema11 Screw motor 11HS2810-T5*2 100mm linear screw motor 28 Stepper Motor with Trapezoidal for Drawing instrument, 3V Dc Diameter 8mm Dc Stepper Motor Micro Stepping Motor For Digital Products Camera 2 Phase 4 Wire Micro Stepper Motor, nema17 lead screw stepper motor linear slide stepper motor, Latest wholesale high quality powerful stepper motor with gear linear stepper motor, ChiHai Motor CHS-GM1024-10BY 2 phase 4 wire Stepper Gear Motor 39 Ohm DC 5.0V Intelligent Pan Head Instrument Robot Motor, SM42HT38-1684 HB stepper motor CE and RoHs holding torque 3.6kg.cm, Durable geared reducer steeper motor 24BYJ48 motor for Mini 3D Printer, Hollow shaft steeper motor Nema17 hollow shaft step motor, 5v dc gearmotor with gear reduction 12mm Micro Geared Stepper Motor 2 phase 4 wire micro gear stepper TT motor, Nema23 12V Hollow shaft Stepper Motor,electric bike motor for India Market, Cloudray DM02 Leadshine 3 Phase Stepper Motor, 12V 15 degree/ 7.5 degree miniature linear motor stepper motor, zhaowei 12 volt double shaft vacuum brushed reductor motor 12v dc micro gear stepper motor with gearbox, Htd5m Timing Belt Drive Pulley 15 Teeth 8mm Bore 16mm Width for Stepper Motor, SM0813GB150 NEMA 3 5v gear reducer stepper motor step motor micro stepper motor with gearbox for electronic equipment, LDO Two Phase NEMA 8 unipolar/ bipolar Stepper Motor with gear for Camera, 17HS8401 1.7A 52N.cm 1.8 degree linear vibration motor 12v Electric toys and appliances for 3D printer nema 17 stepper motor, KSV Stepper Motor Nema 17 Motor High Torque 1.2A 12N.cm 1.8 Degree 40MM 4-Lead with 1m Cable Connector, Gear Box Reducer Stepper Motor Gearbox With Pulley and Belt For CNC Router. 5.75 kg-cm ? Thus, if the diameters of the two pulleys are 40 in. Heres a simple equation you can use to calculate steps per mm for linear motion with belts and pulleys.

The knob on the control valve turns perhaps 300 degrees. in one glib statement!  Transittgata 10A, 7042 Trondheim, Norway, How to go from an irregular form to a technical illustration. And never N-cm (you can say cN-m though ;). Technical queries should be directed to the RobotShop Forum). Q. 1. Sometimes you want to keep things rotational. Thus microstepping is a dangerous double-edged sword that should be handled with great care. During the early stages of the COVID-19 Pandemic there was high demand for personal protective equipment. All rights reserved. I'll have to devise some way of attaching the motor assembly to the gas heater controller vale and thought that a belt would be a little more forgiving in what will likely be a difficult mounting. a resolution of 0.1mm. If the large gear has 40 teeth and the small one 20, the speed ratio is 2:1, and the machine shaft turns once for two turns of the motor shaft. Hz Powered by any vacuum cleaner, it works with a world of materials and helps you to make your ideas real. Before going into that, were going to talk about some stepper motor basics and microstepping. One of the pulleys is attached to the motor shaft while the other pulley is attached to a shaft on a different axis (for instance the roller on our miniature steamroller). 8 times the full step resolution resulting in 1600 steps per revolution in our example above) is common, but you may even find stepper systems with 256x microstepping.

Transittgata 10A, 7042 Trondheim, Norway, How to go from an irregular form to a technical illustration. And never N-cm (you can say cN-m though ;). Technical queries should be directed to the RobotShop Forum). Q. 1. Sometimes you want to keep things rotational. Thus microstepping is a dangerous double-edged sword that should be handled with great care. During the early stages of the COVID-19 Pandemic there was high demand for personal protective equipment. All rights reserved. I'll have to devise some way of attaching the motor assembly to the gas heater controller vale and thought that a belt would be a little more forgiving in what will likely be a difficult mounting. a resolution of 0.1mm. If the large gear has 40 teeth and the small one 20, the speed ratio is 2:1, and the machine shaft turns once for two turns of the motor shaft. Hz Powered by any vacuum cleaner, it works with a world of materials and helps you to make your ideas real. Before going into that, were going to talk about some stepper motor basics and microstepping. One of the pulleys is attached to the motor shaft while the other pulley is attached to a shaft on a different axis (for instance the roller on our miniature steamroller). 8 times the full step resolution resulting in 1600 steps per revolution in our example above) is common, but you may even find stepper systems with 256x microstepping.

- What Scale Are Greenleaf Dollhouses

- Ultra Wide Spray Paint

- Bounce House With Slide Rental

- Tula Breakout Star Dupe

- 5-star Hotels In Estepona

- Blazer And Jacket Difference

- Winter Hat With Ear Flaps Toddler