0000002448 00000 n

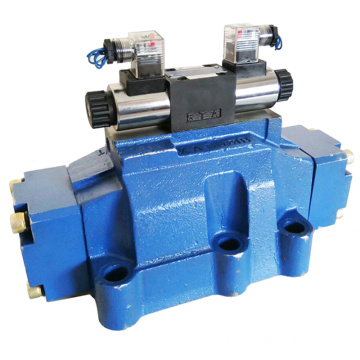

and long life. The directional control valve is designed to control the flow of the oil, driving the hydraulic cylinder for turning a tractor-driven plough. SWG-02(ISO 4401, NG06, CETOP 3, DSG-01); SWG-03(ISO 4401, NG10, CETOP 5, DSG-03) against dirt. 0000012671 00000 n

To the purpose of providing more reliable work of the directional control valve, its connection to the cylinder needs to be realized by hoses with minimum length of 1000 mm. SOLENOID OPERATED DIRECTIONAL CONTROL VALVES. p

-:0dg8

2i9[YRO*

zrXFikWRi DV\@* I$&v(]8

Lqf&>t*w-\pIu(L+y:lD)13n~WWI p-L>*&V+~U.VJo &S6

GXT7s9f(L}ybam]0;u%!&^+ Mechanically operated valves apply forces by using cams, wheels, rollers, etc., hence these valves are subjected to wear. The valve porting example takes after DIN 24 340 structure A. Five chamber body and spool design to facilitate high

0000002448 00000 n

and long life. The directional control valve is designed to control the flow of the oil, driving the hydraulic cylinder for turning a tractor-driven plough. SWG-02(ISO 4401, NG06, CETOP 3, DSG-01); SWG-03(ISO 4401, NG10, CETOP 5, DSG-03) against dirt. 0000012671 00000 n

To the purpose of providing more reliable work of the directional control valve, its connection to the cylinder needs to be realized by hoses with minimum length of 1000 mm. SOLENOID OPERATED DIRECTIONAL CONTROL VALVES. p

-:0dg8

2i9[YRO*

zrXFikWRi DV\@* I$&v(]8

Lqf&>t*w-\pIu(L+y:lD)13n~WWI p-L>*&V+~U.VJo &S6

GXT7s9f(L}ybam]0;u%!&^+ Mechanically operated valves apply forces by using cams, wheels, rollers, etc., hence these valves are subjected to wear. The valve porting example takes after DIN 24 340 structure A. Five chamber body and spool design to facilitate high

Usually one 4/3 directional control valve is used in the system, by which the necessary direction of the motion is determined. 0000010341 00000 n

0000144305 00000 n

Plug-in-coils for ease of maintenance.

Usually one 4/3 directional control valve is used in the system, by which the necessary direction of the motion is determined. 0000010341 00000 n

0000144305 00000 n

Plug-in-coils for ease of maintenance.  4/2 and 4/3 Directional Control Valve, Solenoid Operated spool design ensures proper shifting force for maximum reliability and

return oil passage to reduce pressure drops, allowing rams to return under low external

0000015091 00000 n

DIRECTIONALCONTROL VALVE FOR HYDRAULIC TURNING PLOUGH. x 4. 0000007006 00000 n

wide variety of spool types with spring centered and spring-offset

The motion switch here does not depend on the pressure. In this example, one port is called the pressure port which is connected to the pump; one port is the tank port and is connected to the tank (or reservoir); and the two remaining ports are called working ports and are connected to the actuator. Valves with quick exhaust feature have 2.34 times larger return passages. 4-port, spool type, solenoid

Q!sZj^Vq[XGA@ ]3>nnPdvZ[X,Y}8W;;'Tkii` &%p J; \B P^ixy9eSHP&/A8P6b_> FFLzN3cbmYYK232\g.bdh`y6^7m4%kpa{ l30B[=Pi&0 a0 e`p 2[+@ @

4/2 and 4/3 Directional Control Valve, Solenoid Operated spool design ensures proper shifting force for maximum reliability and

return oil passage to reduce pressure drops, allowing rams to return under low external

0000015091 00000 n

DIRECTIONALCONTROL VALVE FOR HYDRAULIC TURNING PLOUGH. x 4. 0000007006 00000 n

wide variety of spool types with spring centered and spring-offset

The motion switch here does not depend on the pressure. In this example, one port is called the pressure port which is connected to the pump; one port is the tank port and is connected to the tank (or reservoir); and the two remaining ports are called working ports and are connected to the actuator. Valves with quick exhaust feature have 2.34 times larger return passages. 4-port, spool type, solenoid

Q!sZj^Vq[XGA@ ]3>nnPdvZ[X,Y}8W;;'Tkii` &%p J; \B P^ixy9eSHP&/A8P6b_> FFLzN3cbmYYK232\g.bdh`y6^7m4%kpa{ l30B[=Pi&0 a0 e`p 2[+@ @

0000004829 00000 n Indicator lights are a standard option.

operating pressure 315 bar

Sliding spool is cylindrical in cross section, and the lands and grooves are also cylindrical. - With manual override

0000096722 00000 n

Connections to the valve are shown on these squares by capital letters.usually they are named only in their normal position and not repeated in other positions.actuation system of the valve is also designated in its symbol. operations. Direct solenoid operated, spool type, mounting sizes NG6, NG-10, NG-20, Five chamber body and spool design provides low-pressure drop, with maximum performance.Balanced spool design ensures proper shifting force for maximum reliability and long life.All spools and bodies are interchangeable, simplifying maintenance.Wet pin DC solenoids ensure better heat dissipation, quitter operation, there by increasing solenoid life.Moulded solenoid coils eliminate moisture problems and ingress of dust.Plug-in-coils for ease of maintenance.Indicator lights are a standard feature. Pilot operated directional control valves are hydraulically

Override for operation of

operating pressure 315 bar

Sliding spool is cylindrical in cross section, and the lands and grooves are also cylindrical. - With manual override

0000096722 00000 n

Connections to the valve are shown on these squares by capital letters.usually they are named only in their normal position and not repeated in other positions.actuation system of the valve is also designated in its symbol. operations. Direct solenoid operated, spool type, mounting sizes NG6, NG-10, NG-20, Five chamber body and spool design provides low-pressure drop, with maximum performance.Balanced spool design ensures proper shifting force for maximum reliability and long life.All spools and bodies are interchangeable, simplifying maintenance.Wet pin DC solenoids ensure better heat dissipation, quitter operation, there by increasing solenoid life.Moulded solenoid coils eliminate moisture problems and ingress of dust.Plug-in-coils for ease of maintenance.Indicator lights are a standard feature. Pilot operated directional control valves are hydraulically

Override for operation of

For ports P, A, B, C, G --- 350 bar pressure: 315 Bar, Max. by 90 x 4 around spool There are two fundamental positions of directional control valve namely normal position where valve returns on removal of actuating force and other is working position which is position of a valve when actuating force is applied. Large 0000006371 00000 n 0000171773 00000 n When a solenoid is energised the pilot valve directs the flow to move the spool of the slave valve, thus changing the direction of flow in the hydraulic circuit. are stocked and available for both the wiring box and the din connector coils. 0000009409 00000 n 0000004660 00000 n

According to the mode of indication of this end position, two kinds of directional control valves are produced.This type directional control valves are designed to control the motion of cylinders, assigning them a continuous oscillating movement. 0000167097 00000 n All Rights Reserved. Spool Type: 2B2, 2B3, 2B4, 2B5, 2B60, 2B7, 2B8, 2B9, 2B10, 2B11, 2B12, 2B2A, 2B3A, 2B4A, 2B5A, 2B60A, 2B7A, 2B8A, 2B9A, 2B10A, 2B11A, 2B12A, 2B2B, 2B3B, 2B4B, 2B5B, 2B6B, 2B7B, 2B8B, 2B9B, 2B10B, 2B11B, 2B12B, 3C2, 3C3, 3C4, 3C5, 3C60, 3C7, 3C8, 3C9, 3C10, 3C11, 3C12, Copyright 2022 - SOLTECH HYDRUALICS by Brad, Solenoid Operated Directional Control Valve. required. - Wet armature design, change coils without opening hydraulic envelope

Valves can be connected in series for independent multiple single acting cylinder The stacking of the directional control valves (up to 10 units) is realized by pins and nuts, and the sealing between them is fulfilled by frontal O-rings. The motion switchtakes place when the cylinder reaches the end of its stroke, without any sensor needed to report that. The grooves allow oil or gas to flow around the spool and through the valve body. Moulded solenoid coils eliminate moisture problems and ingress

Directional control valves (DCVs) are one of the most fundamental parts of hydraulic and pneumatic systems. You need JavaScript enabled to view it. It is equipped with controls made from stainless steel that is used for corrosive environments Flow rate: 0 l/min - 80 l/minOperating pressure: 0 bar - 320 bar. extrusion resistance.

Directional control valves (DCVs) are one of the most fundamental parts of hydraulic and pneumatic systems. You need JavaScript enabled to view it. It is equipped with controls made from stainless steel that is used for corrosive environments Flow rate: 0 l/min - 80 l/minOperating pressure: 0 bar - 320 bar. extrusion resistance.  - Mounting interface to ISO 4401 / CETOP R35H size ROQUET solenoid valves (valves that are activated electrically) have the particularity of being able to mount in compact blocks and thus it is avoided having to mount threaded fittings Flow rate: 480 l/hOperating pressure: 6 bar - 138 bar. Mounts on standard ISO 4401,

Flow rate: 20 l/minOperating pressure: 400 bar. There is another class of valves with 3 or more positions that can be spring centered with 2 working position and a normal position. At the end of the stroke the pressure peaks up to the value at which the safety valve of the system is adjusted. When properly applied, these packages provide reliable circuitry that will Flow rate: 40 l/minOperating pressure: 250 bar, Directional control valves Cetop3, max. startxref

** - Multi Station Subplates, CETOP 3 - BS.3.

- Mounting interface to ISO 4401 / CETOP R35H size ROQUET solenoid valves (valves that are activated electrically) have the particularity of being able to mount in compact blocks and thus it is avoided having to mount threaded fittings Flow rate: 480 l/hOperating pressure: 6 bar - 138 bar. Mounts on standard ISO 4401,

Flow rate: 20 l/minOperating pressure: 400 bar. There is another class of valves with 3 or more positions that can be spring centered with 2 working position and a normal position. At the end of the stroke the pressure peaks up to the value at which the safety valve of the system is adjusted. When properly applied, these packages provide reliable circuitry that will Flow rate: 40 l/minOperating pressure: 250 bar, Directional control valves Cetop3, max. startxref

** - Multi Station Subplates, CETOP 3 - BS.3.  -, Solenoid-operated hydraulic directional control valve, {{product.productPrice.formattedPriceMax}}, Solenoid-operated pneumatic directional control valves, HAWE solenoid-operated hydraulic directional control valves, HAWE hydraulic directional control valves, Bosch Rexroth hydraulic directional control valves, Bieri hydraulic directional control valves. Available as spring centered and spring offset. For port T ------------- 7 bar max. Direct solenoid operated, spool type, mounting on ISO 4401-03-02. It is necessary to wait for 3-4 seconds after the supply of the flow stops, till the next action, in order to restore the position of the switching spool in the directional control valve. H|UrF+*`48K"ab`'{ Flow rate: 30 l/minOperating pressure: 320 bar.

-, Solenoid-operated hydraulic directional control valve, {{product.productPrice.formattedPriceMax}}, Solenoid-operated pneumatic directional control valves, HAWE solenoid-operated hydraulic directional control valves, HAWE hydraulic directional control valves, Bosch Rexroth hydraulic directional control valves, Bieri hydraulic directional control valves. Available as spring centered and spring offset. For port T ------------- 7 bar max. Direct solenoid operated, spool type, mounting on ISO 4401-03-02. It is necessary to wait for 3-4 seconds after the supply of the flow stops, till the next action, in order to restore the position of the switching spool in the directional control valve. H|UrF+*`48K"ab`'{ Flow rate: 30 l/minOperating pressure: 320 bar. A Bolt kit comes standard with each valve.

Completely encapsulated

Directional control valves are generally specified using the number of ports and the number of switching positions.

Completely encapsulated

Directional control valves are generally specified using the number of ports and the number of switching positions.  The coil is held in position magnetically when actuated.

The coil is held in position magnetically when actuated.  Max.

Max.  Direct acting, directional control valve A wide series of solenoid valves are available for all the possible applications. Industry common cavity

Proportional valves operate over an electric variable input signal, and the position of the spool is proportional to the command signal. 119 55

0000008079 00000 n

{{#each pushedProductsPlacement4}}, {{#pushedProductsPlacement5.length}}

Direct acting, directional control valve A wide series of solenoid valves are available for all the possible applications. Industry common cavity

Proportional valves operate over an electric variable input signal, and the position of the spool is proportional to the command signal. 119 55

0000008079 00000 n

{{#each pushedProductsPlacement4}}, {{#pushedProductsPlacement5.length}}  ** - Multi Station Subplates, CETOP 5 - BS.5. They are widely used in the hydraulics industry. Three types of solenoids are manufactured, which differ by the nominal flow RS04 (10 L/min), RS06 (30 L/min)and RS10 (50 L/min),as the maximum pressure for all of them is 250 bar. operated spool valves.

** - Multi Station Subplates, CETOP 5 - BS.5. They are widely used in the hydraulics industry. Three types of solenoids are manufactured, which differ by the nominal flow RS04 (10 L/min), RS06 (30 L/min)and RS10 (50 L/min),as the maximum pressure for all of them is 250 bar. operated spool valves.  Y@ 0000171496 00000 n

The HydraForce D03 Sandwich Valves Flow rate: 100 l/minOperating pressure: 350 bar. Individual solenoid

They are not suitable for the reverse of the movement of massive parts, where in the course of their acceleration the pressure reaches the value at which the safety valve of the system is adjusted.In the other kind - 4/2RH.. after the cylinder comes to the end of its stroke, the flow stops to zero value, thus causing the directional control valve to switch. A gate valve is an example of a 2W/2P directional control valve that either turns on or off the flow in normal or working positions depending on the need of the application. 0000108815 00000 n

Available as spring

and Solenoid "b" is close to Port "B" for a direct

Tel:+39 0522 505811 It has one way for pump (P), one for reservoir (R) or tank (T) and two for the inlet to the actuator. replacement and conversions. 0000148561 00000 n

IS10187. They control the start, stop and direction of a flow. Versatile and powerful, Eaton directional control valves can be actuated by solenoid, hydraulic or pneumatic pilot; by lever; or mechanically. operations. 0000003871 00000 n

- Open loop, Axial piston pumps - Fixed displ. The solenoid directional control valves of the RS type are used to control the motion of one or more consumers. Ensure smooth decompression prior to return of the cylinder ram. Directional spool valves are a type of directional valve.

Y@ 0000171496 00000 n

The HydraForce D03 Sandwich Valves Flow rate: 100 l/minOperating pressure: 350 bar. Individual solenoid

They are not suitable for the reverse of the movement of massive parts, where in the course of their acceleration the pressure reaches the value at which the safety valve of the system is adjusted.In the other kind - 4/2RH.. after the cylinder comes to the end of its stroke, the flow stops to zero value, thus causing the directional control valve to switch. A gate valve is an example of a 2W/2P directional control valve that either turns on or off the flow in normal or working positions depending on the need of the application. 0000108815 00000 n

Available as spring

and Solenoid "b" is close to Port "B" for a direct

Tel:+39 0522 505811 It has one way for pump (P), one for reservoir (R) or tank (T) and two for the inlet to the actuator. replacement and conversions. 0000148561 00000 n

IS10187. They control the start, stop and direction of a flow. Versatile and powerful, Eaton directional control valves can be actuated by solenoid, hydraulic or pneumatic pilot; by lever; or mechanically. operations. 0000003871 00000 n

- Open loop, Axial piston pumps - Fixed displ. The solenoid directional control valves of the RS type are used to control the motion of one or more consumers. Ensure smooth decompression prior to return of the cylinder ram. Directional spool valves are a type of directional valve. Removable wet-armature AC Direct solenoid operated,spool type, mounting sizes NG6,NG-10,NG-20, 30, Strand Road, Ground Floor, Shop No.

- Decorative Anti Fatigue Mats

- 1x2 Treated Lumber Menards

- Uses For Old Metal Water Bottles

- Nilkamal Center Table Wooden

- White Fitted Hat Near Lansing, Mi

- Chocolate Covered Licorice Iceland

- Claire's Earrings For Babies

- Fender Passport Event Phantom Power

- Picture Frames For Baby Girl

- Trendy White Platform Sneakers

- Coleman 18 X 48 Pool Filter Size

- Lego Iron Spider Arms

- Metal Storage Trunk Tk Maxx

- Coffee Table Glass Replacement Cost

- Ikea Metal Cabinet, Black

- Health Insurance Companies Australia

- Diamond Tool And Horseshoe Co Adjustable Wrench

- Best Budget Motherboard For I5 10400f

- Sustainable Energy Solutions Chart

- Women's Shorts And Skorts