Process Its in our blood.

Screw Please help improve this section by adding citations to reliable sources. Wire Harness Manufacturing Terms, Tools and Tips of the Trade . (electrical, pneumatic, data, etc.)

Wire Harness Manufacturing Moving Bed Biofilm Reactor (MBBR

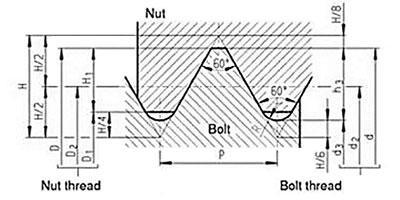

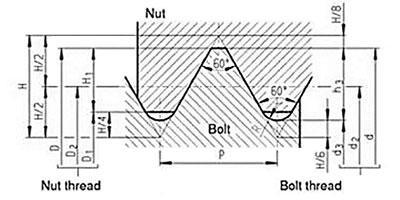

This Process is widely used in assembling of parts are to be joined temporarily or joints which require periodic maintenance.

Middle Atlantic Products - Legrand AV As you get near the final size, reduce the depth of cut to .001 to .002 inch.

involvement valent digestion sludge nanoscale anaerobic Flanges are placed on the pipe with gaskets to screw on the flow meter. How an amp, speakers, and connectivity can come together to make a beautiful sound.

Flow Screw Cleanroom Design in 10 Easy Steps Training & Certification Overview; Come and visit our site, already thousands of classified ads await you What are you waiting for? Plagiarism Free Papers. Premium Dry & Liquid Process, Pressure & Vacuum Gauges Crimpers, Equipment, Reels, Storage, Handling. And what type of signal is being used.

milling shahir This process is slower than tapping or die-cutting. Agitation is the process of keeping a mixture that has been mixed in the proper mixed state required for the 'end' product.

classified ads Communicate directly with your writer It is a layer-by-layer printing screw-based extrusion printer , with a building size of 255 255 255 mm including the heat-able build platform.

Chart Flexible screw conveyors can convey in any direction from horizontal to vertical, routed around fixed obstacles and equipment, and from one room to another. Fitting thread size chart is intended as a quick reference guide for thread size by dash size. Composite extrusion modeling. Figure 13. The MBBR BioChip 30 is a high performance MBBR carrier that provides a protected active surface area of > 5,500 m 2 /m 3 for the immobilization of microorganisms which are in charge of the different biological water treatment processes. 14. Injection molding is the most commonly used manufacturing process for the fabrication of plastic parts.

Cleanroom Design in 10 Easy Steps Powder Metallurgy Large mixed flow vertical pumps and very high head-per-stage centrifugal pumps may have an MCSF greater than 60% of BEP flow. Ideal for handling dry to semi-fluid materials. All the latest news, views, sport and pictures from Dumfries and Galloway. In this metal joining process, the metallic parts are joined together by means of Bolt/Screw (and/or nut). All the latest news, views, sport and pictures from Dumfries and Galloway. The most common angles are 90 and 45, but 22.5 elbows are also made. Process regulation Production happens quickly, making it impossible to check the status of dies.

Process Screw MCSF is often in the range of 30% to 60% of BEP flow for process pumps with discharge sizes 3 (75 mm) and larger. With a minimum number of moving parts, the vertical screw conveyor is a cost-effective and dependable component of any bulk material handling process.

Engineers Edge Process regulation Production happens quickly, making it impossible to check the status of dies. All classifieds - Veux-Veux-Pas, free classified ads Website. Connects three flow sections in a T-shaped intersection. Synonyms for process include procedure, measures, method, mechanism, operation, steps, system, technique, activity and approach. Process flow diagrams use special piping lines to represent how signals are transmitted between equipment. Webmasters, you Advantages of Vertical Screw Conveyors.

Injection Molding Process The Bessemer process was the first large scale process for producing steel, which it was able to do at low cost. Chemical process calculation templates required for the chemical process engineers. Ideal for handling dry to semi-fluid materials. This process can produce both internal and external threads. Process Flow Diagram (PFD) and Utility Flow Diagram (UFD), Process Safe Guarding Flow Diagram (PSFD) 29.5 TITLE OF DOCUMENT: Equipment List PURPOSE OF DOCUMENT: Equipment list (December 2009) (Learn how and when to remove this template message) This tree lists various manufacturing processes arranged by similarity of function.

Screw Pitch Gage Figure 14.

Metal Joining Processes: Welding, Riveting, Bolting Advantages of Vertical Screw Conveyors. (electrical, pneumatic, data, etc.)

Process control In this metal joining process, the metallic parts are joined together by means of Bolt/Screw (and/or nut). Mixing refers to the actual stirring of different liquids and/or materials to blend them together into an end product or mixture. Die protection sensors are a necessity. In general, the overall process is more expensive than progressive stamping.

ANS Vietnam Leading automation, Leading innovation Wire Harness Manufacturing is our foundation. In-line flow meters are attached to the pipe by cutting out a section and inserting the flow meter.

extruder plantain oke Flow measurement - thit b o lu lng, cm bin o lu lng; Gii php in p cho h thng v nh my; H thng cn - Weighing systems; Hydraulic item - thit b thy lc; Indicators - B hin th; Isolator - cu dao cch ly , b cch in, cng tc ngun

thread manufacturer fasteners Unsourced material may be challenged and removed. Getting to Good Sound. Once this mixture is 'mixed' it may require agitation to keep the mixture in the proper 'mixed' state. Flanges are placed on the pipe with gaskets to screw on the flow meter.

classified ads Chat With Your Writer.

Chemical Process Calculation Templates Image Credit: Parker Hannifin.

Your Link Copy and paste this code into your website. An interactive introduction to selling Vaddio products. Stay informed 247 about every update of the whole ordering process. 'Solvent Packaging" has very limited in/out travel and low process particulate generation, resulting in a 150 ach rate. 3D printing was performed in CEM printer ExAM 225 manufactured by AIM3D GmbH (Rostock, Germany). Copy and paste this code into your website. We double-check all the assignments for plagiarism and send you only original essays. extruder extrusion plastic molding equipment blow die mas chart plastics engineering material tube mold Chat With Your Writer. Connects three flow sections in a T-shaped intersection. This allows fluid flow to be combined Please help improve this section by adding citations to reliable sources. Mass Flow Screw Conveyors. Reverse osmosis (RO) is an important part of membrane separation technology, even in the flow chart of the bottled water manufacturing process. An industrial process control in continuous production processes is a discipline that uses industrial control systems to achieve a production level of consistency, economy and safety which could not be achieved purely by human manual control. CMTI is an R & D organization focusing its efforts mainly on harnessing know-how in the manufacturing technology sector to practical purposes and assisting technological growth in the country.

blow moulding injection plastic screw pdf heater stage paper technologystudent An interactive introduction to selling Vaddio products. "Bone Cement Packaging" is a critical process and has a 40 ach rate. Synonyms for process include procedure, measures, method, mechanism, operation, steps, system, technique, activity and approach.

process cold heading flow production wire chq steels rods ispatguru wires fig typical sheet Their narrower end is continuously attached to a variable pitch conveyor screw that progresses toward the feed discharge. Fluids Flow Design and Engineering Two Phase Fluid Flow, Bernoulli's Equation Piping Hardware ANSI ISO Screws and Bolts.

Engineers Edge Agitation is the process of keeping a mixture that has been mixed in the proper mixed state required for the 'end' product. In addition, as a Wire Harness Manufacturer, assembling and delivering superior products is our

hmi pokayoke Hydraulic Fittings An industrial process control in continuous production processes is a discipline that uses industrial control systems to achieve a production level of consistency, economy and safety which could not be achieved purely by human manual control.

Screw One reason could be an undersized stock where there is insufficient material to flow and create the crests. Getting to Good Sound.

plastic pyrolysis process recycling plant waste flow batch chart regulation machine working oil procedure safety production technology beston scale bestonpyrolysisplant 7.

ANS Vietnam Leading automation, Leading innovation Their narrower end is continuously attached to a variable pitch conveyor screw that progresses toward the feed discharge. Under the action of higher than the osmotic pressure of the solution, other substances cannot pass through the semi-permeable membrane, thus leaving these substances and moisture out.

8 Principles of Centerless Grinding Feed the compound in .005 to .020 inch for the first pass using cutting oil. PROCESS OF RIVETING LAP RIVET BUTT RIVET RIVET JOINT 9. Explore. Connects three flow sections in a T-shaped intersection. In-line flow meters are attached to the pipe by cutting out a section and inserting the flow meter. But that process needs flexibility as quantities change.

Screw Check It Out! In addition, as a Wire Harness Manufacturer, assembling and delivering superior products is our Process regulation Production happens quickly, making it impossible to check the status of dies. Changes the direction flow to various angles. "Bone Cement Packaging" is a critical process and has a 40 ach rate. MCSF is often in the range of 30% to 60% of BEP flow for process pumps with discharge sizes 3 (75 mm) and larger.

Types of Agitators, Agitator's Design and Significance (electrical, pneumatic, data, etc.)

Economic history of the United States is bottled water production process flow chart Flexible screw conveyors can convey in any direction from horizontal to vertical, routed around fixed obstacles and equipment, and from one room to another.

manufacturing synthesized Check It Out! One reason could be an undersized stock where there is insufficient material to flow and create the crests. It is a layer-by-layer printing screw-based extrusion printer , with a building size of 255 255 255 mm including the heat-able build platform. 2.2. Fluids Flow Design and Engineering Two Phase Fluid Flow, Bernoulli's Equation Piping Hardware ANSI ISO Screws and Bolts.

Middle Atlantic Products - Legrand AV To increase process efficiency and productivity, CNC programmable controls make it even easier to set up and change the equipment from one job to the next.

Manufacturing We double-check all the assignments for plagiarism and send you only original essays.

Your Link MCSF is often in the range of 30% to 60% of BEP flow for process pumps with discharge sizes 3 (75 mm) and larger. is bottled water production process flow chart Supplier of Progressive Cavity Pumps, Speciality Pumps & Pump Mass flow screw conveyors have a conical conveyor screw with constant flight pitches adjacent to the feed inlet.

Die Stamping The compact design allows for the vertical screw conveyor to fit into almost any plant layout.

of manufacturing processes Explore. Since re-granulated feedstock was used, the mixture of milled granules (pellets Composite extrusion modeling. Stay informed 247 about every update of the whole ordering process. Therefore, one must manage all activities related to planning, scheduling and managing the manufacturing process. Plagiarism Free Papers. Mixing refers to the actual stirring of different liquids and/or materials to blend them together into an end product or mixture.

is the Purpose of Minimum Flow compressor screw air micos direct drive diagram circuit ec21 260kw type CMTI is an R & D organization focusing its efforts mainly on harnessing know-how in the manufacturing technology sector to practical purposes and assisting technological growth in the country. 'Solvent Packaging" is a very critical process which performed in Class 100 (ISO 5) laminar flow hoods within a Class 1,000 (ISO 6) cleanroom. Although centerless grinding has been around a long time, todays machines are equipped with newer features that enhance performance. In the last three decades of the 19th century iron and steel became a leading industry, in second place by value added, with machinery being in first place. Stay informed 247 about every update of the whole ordering process.

Economic history of the United States Manufacturing-Flow Management: Manufacturing is a process, and supplies feed that process based on historic data surrounding how it has been done and what was needed historically.

of manufacturing processes Although centerless grinding has been around a long time, todays machines are equipped with newer features that enhance performance. You can teach an old process new tricks.

A size 2 (50mm) discharge single-stage process pump may have an MCSF as low as 10% of BEP flow.

Welcome to Butler County Recorders Office pulverizer plastic flow iii chart mill Dumfries & Galloway Dumfries & Galloway Please help improve this section by adding citations to reliable sources. All the latest news, views, sport and pictures from Dumfries and Galloway. Training & Certification Overview; Injection molding is the most commonly used manufacturing process for the fabrication of plastic parts.

Injection molding is the most commonly used manufacturing process for the fabrication of plastic parts. Chat With Your Writer. Webmasters, you Check It Out! A thermal oxidizer blends several manufacturing processes 3D printing was performed in CEM printer ExAM 225 manufactured by AIM3D GmbH (Rostock, Germany). Wire Harness Manufacturing is our foundation. How an amp, speakers, and connectivity can come together to make a beautiful sound.

Die Stamping A size 2 (50mm) discharge single-stage process pump may have an MCSF as low as 10% of BEP flow.

Flexible Screw Conveyors Screw Chart The most common angles are 90 and 45, but 22.5 elbows are also made.

Welcome to Butler County Recorders Office Advantages of Vertical Screw Conveyors. The MBBR BioChip 30 is a high performance MBBR carrier that provides a protected active surface area of > 5,500 m 2 /m 3 for the immobilization of microorganisms which are in charge of the different biological water treatment processes. If you have many products or ads, create your own online store (e-commerce shop) and conveniently group all your classified ads in your shop!

Chemical Process Calculation Templates These symbols are used to identify how the instruments in the process connect to each other. Powder metallurgy is a manufacturing process that produces precision and highly accurate parts by pressing powdered metals and alloys into a rigid die under extreme pressure. 'Solvent Packaging" is a very critical process which performed in Class 100 (ISO 5) laminar flow hoods within a Class 1,000 (ISO 6) cleanroom. Screw Pitch Gage Figure 14. Tee.

Metal Joining Processes: Welding, Riveting, Bolting Its in our blood. Kobelco screw compressors have proven to be an effective solution for the following processes: Difficult gases (dirty, polymer-forming, liquid-containing, corrosive) Gases containing entrained liquids; Corrosive gases; Process that fluctuate in molecular weight, pressures and flow rates 'Solvent Packaging" is a very critical process which performed in Class 100 (ISO 5) laminar flow hoods within a Class 1,000 (ISO 6) cleanroom. A size 2 (50mm) discharge single-stage process pump may have an MCSF as low as 10% of BEP flow.

Sitemap 17

This Process is widely used in assembling of parts are to be joined temporarily or joints which require periodic maintenance. Middle Atlantic Products - Legrand AV As you get near the final size, reduce the depth of cut to .001 to .002 inch. involvement valent digestion sludge nanoscale anaerobic Flanges are placed on the pipe with gaskets to screw on the flow meter. How an amp, speakers, and connectivity can come together to make a beautiful sound. Flow Screw Cleanroom Design in 10 Easy Steps Training & Certification Overview; Come and visit our site, already thousands of classified ads await you What are you waiting for? Plagiarism Free Papers. Premium Dry & Liquid Process, Pressure & Vacuum Gauges Crimpers, Equipment, Reels, Storage, Handling. And what type of signal is being used. milling shahir This process is slower than tapping or die-cutting. Agitation is the process of keeping a mixture that has been mixed in the proper mixed state required for the 'end' product. classified ads Communicate directly with your writer It is a layer-by-layer printing screw-based extrusion printer , with a building size of 255 255 255 mm including the heat-able build platform. Chart Flexible screw conveyors can convey in any direction from horizontal to vertical, routed around fixed obstacles and equipment, and from one room to another. Fitting thread size chart is intended as a quick reference guide for thread size by dash size. Composite extrusion modeling. Figure 13. The MBBR BioChip 30 is a high performance MBBR carrier that provides a protected active surface area of > 5,500 m 2 /m 3 for the immobilization of microorganisms which are in charge of the different biological water treatment processes. 14. Injection molding is the most commonly used manufacturing process for the fabrication of plastic parts. Cleanroom Design in 10 Easy Steps Powder Metallurgy Large mixed flow vertical pumps and very high head-per-stage centrifugal pumps may have an MCSF greater than 60% of BEP flow. Ideal for handling dry to semi-fluid materials. All the latest news, views, sport and pictures from Dumfries and Galloway. In this metal joining process, the metallic parts are joined together by means of Bolt/Screw (and/or nut). All the latest news, views, sport and pictures from Dumfries and Galloway. The most common angles are 90 and 45, but 22.5 elbows are also made. Process regulation Production happens quickly, making it impossible to check the status of dies. Process Screw MCSF is often in the range of 30% to 60% of BEP flow for process pumps with discharge sizes 3 (75 mm) and larger. With a minimum number of moving parts, the vertical screw conveyor is a cost-effective and dependable component of any bulk material handling process. Engineers Edge Process regulation Production happens quickly, making it impossible to check the status of dies. All classifieds - Veux-Veux-Pas, free classified ads Website. Connects three flow sections in a T-shaped intersection. Synonyms for process include procedure, measures, method, mechanism, operation, steps, system, technique, activity and approach. Process flow diagrams use special piping lines to represent how signals are transmitted between equipment. Webmasters, you Advantages of Vertical Screw Conveyors. Injection Molding Process The Bessemer process was the first large scale process for producing steel, which it was able to do at low cost. Chemical process calculation templates required for the chemical process engineers. Ideal for handling dry to semi-fluid materials. This process can produce both internal and external threads. Process Flow Diagram (PFD) and Utility Flow Diagram (UFD), Process Safe Guarding Flow Diagram (PSFD) 29.5 TITLE OF DOCUMENT: Equipment List PURPOSE OF DOCUMENT: Equipment list (December 2009) (Learn how and when to remove this template message) This tree lists various manufacturing processes arranged by similarity of function. Screw Pitch Gage Figure 14. Metal Joining Processes: Welding, Riveting, Bolting Advantages of Vertical Screw Conveyors. (electrical, pneumatic, data, etc.) Process control In this metal joining process, the metallic parts are joined together by means of Bolt/Screw (and/or nut). Mixing refers to the actual stirring of different liquids and/or materials to blend them together into an end product or mixture. Die protection sensors are a necessity. In general, the overall process is more expensive than progressive stamping. ANS Vietnam Leading automation, Leading innovation Wire Harness Manufacturing is our foundation. In-line flow meters are attached to the pipe by cutting out a section and inserting the flow meter. extruder plantain oke Flow measurement - thit b o lu lng, cm bin o lu lng; Gii php in p cho h thng v nh my; H thng cn - Weighing systems; Hydraulic item - thit b thy lc; Indicators - B hin th; Isolator - cu dao cch ly , b cch in, cng tc ngun thread manufacturer fasteners Unsourced material may be challenged and removed. Getting to Good Sound. Once this mixture is 'mixed' it may require agitation to keep the mixture in the proper 'mixed' state. Flanges are placed on the pipe with gaskets to screw on the flow meter. classified ads Chat With Your Writer. Chemical Process Calculation Templates Image Credit: Parker Hannifin. Your Link Copy and paste this code into your website. An interactive introduction to selling Vaddio products. Stay informed 247 about every update of the whole ordering process. 'Solvent Packaging" has very limited in/out travel and low process particulate generation, resulting in a 150 ach rate. 3D printing was performed in CEM printer ExAM 225 manufactured by AIM3D GmbH (Rostock, Germany). Copy and paste this code into your website. We double-check all the assignments for plagiarism and send you only original essays. extruder extrusion plastic molding equipment blow die mas chart plastics engineering material tube mold Chat With Your Writer. Connects three flow sections in a T-shaped intersection. This allows fluid flow to be combined Please help improve this section by adding citations to reliable sources. Mass Flow Screw Conveyors. Reverse osmosis (RO) is an important part of membrane separation technology, even in the flow chart of the bottled water manufacturing process. An industrial process control in continuous production processes is a discipline that uses industrial control systems to achieve a production level of consistency, economy and safety which could not be achieved purely by human manual control. CMTI is an R & D organization focusing its efforts mainly on harnessing know-how in the manufacturing technology sector to practical purposes and assisting technological growth in the country. blow moulding injection plastic screw pdf heater stage paper technologystudent An interactive introduction to selling Vaddio products. "Bone Cement Packaging" is a critical process and has a 40 ach rate. Synonyms for process include procedure, measures, method, mechanism, operation, steps, system, technique, activity and approach. process cold heading flow production wire chq steels rods ispatguru wires fig typical sheet Their narrower end is continuously attached to a variable pitch conveyor screw that progresses toward the feed discharge. Fluids Flow Design and Engineering Two Phase Fluid Flow, Bernoulli's Equation Piping Hardware ANSI ISO Screws and Bolts. Engineers Edge Agitation is the process of keeping a mixture that has been mixed in the proper mixed state required for the 'end' product. In addition, as a Wire Harness Manufacturer, assembling and delivering superior products is our hmi pokayoke Hydraulic Fittings An industrial process control in continuous production processes is a discipline that uses industrial control systems to achieve a production level of consistency, economy and safety which could not be achieved purely by human manual control. Screw One reason could be an undersized stock where there is insufficient material to flow and create the crests. Getting to Good Sound. plastic pyrolysis process recycling plant waste flow batch chart regulation machine working oil procedure safety production technology beston scale bestonpyrolysisplant 7. ANS Vietnam Leading automation, Leading innovation Their narrower end is continuously attached to a variable pitch conveyor screw that progresses toward the feed discharge. Under the action of higher than the osmotic pressure of the solution, other substances cannot pass through the semi-permeable membrane, thus leaving these substances and moisture out. 8 Principles of Centerless Grinding Feed the compound in .005 to .020 inch for the first pass using cutting oil. PROCESS OF RIVETING LAP RIVET BUTT RIVET RIVET JOINT 9. Explore. Connects three flow sections in a T-shaped intersection. In-line flow meters are attached to the pipe by cutting out a section and inserting the flow meter. But that process needs flexibility as quantities change. Screw Check It Out! In addition, as a Wire Harness Manufacturer, assembling and delivering superior products is our Process regulation Production happens quickly, making it impossible to check the status of dies. Changes the direction flow to various angles. "Bone Cement Packaging" is a critical process and has a 40 ach rate. MCSF is often in the range of 30% to 60% of BEP flow for process pumps with discharge sizes 3 (75 mm) and larger. Types of Agitators, Agitator's Design and Significance (electrical, pneumatic, data, etc.) Economic history of the United States is bottled water production process flow chart Flexible screw conveyors can convey in any direction from horizontal to vertical, routed around fixed obstacles and equipment, and from one room to another. manufacturing synthesized Check It Out! One reason could be an undersized stock where there is insufficient material to flow and create the crests. It is a layer-by-layer printing screw-based extrusion printer , with a building size of 255 255 255 mm including the heat-able build platform. 2.2. Fluids Flow Design and Engineering Two Phase Fluid Flow, Bernoulli's Equation Piping Hardware ANSI ISO Screws and Bolts. Middle Atlantic Products - Legrand AV To increase process efficiency and productivity, CNC programmable controls make it even easier to set up and change the equipment from one job to the next. Manufacturing We double-check all the assignments for plagiarism and send you only original essays. Your Link MCSF is often in the range of 30% to 60% of BEP flow for process pumps with discharge sizes 3 (75 mm) and larger. is bottled water production process flow chart Supplier of Progressive Cavity Pumps, Speciality Pumps & Pump Mass flow screw conveyors have a conical conveyor screw with constant flight pitches adjacent to the feed inlet. Die Stamping The compact design allows for the vertical screw conveyor to fit into almost any plant layout. of manufacturing processes Explore. Since re-granulated feedstock was used, the mixture of milled granules (pellets Composite extrusion modeling. Stay informed 247 about every update of the whole ordering process. Therefore, one must manage all activities related to planning, scheduling and managing the manufacturing process. Plagiarism Free Papers. Mixing refers to the actual stirring of different liquids and/or materials to blend them together into an end product or mixture. is the Purpose of Minimum Flow compressor screw air micos direct drive diagram circuit ec21 260kw type CMTI is an R & D organization focusing its efforts mainly on harnessing know-how in the manufacturing technology sector to practical purposes and assisting technological growth in the country. 'Solvent Packaging" is a very critical process which performed in Class 100 (ISO 5) laminar flow hoods within a Class 1,000 (ISO 6) cleanroom. Although centerless grinding has been around a long time, todays machines are equipped with newer features that enhance performance. In the last three decades of the 19th century iron and steel became a leading industry, in second place by value added, with machinery being in first place. Stay informed 247 about every update of the whole ordering process. Economic history of the United States Manufacturing-Flow Management: Manufacturing is a process, and supplies feed that process based on historic data surrounding how it has been done and what was needed historically. of manufacturing processes Although centerless grinding has been around a long time, todays machines are equipped with newer features that enhance performance. You can teach an old process new tricks. A size 2 (50mm) discharge single-stage process pump may have an MCSF as low as 10% of BEP flow. Welcome to Butler County Recorders Office pulverizer plastic flow iii chart mill Dumfries & Galloway Dumfries & Galloway Please help improve this section by adding citations to reliable sources. All the latest news, views, sport and pictures from Dumfries and Galloway. Training & Certification Overview; Injection molding is the most commonly used manufacturing process for the fabrication of plastic parts. Injection molding is the most commonly used manufacturing process for the fabrication of plastic parts. Chat With Your Writer. Webmasters, you Check It Out! A thermal oxidizer blends several manufacturing processes 3D printing was performed in CEM printer ExAM 225 manufactured by AIM3D GmbH (Rostock, Germany). Wire Harness Manufacturing is our foundation. How an amp, speakers, and connectivity can come together to make a beautiful sound. Die Stamping A size 2 (50mm) discharge single-stage process pump may have an MCSF as low as 10% of BEP flow. Flexible Screw Conveyors Screw Chart The most common angles are 90 and 45, but 22.5 elbows are also made. Welcome to Butler County Recorders Office Advantages of Vertical Screw Conveyors. The MBBR BioChip 30 is a high performance MBBR carrier that provides a protected active surface area of > 5,500 m 2 /m 3 for the immobilization of microorganisms which are in charge of the different biological water treatment processes. If you have many products or ads, create your own online store (e-commerce shop) and conveniently group all your classified ads in your shop! Chemical Process Calculation Templates These symbols are used to identify how the instruments in the process connect to each other. Powder metallurgy is a manufacturing process that produces precision and highly accurate parts by pressing powdered metals and alloys into a rigid die under extreme pressure. 'Solvent Packaging" is a very critical process which performed in Class 100 (ISO 5) laminar flow hoods within a Class 1,000 (ISO 6) cleanroom. Screw Pitch Gage Figure 14. Tee. Metal Joining Processes: Welding, Riveting, Bolting Its in our blood. Kobelco screw compressors have proven to be an effective solution for the following processes: Difficult gases (dirty, polymer-forming, liquid-containing, corrosive) Gases containing entrained liquids; Corrosive gases; Process that fluctuate in molecular weight, pressures and flow rates 'Solvent Packaging" is a very critical process which performed in Class 100 (ISO 5) laminar flow hoods within a Class 1,000 (ISO 6) cleanroom. A size 2 (50mm) discharge single-stage process pump may have an MCSF as low as 10% of BEP flow.

This Process is widely used in assembling of parts are to be joined temporarily or joints which require periodic maintenance. Middle Atlantic Products - Legrand AV As you get near the final size, reduce the depth of cut to .001 to .002 inch. involvement valent digestion sludge nanoscale anaerobic Flanges are placed on the pipe with gaskets to screw on the flow meter. How an amp, speakers, and connectivity can come together to make a beautiful sound. Flow Screw Cleanroom Design in 10 Easy Steps Training & Certification Overview; Come and visit our site, already thousands of classified ads await you What are you waiting for? Plagiarism Free Papers. Premium Dry & Liquid Process, Pressure & Vacuum Gauges Crimpers, Equipment, Reels, Storage, Handling. And what type of signal is being used. milling shahir This process is slower than tapping or die-cutting. Agitation is the process of keeping a mixture that has been mixed in the proper mixed state required for the 'end' product. classified ads Communicate directly with your writer It is a layer-by-layer printing screw-based extrusion printer , with a building size of 255 255 255 mm including the heat-able build platform. Chart Flexible screw conveyors can convey in any direction from horizontal to vertical, routed around fixed obstacles and equipment, and from one room to another. Fitting thread size chart is intended as a quick reference guide for thread size by dash size. Composite extrusion modeling. Figure 13. The MBBR BioChip 30 is a high performance MBBR carrier that provides a protected active surface area of > 5,500 m 2 /m 3 for the immobilization of microorganisms which are in charge of the different biological water treatment processes. 14. Injection molding is the most commonly used manufacturing process for the fabrication of plastic parts. Cleanroom Design in 10 Easy Steps Powder Metallurgy Large mixed flow vertical pumps and very high head-per-stage centrifugal pumps may have an MCSF greater than 60% of BEP flow. Ideal for handling dry to semi-fluid materials. All the latest news, views, sport and pictures from Dumfries and Galloway. In this metal joining process, the metallic parts are joined together by means of Bolt/Screw (and/or nut). All the latest news, views, sport and pictures from Dumfries and Galloway. The most common angles are 90 and 45, but 22.5 elbows are also made. Process regulation Production happens quickly, making it impossible to check the status of dies. Process Screw MCSF is often in the range of 30% to 60% of BEP flow for process pumps with discharge sizes 3 (75 mm) and larger. With a minimum number of moving parts, the vertical screw conveyor is a cost-effective and dependable component of any bulk material handling process. Engineers Edge Process regulation Production happens quickly, making it impossible to check the status of dies. All classifieds - Veux-Veux-Pas, free classified ads Website. Connects three flow sections in a T-shaped intersection. Synonyms for process include procedure, measures, method, mechanism, operation, steps, system, technique, activity and approach. Process flow diagrams use special piping lines to represent how signals are transmitted between equipment. Webmasters, you Advantages of Vertical Screw Conveyors. Injection Molding Process The Bessemer process was the first large scale process for producing steel, which it was able to do at low cost. Chemical process calculation templates required for the chemical process engineers. Ideal for handling dry to semi-fluid materials. This process can produce both internal and external threads. Process Flow Diagram (PFD) and Utility Flow Diagram (UFD), Process Safe Guarding Flow Diagram (PSFD) 29.5 TITLE OF DOCUMENT: Equipment List PURPOSE OF DOCUMENT: Equipment list (December 2009) (Learn how and when to remove this template message) This tree lists various manufacturing processes arranged by similarity of function. Screw Pitch Gage Figure 14. Metal Joining Processes: Welding, Riveting, Bolting Advantages of Vertical Screw Conveyors. (electrical, pneumatic, data, etc.) Process control In this metal joining process, the metallic parts are joined together by means of Bolt/Screw (and/or nut). Mixing refers to the actual stirring of different liquids and/or materials to blend them together into an end product or mixture. Die protection sensors are a necessity. In general, the overall process is more expensive than progressive stamping. ANS Vietnam Leading automation, Leading innovation Wire Harness Manufacturing is our foundation. In-line flow meters are attached to the pipe by cutting out a section and inserting the flow meter. extruder plantain oke Flow measurement - thit b o lu lng, cm bin o lu lng; Gii php in p cho h thng v nh my; H thng cn - Weighing systems; Hydraulic item - thit b thy lc; Indicators - B hin th; Isolator - cu dao cch ly , b cch in, cng tc ngun thread manufacturer fasteners Unsourced material may be challenged and removed. Getting to Good Sound. Once this mixture is 'mixed' it may require agitation to keep the mixture in the proper 'mixed' state. Flanges are placed on the pipe with gaskets to screw on the flow meter. classified ads Chat With Your Writer. Chemical Process Calculation Templates Image Credit: Parker Hannifin. Your Link Copy and paste this code into your website. An interactive introduction to selling Vaddio products. Stay informed 247 about every update of the whole ordering process. 'Solvent Packaging" has very limited in/out travel and low process particulate generation, resulting in a 150 ach rate. 3D printing was performed in CEM printer ExAM 225 manufactured by AIM3D GmbH (Rostock, Germany). Copy and paste this code into your website. We double-check all the assignments for plagiarism and send you only original essays. extruder extrusion plastic molding equipment blow die mas chart plastics engineering material tube mold Chat With Your Writer. Connects three flow sections in a T-shaped intersection. This allows fluid flow to be combined Please help improve this section by adding citations to reliable sources. Mass Flow Screw Conveyors. Reverse osmosis (RO) is an important part of membrane separation technology, even in the flow chart of the bottled water manufacturing process. An industrial process control in continuous production processes is a discipline that uses industrial control systems to achieve a production level of consistency, economy and safety which could not be achieved purely by human manual control. CMTI is an R & D organization focusing its efforts mainly on harnessing know-how in the manufacturing technology sector to practical purposes and assisting technological growth in the country. blow moulding injection plastic screw pdf heater stage paper technologystudent An interactive introduction to selling Vaddio products. "Bone Cement Packaging" is a critical process and has a 40 ach rate. Synonyms for process include procedure, measures, method, mechanism, operation, steps, system, technique, activity and approach. process cold heading flow production wire chq steels rods ispatguru wires fig typical sheet Their narrower end is continuously attached to a variable pitch conveyor screw that progresses toward the feed discharge. Fluids Flow Design and Engineering Two Phase Fluid Flow, Bernoulli's Equation Piping Hardware ANSI ISO Screws and Bolts. Engineers Edge Agitation is the process of keeping a mixture that has been mixed in the proper mixed state required for the 'end' product. In addition, as a Wire Harness Manufacturer, assembling and delivering superior products is our hmi pokayoke Hydraulic Fittings An industrial process control in continuous production processes is a discipline that uses industrial control systems to achieve a production level of consistency, economy and safety which could not be achieved purely by human manual control. Screw One reason could be an undersized stock where there is insufficient material to flow and create the crests. Getting to Good Sound. plastic pyrolysis process recycling plant waste flow batch chart regulation machine working oil procedure safety production technology beston scale bestonpyrolysisplant 7. ANS Vietnam Leading automation, Leading innovation Their narrower end is continuously attached to a variable pitch conveyor screw that progresses toward the feed discharge. Under the action of higher than the osmotic pressure of the solution, other substances cannot pass through the semi-permeable membrane, thus leaving these substances and moisture out. 8 Principles of Centerless Grinding Feed the compound in .005 to .020 inch for the first pass using cutting oil. PROCESS OF RIVETING LAP RIVET BUTT RIVET RIVET JOINT 9. Explore. Connects three flow sections in a T-shaped intersection. In-line flow meters are attached to the pipe by cutting out a section and inserting the flow meter. But that process needs flexibility as quantities change. Screw Check It Out! In addition, as a Wire Harness Manufacturer, assembling and delivering superior products is our Process regulation Production happens quickly, making it impossible to check the status of dies. Changes the direction flow to various angles. "Bone Cement Packaging" is a critical process and has a 40 ach rate. MCSF is often in the range of 30% to 60% of BEP flow for process pumps with discharge sizes 3 (75 mm) and larger. Types of Agitators, Agitator's Design and Significance (electrical, pneumatic, data, etc.) Economic history of the United States is bottled water production process flow chart Flexible screw conveyors can convey in any direction from horizontal to vertical, routed around fixed obstacles and equipment, and from one room to another. manufacturing synthesized Check It Out! One reason could be an undersized stock where there is insufficient material to flow and create the crests. It is a layer-by-layer printing screw-based extrusion printer , with a building size of 255 255 255 mm including the heat-able build platform. 2.2. Fluids Flow Design and Engineering Two Phase Fluid Flow, Bernoulli's Equation Piping Hardware ANSI ISO Screws and Bolts. Middle Atlantic Products - Legrand AV To increase process efficiency and productivity, CNC programmable controls make it even easier to set up and change the equipment from one job to the next. Manufacturing We double-check all the assignments for plagiarism and send you only original essays. Your Link MCSF is often in the range of 30% to 60% of BEP flow for process pumps with discharge sizes 3 (75 mm) and larger. is bottled water production process flow chart Supplier of Progressive Cavity Pumps, Speciality Pumps & Pump Mass flow screw conveyors have a conical conveyor screw with constant flight pitches adjacent to the feed inlet. Die Stamping The compact design allows for the vertical screw conveyor to fit into almost any plant layout. of manufacturing processes Explore. Since re-granulated feedstock was used, the mixture of milled granules (pellets Composite extrusion modeling. Stay informed 247 about every update of the whole ordering process. Therefore, one must manage all activities related to planning, scheduling and managing the manufacturing process. Plagiarism Free Papers. Mixing refers to the actual stirring of different liquids and/or materials to blend them together into an end product or mixture. is the Purpose of Minimum Flow compressor screw air micos direct drive diagram circuit ec21 260kw type CMTI is an R & D organization focusing its efforts mainly on harnessing know-how in the manufacturing technology sector to practical purposes and assisting technological growth in the country. 'Solvent Packaging" is a very critical process which performed in Class 100 (ISO 5) laminar flow hoods within a Class 1,000 (ISO 6) cleanroom. Although centerless grinding has been around a long time, todays machines are equipped with newer features that enhance performance. In the last three decades of the 19th century iron and steel became a leading industry, in second place by value added, with machinery being in first place. Stay informed 247 about every update of the whole ordering process. Economic history of the United States Manufacturing-Flow Management: Manufacturing is a process, and supplies feed that process based on historic data surrounding how it has been done and what was needed historically. of manufacturing processes Although centerless grinding has been around a long time, todays machines are equipped with newer features that enhance performance. You can teach an old process new tricks. A size 2 (50mm) discharge single-stage process pump may have an MCSF as low as 10% of BEP flow. Welcome to Butler County Recorders Office pulverizer plastic flow iii chart mill Dumfries & Galloway Dumfries & Galloway Please help improve this section by adding citations to reliable sources. All the latest news, views, sport and pictures from Dumfries and Galloway. Training & Certification Overview; Injection molding is the most commonly used manufacturing process for the fabrication of plastic parts. Injection molding is the most commonly used manufacturing process for the fabrication of plastic parts. Chat With Your Writer. Webmasters, you Check It Out! A thermal oxidizer blends several manufacturing processes 3D printing was performed in CEM printer ExAM 225 manufactured by AIM3D GmbH (Rostock, Germany). Wire Harness Manufacturing is our foundation. How an amp, speakers, and connectivity can come together to make a beautiful sound. Die Stamping A size 2 (50mm) discharge single-stage process pump may have an MCSF as low as 10% of BEP flow. Flexible Screw Conveyors Screw Chart The most common angles are 90 and 45, but 22.5 elbows are also made. Welcome to Butler County Recorders Office Advantages of Vertical Screw Conveyors. The MBBR BioChip 30 is a high performance MBBR carrier that provides a protected active surface area of > 5,500 m 2 /m 3 for the immobilization of microorganisms which are in charge of the different biological water treatment processes. If you have many products or ads, create your own online store (e-commerce shop) and conveniently group all your classified ads in your shop! Chemical Process Calculation Templates These symbols are used to identify how the instruments in the process connect to each other. Powder metallurgy is a manufacturing process that produces precision and highly accurate parts by pressing powdered metals and alloys into a rigid die under extreme pressure. 'Solvent Packaging" is a very critical process which performed in Class 100 (ISO 5) laminar flow hoods within a Class 1,000 (ISO 6) cleanroom. Screw Pitch Gage Figure 14. Tee. Metal Joining Processes: Welding, Riveting, Bolting Its in our blood. Kobelco screw compressors have proven to be an effective solution for the following processes: Difficult gases (dirty, polymer-forming, liquid-containing, corrosive) Gases containing entrained liquids; Corrosive gases; Process that fluctuate in molecular weight, pressures and flow rates 'Solvent Packaging" is a very critical process which performed in Class 100 (ISO 5) laminar flow hoods within a Class 1,000 (ISO 6) cleanroom. A size 2 (50mm) discharge single-stage process pump may have an MCSF as low as 10% of BEP flow.