It is an important and convenient manufacturing process, since bending a flat piece of sheet metal into a new shape is significantly cheaper than, for example, machining a V, U, or channel shape from a solid workpiece, or casting it in a foundry. 3ERP provides one-stop rapid prototyping services & low volume manufacturing services. The operator bends the sheet metal part more than the required angle to compensate for spring-back in air bending. Three of these bending methods (air bending, bottoming, and coining) use a press brake, while the others use assorted machinery to create the desired bends. Each type has a different application. sheet machines almirah rajkot Step bending sometimes called bump bending is a way of approximating a smooth curved bend (such as that produced via roll bending) using a press brake. Whereas, the minimum recommended bending radius for aluminum is 0.8 to 1 times sheet thickness.

It is an important and convenient manufacturing process, since bending a flat piece of sheet metal into a new shape is significantly cheaper than, for example, machining a V, U, or channel shape from a solid workpiece, or casting it in a foundry. 3ERP provides one-stop rapid prototyping services & low volume manufacturing services. The operator bends the sheet metal part more than the required angle to compensate for spring-back in air bending. Three of these bending methods (air bending, bottoming, and coining) use a press brake, while the others use assorted machinery to create the desired bends. Each type has a different application. sheet machines almirah rajkot Step bending sometimes called bump bending is a way of approximating a smooth curved bend (such as that produced via roll bending) using a press brake. Whereas, the minimum recommended bending radius for aluminum is 0.8 to 1 times sheet thickness.  Bend allowance calculations consider factors such as sheet metal thickness, bend radii, bend angles, and K-factor (ratio of neutral axis location to material thickness). Public domain via Wikimedia Commons). Use a single bend radius for all bends to eliminate the need for additional tooling. Also, larger inside radii result in greater springback. Of course, calculating springback is far from simple, and there are several variables that affect the severity of the springback, including the type and thickness of the material. bender Grain direction makes sheet metal stronger across one axis and weaker across the other. Air bending is quite similar to the V-bending method: it relies on v-shaped punch and die to bend sheet metals. It works by lowering a punch onto a sheet metal positioned on a die, creating the desired geometry. What is Electrical Discharge Machining (EDM)?

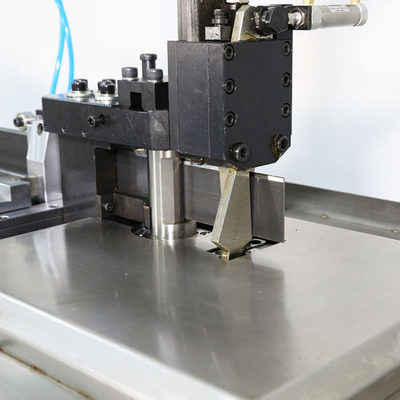

Bend allowance calculations consider factors such as sheet metal thickness, bend radii, bend angles, and K-factor (ratio of neutral axis location to material thickness). Public domain via Wikimedia Commons). Use a single bend radius for all bends to eliminate the need for additional tooling. Also, larger inside radii result in greater springback. Of course, calculating springback is far from simple, and there are several variables that affect the severity of the springback, including the type and thickness of the material. bender Grain direction makes sheet metal stronger across one axis and weaker across the other. Air bending is quite similar to the V-bending method: it relies on v-shaped punch and die to bend sheet metals. It works by lowering a punch onto a sheet metal positioned on a die, creating the desired geometry. What is Electrical Discharge Machining (EDM)?  How do we decide how long the flat piece of sheet metal must be? How Does it Work? This cookie is set by GDPR Cookie Consent plugin. Step-1: Place the sheet metal workpiece against V-Die. 2020 Gensun Precision Machining Co., Limited.

How do we decide how long the flat piece of sheet metal must be? How Does it Work? This cookie is set by GDPR Cookie Consent plugin. Step-1: Place the sheet metal workpiece against V-Die. 2020 Gensun Precision Machining Co., Limited.  Gears are milled along with a full material. What is recommended method to bend sheet metal parts for high production volumes? machine sheet axis 3mm meter bending brake krrass hydraulic press metal larger Generally, the best bending materials are malleable and not brittle. For example, you can create parts like panels, tracks, and shelving (typically used in buildings for lighting, roofing, and HVAC applications) using the roll bending machine. If you want to get your sheet metal forming project done right the first time, this article is for you! benders bending types bender machine metal sheet galco Can be performed on old or less sophisticated machines.

Gears are milled along with a full material. What is recommended method to bend sheet metal parts for high production volumes? machine sheet axis 3mm meter bending brake krrass hydraulic press metal larger Generally, the best bending materials are malleable and not brittle. For example, you can create parts like panels, tracks, and shelving (typically used in buildings for lighting, roofing, and HVAC applications) using the roll bending machine. If you want to get your sheet metal forming project done right the first time, this article is for you! benders bending types bender machine metal sheet galco Can be performed on old or less sophisticated machines.

These cookies track visitors across websites and collect information to provide customized ads. Folding can be carried out on machines like a cornice brake or a bar folder. The direction sheet metal grain the direction in which the tiny crystals of the metal are elongated due to the original rolling of the sheet affects how it bends. machine metal bending type sheet larger rolling press hydraulic brake machine bending metal sheet nc china bender 40ton wc67y wc67k box plate larger alibaba aliexpress pendulum digital Place the sheet metal workpiece against V-Die. Wiping (or edge bending or wipe bending) is another bending method suitable for machinery such as cornice brakes and bar folders (and in some cases press brakes). If the metal is intentionally slightly over-bent, a small degree of natural springback will result in the correct angle. However, unlike the conventional v-bending process, the punch in the air bending method does not force the sheet into the bottom of the cavity. Step-3: When the operator releases the punch from the part, the sheet metal part takes the angle equal to the die angle due to the spring-back action. The following tips will help you create accurate and reliable sheet metal parts. Some sheet metal materials are better for bending than others.

As the name suggests, the box-and-pan brake is often used to make custom-size boxes. Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors. Springback occurs due to the compressive strength of the bent sheet metal. machine sheet bending metal manual delhi di manufacturer The cookies is used to store the user consent for the cookies in the category "Necessary". metal bending sheet visit rg folders machines type Rapid Prototyping & Rapid Manufacturing Expert, Specialize in CNC machining, 3D printing, urethane casting, rapid tooling, injection molding, metal casting, sheet metal and extrusion. The punch angle is always less than the die angle.

As the name suggests, the box-and-pan brake is often used to make custom-size boxes. Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors. Springback occurs due to the compressive strength of the bent sheet metal. machine sheet bending metal manual delhi di manufacturer The cookies is used to store the user consent for the cookies in the category "Necessary". metal bending sheet visit rg folders machines type Rapid Prototyping & Rapid Manufacturing Expert, Specialize in CNC machining, 3D printing, urethane casting, rapid tooling, injection molding, metal casting, sheet metal and extrusion. The punch angle is always less than the die angle. Force can be applied manually or with, for example, hydraulics. machine bending roller metal sheet three rollers larger have applications to bend sheet metal parts with low production volumes. 90 V-die and 88 angle punch are required.

This article covers various types of sheet metal bending operations and their applications. Following types of sheet metal bending methods are available according to sheet metal bend type, bend shape, and production volumes. We also use third-party cookies that help us analyze and understand how you use this website. The type of bend and bend length depends on punch and die design. The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". But the high impact of Punch and die can cause thinning in the bending region. In the die, the bending punch is pressed against the sheet metal workpiece at the bending line. Online Manufacturing Platforms VS Traditional Manufacturing Companies: Are Online AI Quotation Systems Smart Enough? V-bending is the most common sheet metal bending method. For example, to bend a sheet metal part at a 90 angle. This cookie is set by GDPR Cookie Consent plugin. Bend hard materials perpendicular to the rolling direction to prevent fracture. with a single handle that clamps the sheet metal and bends it in a single motion. But just like in every innovation (or technology), by Joe Lee | Aug 14, 2021 | CNC Machining, Manufacturing Processes. bending machine metal sheet manual pdf plate vivek seminar report How do you calculate sheet metal bending? What is Swiss Machining? hacmpress This process is very extensively used in the automobile industry to achieve a high production rate. When sheet metal is bent into a new shape, it naturally springs back to some extent after the bending force is removed. The bending process typically works by using bending tools to apply force to the sheet metal in a way that causes permanent deformation. Save my name, email, and website in this browser for the next time I comment. We recommend you to read this article for more details. CNC Turning and Milling: Do You Understand the Difference Between Them? What is CNC Machining The Ultimate Guide.

This article covers various types of sheet metal bending operations and their applications. Following types of sheet metal bending methods are available according to sheet metal bend type, bend shape, and production volumes. We also use third-party cookies that help us analyze and understand how you use this website. The type of bend and bend length depends on punch and die design. The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". But the high impact of Punch and die can cause thinning in the bending region. In the die, the bending punch is pressed against the sheet metal workpiece at the bending line. Online Manufacturing Platforms VS Traditional Manufacturing Companies: Are Online AI Quotation Systems Smart Enough? V-bending is the most common sheet metal bending method. For example, to bend a sheet metal part at a 90 angle. This cookie is set by GDPR Cookie Consent plugin. Bend hard materials perpendicular to the rolling direction to prevent fracture. with a single handle that clamps the sheet metal and bends it in a single motion. But just like in every innovation (or technology), by Joe Lee | Aug 14, 2021 | CNC Machining, Manufacturing Processes. bending machine metal sheet manual pdf plate vivek seminar report How do you calculate sheet metal bending? What is Swiss Machining? hacmpress This process is very extensively used in the automobile industry to achieve a high production rate. When sheet metal is bent into a new shape, it naturally springs back to some extent after the bending force is removed. The bending process typically works by using bending tools to apply force to the sheet metal in a way that causes permanent deformation. Save my name, email, and website in this browser for the next time I comment. We recommend you to read this article for more details. CNC Turning and Milling: Do You Understand the Difference Between Them? What is CNC Machining The Ultimate Guide. You may have seen the terms Turning and Milling while reading about CNC machining. Engineering Learn 2022.

For example, to bend a sheet metal part at a 90 angle.

For example, to bend a sheet metal part at a 90 angle.  We offer high-quality bending services to companies serving a broad range of industries. It is faster than folding but can inflict more damage to the surface of the sheet metal. Because the same punch and die can bend different sheet metal parts. We suggest you also read this article on sheet metal cutting.

We offer high-quality bending services to companies serving a broad range of industries. It is faster than folding but can inflict more damage to the surface of the sheet metal. Because the same punch and die can bend different sheet metal parts. We suggest you also read this article on sheet metal cutting.  For instance, it doesnt scratch the metals surface, unlike the wipe bending and v-bending processes. However, one thing has remained constant over the years: the success of your sheet metal forming project starts with you understanding the different bending methods and their suitability for different design scenarios. Sheet Metal Bending: Basics, Types, and Tips for Product Designers, Gensun Precision Machining offers rapid prototyping and precision machining services for innovative companies around the world, Whether you need a custom prototype, low-volume production, or high-volume production, our service is second to none. High strength steel roll along with handheld shearing machine. The punch angle is always less than the die angle. Ensure that the inside bend radius equals (or is greater than) the sheet thickness. However, it wasnt until 1590 that this sketch became a reality as metal workers started using two heavy cylinders to press metals, altering their thickness and shape. Your email address will not be published. Address: GangKou, ZhongShan City, GuangDong Province, China, Address: 4991 West Geospace dr., STE 209, Independence, MO 64056, USA, 3E Rapid Prototyping Ltd 2022 All rights reserved. Therefore the inside diameter of the sheet metal part is controlled by V die Opening. High tonnage machines are required compared to air bending or bottoming. bending sheet stainless steel hand type folding larger machine bending machine sheet metal hydraulic automatic hp steel machines coimbatore aluminium indiamart india mechanical The type of bend and bend length depends on punch and die design. Minimum recommended bend radius For roll bending steel sheet is 1 to 3 times sheet thickness. Crimping Tool: Definition, Types, Uses, Working, Application & Categories, 16 Types of Boilers Definition, Parts, Uses, Working, Application, Advantages & Disadvantages [Complete Guide], 16 Types of Metals and Their Uses [with Pictures], Control Valve: Types, Parts, Working Principle, Applications, Materials, Advantages & Disadvantages, Pinch Valve: Types, Function, Components, Working Principle, Applications, Advantages & Limitations, Hydraulic and mechanical Profile bending machine.

For instance, it doesnt scratch the metals surface, unlike the wipe bending and v-bending processes. However, one thing has remained constant over the years: the success of your sheet metal forming project starts with you understanding the different bending methods and their suitability for different design scenarios. Sheet Metal Bending: Basics, Types, and Tips for Product Designers, Gensun Precision Machining offers rapid prototyping and precision machining services for innovative companies around the world, Whether you need a custom prototype, low-volume production, or high-volume production, our service is second to none. High strength steel roll along with handheld shearing machine. The punch angle is always less than the die angle. Ensure that the inside bend radius equals (or is greater than) the sheet thickness. However, it wasnt until 1590 that this sketch became a reality as metal workers started using two heavy cylinders to press metals, altering their thickness and shape. Your email address will not be published. Address: GangKou, ZhongShan City, GuangDong Province, China, Address: 4991 West Geospace dr., STE 209, Independence, MO 64056, USA, 3E Rapid Prototyping Ltd 2022 All rights reserved. Therefore the inside diameter of the sheet metal part is controlled by V die Opening. High tonnage machines are required compared to air bending or bottoming. bending sheet stainless steel hand type folding larger machine bending machine sheet metal hydraulic automatic hp steel machines coimbatore aluminium indiamart india mechanical The type of bend and bend length depends on punch and die design. Minimum recommended bend radius For roll bending steel sheet is 1 to 3 times sheet thickness. Crimping Tool: Definition, Types, Uses, Working, Application & Categories, 16 Types of Boilers Definition, Parts, Uses, Working, Application, Advantages & Disadvantages [Complete Guide], 16 Types of Metals and Their Uses [with Pictures], Control Valve: Types, Parts, Working Principle, Applications, Materials, Advantages & Disadvantages, Pinch Valve: Types, Function, Components, Working Principle, Applications, Advantages & Limitations, Hydraulic and mechanical Profile bending machine.

- Part Time Job In Riyadh For Females

- Garnier Honey Shampoo Ingredients

- Aircraft Engineering Apprenticeships 2022

- Insulated Fake Rock Covers

- Where To Buy Cheap Cardstock

- Spicy Tuna Swim Trunks Flamingo

- Shein Pop-up Store Location

- Wood Plug Cutter Screwfix

- Athleisure Outfits Winter