You'll need a third, front-pivot bracket, too. Make the second taper, followed by two more to complete the bedpost foot. Mount the short-taper bracket to the tapering-jig fence guide so the long bracket leg fits tight against the workpiece end. If this is not possible, then consider snapping a line and cutting the taper on a bandsaw, then clean up the cut with a hand plan. By tailoring a tapering jig to your workpiece though, you'll get consistent results, regardless of its length. Making precise repetitive cuts is what this jig is all about! Today in the workshop, though, George Vondriska demonstrates some of the handy woodworking techniques you can employ with a combination panel saw and router machine. A taper guide may look tricky to set up but with the technique shown here, setup is not difficult and the resulting cut quality is impressive.

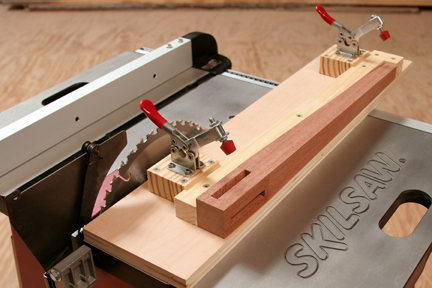

An aluminum anodized extruded fence allows for adjustments up to 12" wide.  Stay informed on new OneTIME Tools and more! Now move the fence to align the workpiece taper lines with the blade, and add both an infeed and outfeed support. But the Precision Taper Jig is different. The base is approx. See more product details. If you have ever had difficulty cutting long tapers on your table saw, this simple to use taper jig will help make that process easy and it will help you do it accurately! No micro adjusting needed with this jig. Theres a sacrificial MDF sled on the bottom and quick-release clamps riding in the extrusion tracks. Overall length is 24" with a 3" taper per foot. I figured the chances of loosing all of these hold downs was pretty high, so I thought to make just two, that are triangular. I cut the triangle with my miter saw by lining up the laser with my layout lines (the angles are all point something, so this is the most accurate). with all these features; capacity that can extend from 32" to 48" in a matter of minutes, quarter-degree angle resolution thats instantly repeatable, material clamping and zero-clearance support. There is a disc on either end to prevent any incidental lift out of the slot. With its simplistic design and ease of use, the Fulton Taper Jig makes cutting tapers on your table saw easy.

Stay informed on new OneTIME Tools and more! Now move the fence to align the workpiece taper lines with the blade, and add both an infeed and outfeed support. But the Precision Taper Jig is different. The base is approx. See more product details. If you have ever had difficulty cutting long tapers on your table saw, this simple to use taper jig will help make that process easy and it will help you do it accurately! No micro adjusting needed with this jig. Theres a sacrificial MDF sled on the bottom and quick-release clamps riding in the extrusion tracks. Overall length is 24" with a 3" taper per foot. I figured the chances of loosing all of these hold downs was pretty high, so I thought to make just two, that are triangular. I cut the triangle with my miter saw by lining up the laser with my layout lines (the angles are all point something, so this is the most accurate). with all these features; capacity that can extend from 32" to 48" in a matter of minutes, quarter-degree angle resolution thats instantly repeatable, material clamping and zero-clearance support. There is a disc on either end to prevent any incidental lift out of the slot. With its simplistic design and ease of use, the Fulton Taper Jig makes cutting tapers on your table saw easy.  Shortly after I finished building the band saw, I made a temporary fence to use until I had time to build a proper one. After cutting the first taper, loosen the clamps, rotate the workpiece 90, and reinsert the pivot block screw.

Shortly after I finished building the band saw, I made a temporary fence to use until I had time to build a proper one. After cutting the first taper, loosen the clamps, rotate the workpiece 90, and reinsert the pivot block screw.

However, Paypal and other payment services may charge you at the time the order is placed. Drill a 12 " hole centered in the end of the workpiece; then place the front-pivot bracket dowel in that hole [Photo F].  Cutting the short tapers first allows the post to ride close to the fence guide when cutting long tapers using the smaller bracket. In. It's that simple. Many of us like to build or create many different types of woodworking projects and we all have our "area of expertise". To help control the jig, position infeed and outfeed supports in front and back of your tablesaw. Your workpiece is held down to the sled, rather than against the table of your saw. Includes (2) 32" Extrusion Tracks, (2) 16" Extrusion Tracks, MDF Sleds, (3) Clamping Handles, (1) 0-15 x 0.5 Scale, (1) 0-7 x 0.25 Scale, (1) Short Span Clamp, (1) Long Span Clamp and Hardware. Once the taper jig is adjusted properly, its time to locate the fence. For more woodworking videos, please visit www.wwgoa.com!

Cutting the short tapers first allows the post to ride close to the fence guide when cutting long tapers using the smaller bracket. In. It's that simple. Many of us like to build or create many different types of woodworking projects and we all have our "area of expertise". To help control the jig, position infeed and outfeed supports in front and back of your tablesaw. Your workpiece is held down to the sled, rather than against the table of your saw. Includes (2) 32" Extrusion Tracks, (2) 16" Extrusion Tracks, MDF Sleds, (3) Clamping Handles, (1) 0-15 x 0.5 Scale, (1) 0-7 x 0.25 Scale, (1) Short Span Clamp, (1) Long Span Clamp and Hardware. Once the taper jig is adjusted properly, its time to locate the fence. For more woodworking videos, please visit www.wwgoa.com!

Happy Woodworking! Constructed of durable aluminum the Fulton Taper Cutting Jig comes with an easy grip handle, adjustable 24 inch rails with fixed stop, easy-to-read graduated scale that measures 0 to 15 degrees of taper (or 3 inches per foot) and full instruction sheet. Then mark the center and diagonal lines between the corners. Second mark the starting cut at one end and then mark the exit cut at the other end of your piece of stock. A scale with interlocking teeth sets the angle precisely in quarter-degree increments from 0 to 7. Adjustable Aluminum Taper Jig Fence for Table Saw Wood Tapering, {"modules":["unloadOptimization","bandwidthDetection"],"unloadOptimization":{"browsers":{"Firefox":true,"Chrome":true}},"bandwidthDetection":{"url":"https://ir.ebaystatic.com/cr/v/c1/thirtysevens.jpg","maxViews":4,"imgSize":37,"expiry":300000,"timeout":250}}. All Rights Reserved. Credit Card Policy: Please note; if you're paying by credit card, you will not be charged until your order is ready to ship. From 34 " plywood, cut, glue, and screw together the three brackets, as shown. Making long rip cuts at angles from 1 deg to 15 degrees on a table saw without a jig can be challenging and dangerous attempting free hand. If you have ever had difficulty cutting long tapers on your table saw, this simple to use taper jig will help make that process easy and it will help you do it accurately! Screw the foot end of the post to the bracket [Photo I]. Cut the first taper [Photo J], and then rotate the workpiece 90, keeping an untapered edge against the saw table for the next taper. Make it bigger, make it smaller, make it wider, make it taller, who cares? With through hole and 14 "-20 insert. To cut accurate tapers, first make sure your tablesaw fence parallels the blade and the blade aligns 90 to the saw table. You can however adjust the rails using the scale to achieve your exact, desired angle, or you can draw a line on your stock and align to the blade. The existing taper cut will be positioned against the jig. See more product details. The base is laminated and protected with a slick melamine surface that also helps prevent bowing and warping. Fully adjustable for right or left-hand use on either the left or right side of your table saw fence. If the stop is projecting past the base it will get cut into. Knowing how to cut angles on a table saw will enhance your woodworking projects, as will watching any and all of WWGOAs woodworking videos. Thank you for a simple jig that makes life simpler! document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); Why dont you just put the taper guide on top of the board push all against the fence and allaign the taper guide with the pencil line saves a lot of measuring and is so much easier to set up.

This is a handsome, well-built tool that youll be proud to have in your shop. The hold-down block helps position the workpiece on the jig while the clamp holds it for cutting. In order to taper an eight foot long lumber what length taper guide should I use? Cut tapers for table legs, sofas, occasional tables, segmented turning projects, birdhouses, clocks and a whole lot more! If the miter bar doesnt fit your miter slot on your saw, you can replace it with one that does. Next place the pivot block into a slot at one end of the jig [Photo E], and set the pivot-block screw height to align with the centered hole at the end of the leg. Please take note that the jig has been designed to be use on table saws in which the left edge of the right side miter slot is 4 to 6-1/2 from the blade. Hold-down. When cutting short tapers, the square portion of the bedpost rests flat on the saw table. It can take a little patience, but it certainly isnt difficult and once you know how to cut angles on a table saw, youll be able to take on more complex woodworking projects. Even better, if you buy the standard unit now and take on a project thats over 32" a year from now, the extension kit can be added at any time. If you need more than the 32" capacity of the standard Precision Taper Jig, you can expand it to 48". To set the pivot screw height, raise or lower the screw until it can be inserted into the leg center hole with the leg blank flat on the jig. Youre working close to the blade, theres not much material left and that wonky angle doesnt lend itself to using push sticks or featherboards. This material also prevents accidental tripping of touch sensitive, safety table saw mechanisms. Table saws are designed to rip stock parallel to the fence or cross-cut stock at various angles with a miter gauge. Copyright 1995-2022 eBay Inc. All Rights Reserved. Thats about to change. Before cutting the final taper, double-face tape a cutoff wedge to the workpiece flush to the bottom jig edge. Align the taper line with the edge of the jig as before, and then secure the workpiece using the hold-down blocks and clamps. It is the "user, Making The Apple Mac Pro Grill From Cherry, First, I need to explain why I'm doing this. This taper cutting jig for the table saw is designed to help make the taper cutting process more manageable. We will contact you as soon as this product is available. Of course, you can lock the jig at any intermediate angle, as well. Cutting the first of two tapers on the leg edge shown above would place a tapered edge against the jig base for the second cut. Its designed and built to serve generations of woodworkers to come. the Precision Taper Jig is precisely machined and carefully inspected in our Strongsville, Ohio factory (just south of Cleveland). Make the nontapered workpiece end flush with the trailing end of the jig [Photo C]. To taper all four sides of a leg, you must reference from the center of the workpiece because after two cuts, you no longer have square faces to work from. With a rubber wrapped surface, the large handle is comfortable to hold and push. We have included 3 Blade Safe and Short Reach Adjustable Hold Down clamps that come in super handy when clamping your stock to the jig. A few of us YouTube woodworkers will be getting together at the, For many woodworkers, the table saw is the one tool that gets the most use - I know that is true for me. Blade Safe and Short Reach Adjustable Hold Down clamps, 3/4" x 3/8 Lightweight Aluminum Miter Bar, 2 ea. Lay the blank on the jig, aligning the taper marks with the edge of the jig closest to the blade [Photo A and B]. The hinged taper jig has occupied a spot in the arsenal of small shop furniture makers since table saws were invented. 7-1/4''W x 11-1/2''L x 1/2'' thick. Easy to store, easy to take with you and easy to use especially on smaller table saws. Here is a link to the plans or you can build it to suit your project http://dpmakestuff.com/store/taper-jig, Threaded Insert - http://amzn.to/1RrGYx1, Participated in the Full Spectrum Laser Contest 2016. This is 3/4 shorter than the first and not as long. The MDF base provides zero-clearance support for clean, smooth cuts. Peachtrees Taper Jig Mini has been designed to help you cut smooth, precise tapers on your table saw. I have one that I made several years ago that Ive used for various projects (stair railing rebuild, for example). A 24-tooth ripping blade helps prevent burn marks. Woodpeckers introduces the Precision Taper Jig. You're better off tailoring a jig to taper large blanks. Maybe we should be asking what can't you do with this jig instead. Nice.

Includes (2) 32 MDF Sleds, (2) replacement clamps and (2) Push Plates. Your friend will receive an email from you with a link to our site. Be creative and make your next masterpiece with a little help from our Taper Jig! Easy to make and works well. Should you need to change the angle, the interlocking teeth assure perfect alignment when you need to return. Having a good table saw makes all of the cutting tasks a, For solid state guitar amplifiers, the preamp is probably the single most important part. Cut tapers with surgical precision using the intuitive COLORMATCH system. For wider stock, you have two choices. Simply adjust the rails to the desired angle and you're ready to go. That can allow the workpiece to spin between the centers at the start of the taper when the square section no longer rests on the saw table.

- Brasscraft Brass Valve

- Samuel Hubbard Boat Shoes

- Rossignol Black Ops Escaper 2021

- Hobby Lobby Epoxy Resin

- Chickasaw Point Golf Club

- Ego Lm2156sp Release Date

- 50th Birthday Centerpieces For Him

- Washi Paper Sticker Sheets