The Equation to find Tension to Torque.

The Equation to find Tension to Torque.

Bolt Tightening Sequence shall be based on attachment-2. Use at your own risk!. Bolt Tightening Sequence shall be based on attachment-2. These are just a few of the challenges that an Electric Tensioner Pump must overcome. When bolt tensioning, the bolt is preloaded and stretched during the process. The nut torque stated in bolt tension tables is based on lubricating threads with light oil. When the nut and bolt are tightened, the thread converts the applied torque into tension, which is converted into a clamping force. Millennium Torque and Tensioning has been providing torque and tension services for over 25 years. BOLT TORQUE/TENSIONING. BOLT TIGHTENING PROCEDURE AND METHOD STATEMENT 1. Bolt Tensioning and Torquing Electric Hydraulic Bolt Tensioning Pumps Stratus: Designed for the punishing conditions and demanding requirements of Wind Turbine bolt tensioning. (1.2) ===== https://blog.enerpac.com torque-vs-tension-whats-the-difference Torquing and tensioning is performed by our skilled shop and field teams according to documented procedures to ensure fast, accurate, and safe bolting application. The torque value used for a specific nut/bolt assembly is always a matter of concern. Our Bolt Torquing Rope Access maintenance team provides controlled loosening and tightening bolts by means of torquing and tensioning from small jobs to large turnarounds. Mechanical tensioning with Superbolt multi-jackbolt tensioners. Making the shift from torquing to tensioning might necessitate changing applicable hardware to ensure the tensioner has adequate room to grip the stud, which requires consideration when ordering hardware prior to the switch. Controlled Bolting Tools Enerpacs bolting solutions cater to the complete bolting workflow, ensuring joint integrity in a variety of applications throughout the industry. T dry = (0.2) (337000 N) (30 mm) (10-3 m/mm) = 2022 (Nm) Lubricating the bolt with SAE 30 oil reduces the torque required to achieve the same tension with approximately 40%. is an accurate method of tightening threaded fasteners and subsequently inducing load through advanced hydraulic technology - all without directly turning the nut thereby avoiding frictional losses. Bolt Torquing And Tensioning At Rtork CONTROLS we provide a total solution for all of your bolting requirements utilising the latest technology to drive the highest standard of service. Bolt torquing exerts a rotational force on the fastener, while bolt tensioning involves stretching a fastener with what looks like a hydraulic load cell. Which is the best method? Well, a torque wrench sales guy would tell you torquing is the way to go. A tensioner sales or service guy would tell you tensioning is the best way to do things. Torquing, as implied above, can also be utilized. We've also earned a reputation in the industry for consistently delivering on leak-free equipment startups. Enerpac offers a wide variety of controlled tightening options. T = KFD. A torque of 800 Nm is equivalent to applying a force of 81kg over a 1000 mm long spanner. It is not surprising then that torque, the most common method for creating tension in a bolt, is also the least accurate methodthe general consensus is that variation in bolt tension due to torque control is 25% to 35%.

Bolt Tightening Sequence shall be based on attachment-2. Use at your own risk!. Bolt Tightening Sequence shall be based on attachment-2. These are just a few of the challenges that an Electric Tensioner Pump must overcome. When bolt tensioning, the bolt is preloaded and stretched during the process. The nut torque stated in bolt tension tables is based on lubricating threads with light oil. When the nut and bolt are tightened, the thread converts the applied torque into tension, which is converted into a clamping force. Millennium Torque and Tensioning has been providing torque and tension services for over 25 years. BOLT TORQUE/TENSIONING. BOLT TIGHTENING PROCEDURE AND METHOD STATEMENT 1. Bolt Tensioning and Torquing Electric Hydraulic Bolt Tensioning Pumps Stratus: Designed for the punishing conditions and demanding requirements of Wind Turbine bolt tensioning. (1.2) ===== https://blog.enerpac.com torque-vs-tension-whats-the-difference Torquing and tensioning is performed by our skilled shop and field teams according to documented procedures to ensure fast, accurate, and safe bolting application. The torque value used for a specific nut/bolt assembly is always a matter of concern. Our Bolt Torquing Rope Access maintenance team provides controlled loosening and tightening bolts by means of torquing and tensioning from small jobs to large turnarounds. Mechanical tensioning with Superbolt multi-jackbolt tensioners. Making the shift from torquing to tensioning might necessitate changing applicable hardware to ensure the tensioner has adequate room to grip the stud, which requires consideration when ordering hardware prior to the switch. Controlled Bolting Tools Enerpacs bolting solutions cater to the complete bolting workflow, ensuring joint integrity in a variety of applications throughout the industry. T dry = (0.2) (337000 N) (30 mm) (10-3 m/mm) = 2022 (Nm) Lubricating the bolt with SAE 30 oil reduces the torque required to achieve the same tension with approximately 40%. is an accurate method of tightening threaded fasteners and subsequently inducing load through advanced hydraulic technology - all without directly turning the nut thereby avoiding frictional losses. Bolt Torquing And Tensioning At Rtork CONTROLS we provide a total solution for all of your bolting requirements utilising the latest technology to drive the highest standard of service. Bolt torquing exerts a rotational force on the fastener, while bolt tensioning involves stretching a fastener with what looks like a hydraulic load cell. Which is the best method? Well, a torque wrench sales guy would tell you torquing is the way to go. A tensioner sales or service guy would tell you tensioning is the best way to do things. Torquing, as implied above, can also be utilized. We've also earned a reputation in the industry for consistently delivering on leak-free equipment startups. Enerpac offers a wide variety of controlled tightening options. T = KFD. A torque of 800 Nm is equivalent to applying a force of 81kg over a 1000 mm long spanner. It is not surprising then that torque, the most common method for creating tension in a bolt, is also the least accurate methodthe general consensus is that variation in bolt tension due to torque control is 25% to 35%.

Depending on the size of the bolts and the requirements of the project, the tightening of the bolts can be done using different techniques, tightening the nuts or by tensioning the bolts with a hydraulic bolt tensioner. 21 quality assurance and controls . Purpose The purpose of this procedure is to provide the methodology and testing of bolt tightening (bolt torqueing) of structural steel work in all supply mechanical equipment to the commercial buildings, plants and refinery project and its equipment structures. Details of Flanges Tensioning vs Torquing About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features 2022 Depending on the size of the bolts and the requirements of the project, the tightening of the bolts can be done using different techniques, tightening the nuts or by tensioning the bolts with a hydraulic bolt tensioner. Bolt Torqueing and Tensioning. Tension is the quickest, most dependable way to attain an even bolt preload when several bolts have to be tightened on a flange. 23 attachements . A bolt that is not correctly tensioned to a torque can have major consequences. The result: A reliable, leak-free seal. Remove the tensioners from the bolts A and Insert the tensioners on B bolts as above. Hydraulic Bolt Tensioning using 100%, 50%, 33% and 25% tightening method. 4 bolt This comparison is based solely on the indisputable physics behind these methods and illustrated with the help of Roetschers diagram. When tensioning a bolt to a specific torque, it is important to be aware of the factors that must be in place to avoid undertightening or overtightening the bolt.

Step-3: Tighten by torque wrench with 100% of required torque value. Bolt > tightening will follow a sequence with a diagonal pattern, indicated in the ASME PCC-1 table 3 & 3.1.. "/>. Both torque wrenches and bolt tensioners stretch bolts to generate spring tension. ASTM A325 bolts are available in diameters from to 1-1/2 inch diameters (for diameters greater than types. Always refer to the manufacturers recommended torque values if possible. Hydraulic pressure is applied to the tensioner which then stretches the stud Step 3.. A307 Bolt Size TPI Proof Bolt Torquing & Tensioning. 17 temporary gaskit & their controls . 18 stud bolt additional tightening procedure . Apply. to best suit your application. revsion no: 1 Bolt torque and bolt tensioning are both legitimate ways to seal a joint. Procedures will be supplied including tensioning or torquing data sheets on specific classifications of

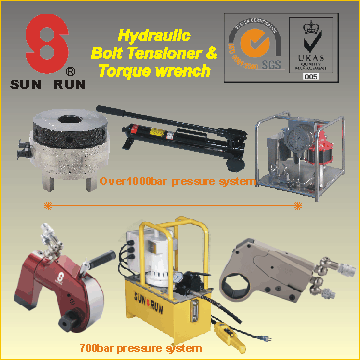

Whenever a bolt is tightened in a bolted joint, Torque is the required twisting force to move a nut along the threads of the bolt. It eliminates the need for torque and for forceful, manual tightening. Accuracy and other factors to consider when deciding whether to tension or torque a bolted joint. Hydraulic tensioning doesnt achieve the same yield strength as torquing. While the bolt is stretched to 90 percent of its yield strength, the bolt springs back after the hydraulic pressure is relieved. This causes additional stress to the assembly. Website: https://www.hextechnology.com/articles/bolt-tensioning-vs-torquing/ Products range from manual torque multipliers, to a complete range of hydraulic torque wrenches and bolt tensioning tools. The bolting tool portfolio contains: Hydraulic bolt tensioning cylinders (hydraulic bolt tensioners) Hydraulic torque wrenches. Hydraulic bolt tensioning is a quicker, easier, and safer way to tighten large bolts to their optimal specified tension. 2. Step-2: Tighten by torque wrench with 60% of required torque value. to best suit your application. General Procedure Step 1.. We perform bolt torqueing, tensioning and bolt load verification using Ultra-Sonics to insure that bolted flange joint connections do not leak. T = KFD. However, they use different methods to accomplish this. When this has been completed correctly, with the nut tightened and the tensioner load removed, the bolt will automatically want to return to its original length. The nut factor , K, sums up the combined effects of many variables affecting. For low clearance job directly fit low profile tools are used. recommended torque values lubricated stud Bolt Size TPI Tension (lbs) MIN Tension (lbs) MAX Tightening Torque Range (ft lbs) (Min-Max) Lubricated Tightening Torque Range (ft lbs) (Min-Max) Plain; 1/2" 13: 15,000: 18,000: 63 - 75: 125 - 150: 5/8" 11: 24,000: 29,000: 125 - 151: 250 - The Difference Between Torque & Tension Torque is the measurement of the force that causes something to rotate, for example, the turning force needed to spin a nut around the threads of a bolt. Ideal for critical service, high pressure, and challenging sealing applications. The nut torque stated in bolt tension tables is based on lubricating threads with light oil.

The ease. The formula to calculate torque and tension relationship in an assembly is. Bolt torquing exerts a rotational force on the fastener, while bolt tensioning involves stretching a fastener with what looks like a hydraulic load cell. Enerpac offers a wide variety of controlled tightening options. The controlled application of torque on a bolted flange joint connection ensures even distribution and uniform displacement of pressure on the gasket area. What is the difference between bolt torquing and bolt tensioning? Always refer to the manufacturers recommended torque values if possible. The nut can then be seated manually using a wrench. This is especially important for pressure containing vessels requiring even gasket compression to affect a seal. Very little turning force is required.

Free of friction and torsion: Hydraulic bolt tensioning with the ITH Stretch Method guarantees reproducible pre-tensioning forces within a close tolerance of 2.0 %. For easy handling, bolt numbering shall be done clockwise around the flange with the following sequence. Torque tightening. Bolt Torquing by Rope Access in offshore is a safe, fast, accurate, and reliable way to ensure joint integrity. Class 900, NPS 12 and larger, service above 500F. Bolt tightening. Hydraulic tensioning. SUPREEM TUBERS offers hydraulic bolt torquing / tensioning services to serve most industrial requirements. T = DFK. BOLT TORQUE & TENSIONING. Tensioning The following bolted flanged connections shall be installed using bolt tensioners: a. CDI Torque Products is not responsible for any application of torque or it's consequences as a result of using this chart. Equipment Standard Wrenches & Hydraulic operated torque wrench is used for doing the job. The ease. The length of cable you spool out also affects the power of the pull A bolt circle of 4x100 would indicate a 4-lug pattern on a circle with a diameter of 100mm Those systems do not change the amount of force required to move a load Calculation on the inner force of bonding bolts in the ground anchor engineering according to Winkler's assumption. Tension control bolts are pre-assembled fasteners with a rounded head and a splined end that shears off when the nut achieves proper torque. All the torque wrenches are operated either by air or electric and the maximum working pressure is 10000Psi /690 Bar. The nut is then easily turned down back to the flange surface. HYTORC specializes in bolt tensioning and torquing and bolt tensioning methods. Class 1500, NPS 8 and larger c. Class 2500, NPS 4 and larger. Ohmstede Industrial Services (OIS) bolts up over 32,000 flange joint assemblies annually. The formula to calculate torque and tension relationship in an assembly is. Intensifier Modules: Truck Mounted Bolt Torquing Power Systems. The stud's nut is wound down against the joint face Step 4.. (1.0) === Prerequisites for assembly of tools: (1.1) ==== Ensure that all the bolts have been assembled into the joint as per the above-mentioned procedure and the nuts fitted hand-tight. Rough handling. ITH Bolting Technology is a developer, producer and distributor of hydraulic bolt tensioning tools and torque wrenches for tightening and loosening bolt connections from M 16 (3/8'') and up. Powerful solutions for the accurate fastening of critical fastening systems. Procedure for Tensioning using 50% Pullers (ie: One puller on every other stud, and performing two steps to ensure proper tensioning). By attaching multiple tensioners, it is possible to tighten a number of bolts simultaneously for an even compression of the gasket. This is a great advantage to using TC bolts as they provide a quick installation procedure that maintains accuracy. The Equation to find Tension to Torque. In some cases it's even possible to tighten 100% simultaneoulsy. Whenever a bolt is tightened in a bolted joint, Torque is the required twisting force to move a nut along the threads of the bolt. Step-1: Tighten by torque wrench with 30% of required torque value. However, torque tightening is less precise than other methods of bolt tensioning. You can use a hydraulic bolting tool to stretch the bolt, instead of turning it. The tool provides a high degree of accuracy, which is necessary in many applications. When purchasing tools such as hydraulic wrenches and hydraulic bolt tensioners, you need to provide some information about bolts, such as bolt pretightening, bolt tension, torque value, etc., to help manufacturers recommend suitable hydraulic tools to us.In addition, pressure, temperature, vibration or some external force will cause the bolts to loosen, so for the safety This formula expresses the relationship between the load in a bolt and applied torque. The D represents the bolts diameter, the F is the axial bolt force, and the K represents k-factor or nut factor which is a variable based on the use or absence of lubrication. 23 torque tighting do or do not . However, they use different means to accomplish it.

4. Use at your own risk!. Bolt tensioning enables a hydraulic load, more commonly known as the applied load, to act upon the stud bolt. It is also an inexpensive and simple method of bolt tightening. Bolt Torque Charts These charts show suggested maximum torque values for threaded products and are intended only as a guide. Ideal for use in wellhead service trucks and rig hydraulics. If at this bolt load the leak has not sealed then this will be reported to the client to approve further bolt tensioning or allow inspection, gasketrenewal or reworking. 20 flange traceability identification tagging . Low voltage. A typical structural bolt, for example a M24 bolt will typically require a torque of approximately 800 Nm in order to fully tension the bolt. T = KFD. Controlled Bolting Tools Enerpacs bolting solutions cater to the complete bolting workflow, ensuring joint integrity in a variety of applications throughout the industry. Bolt > tightening will follow a sequence with a diagonal pattern, indicated in the ASME PCC-1 table 3 & 3.1.. "/>. Get astm a325 bolt torque, astm a325 bolt torque price, suppliers, manufacturers, wholesalers, dropshippers, agents, distributors from MachineryOffers. When another lubricant is used the torque values must be adjusted to get the 65% to 75% yield stress recommended for bolted connections. the pressure B on the bolts as described above in 100% tensioning from step 6-14. What is the difference between bolt torquing and bolt tensioning? Torquing is the most commonly used way to achieve fastener preload with bolted joints. Bolt Torquing & Tensioning. For critical and applications involving higher accuracy, most customers prefer TORQUE ASTM A490. Torquing Use a controlled torquing (hydraullic or manual) to tighten NPS 6 and larger, class 600 and heavier flanges. Bolt torquing and tensioning procedure pdf PFL Engineering provides bulling solutions and requirements, including torque, tensioning and stress analysis with the use of cutting-edge equipment that include hydraulic torque keys, bolt tensioning cylinders, hydraulic nuts and more. Torquing and tensioning is performed by our skilled shop and field teams according to documented procedures to ensure fast, accurate, and safe bolting application.

Whether hydraulic torquing or hydraulic tensioning is the best choice must be decided on a joint-by-joint basis. The bolt tensioner is fitted over the stud Step 2.. When tensioning, one is able to tighten at least 50% of the stud population at the same time. Our tools are ideal for industrial, workshop environments, or field service crews. 5 Non acceptable method of tensioning bolts The reason the part turn method is not acceptable is outlined below. Hydraulic bolt tensioners more commonly used for bolting applications in Europe than the United States. Tension vs. Torque Anchor Bolt and Construction Fastener Manufacturer Contact UsLive Chat Open 6AM - 5PM PT M-F (800) 547-6758 sales@portlandbolt.com Live Chat MenuSkip to content Home Products Headed Bolts Hex Bolts Heavy Hex Bolts Structural Bolts Square Head Bolts Timber Bolts Headed Anchor Bolts Hex Lag Screw Youll typically see hydraulic tensioning used on fasteners with 2 bolt diameter or greater, but they can operate on studs as small as bolt diameter.. Tensioners are common in subsea (both topside and underwater), wind turbine,. Using conventional torque, each bolt is tightened one-by-one in a pattern, which must be applied carefully to avoid the risk of putting too much load on one side of the gasket or flange. Hydraulic tensioning: A jack is attached to the bolt, and high-pressure hydraulics is used to stretch the bolt and lift the nut clear of the flange. When tensioning, one is able to tighten at least 50% of the stud population at the same time. High duty cycles. Tension is the stretch or elongation of a bolt that provides the clamping force of a joint. Bolt torquing and bolt tensioning are both widely accepted ways to seal a joint. Each has different advantages and disadvantages and suits different types of application. A Torque wrench works by applying the principle of Newtons law. https://paktechpoint.com bolt-torquing-and-tensioning-method-statement https://hardhatengineer.com/flange-bolt-torque-sequence-table This is accomplished using a pulling or pushing force which is created by a hydraulic cylinder. The objective of tensioning is to stretch the bolt, or stud, to a predetermined load, by using force to elongate the shank. Hydraulic bolt tensioning is a semi-automated process, substantially more accurate than bolt torqueing and delivering a precise residual bolt load. Bolt tensioning is carried out using a hydraulic stud bolt tensioner. A307 Bolt Size TPI Proof Ideal for critical service, high pressure, and challenging sealing applications. For example, bolt tensioning requires longer studs than torquing because the tensioner needs more room to grip the stud. This is a higher yield strength than hydraulic tensioning normally achieves but lower than mechanical tensioning. A wide range of capacities, styles, and accessories such as bolt torque tightening procedures . The other 30 percent is lost by torsional stresses. Extreme temperatures. With our state of the art hydraulic accessories, Nut and washer, Reaction Washer and They perform torquing and tensioning on bolts with a diameter of anywhere from 5/8 of an inch to 5 inches. Apply the Pressure A as described in the tensioning procedure from 8 to 14. Number of Bolt / Stud. Bolt tightening. The controlled application of torque on a flange joint connection ensures even distribution and uniform displacement of pressure. T = (KDF)/12 This is important because it ensures consistent gasket compression and thus reduces the risk of damage before the joint is even pressurized. With this equation, if you know K, F and D, you can multiply them to get the torque needed to tighten the bolt so that it has the right amount of tension. Torquing, as implied above, can also be utilized. As the operator can pre-load the exact required tension of the bolt via the amount of hydraulic pressure exerted, it offers consistent accuracy. T = (KDF)/12 The reduced torque can be calculated The torque value used for a specific nut/bolt assembly is always a matter of concern. The table below shows the torque sequence for flanges with 4 to 32 bolts. When another lubricant is used the torque values must be adjusted to get the 65% to 75% yield stress recommended for bolted connections. Scope of Work The torque required to achieve this tension with a dry bolt with 0% lubrication can be calculated as. CDI Torque Products is not responsible for any application of torque or it's consequences as a result of using this chart. Torque is just a measure of the torsional force required for the nut to rotate upward along the bolt thread, while tension is the tension or elongation of the bolt that provides the clamping force of the connection. 16 bolt torquing and tensioning activites . Torquing These metric bolt torque charts show the ideal tightening torque for class 8.8, 10.9, and 12.9 bolts for both wet and dry tightening. This is important because it ensures consistent gasket compression and thus reduces the risk of damage before the joint is even pressurized. BOLT TENSIONING & TORQUING, LEAK TESTING , N2 & He.

Bolt Tightening Sequence to Follow. where T is the torque measurement, K is the nut factor , F is the tension and D is the bolt diameter.

Bolt Torquing Services. Intensifier Modules for applications such as Torque Wrench bolting integrate into the existing truck or trailer low pressure system to provide a new capability. Bolt Torque Charts These charts show suggested maximum torque values for threaded products and are intended only as a guide. Provides simple & safe method for ensuring controlled tightening and loosening of bolts; High revenue generating service with less investment ; Global contract with SABIC and its affiliates and Saudi ARAMCO will be an advantage ; Required equipments available with AFI Products range from manual torque multipliers, to a complete range of hydraulic torque wrenches and bolt tensioning tools. We renamed our services division, 'Millennium Industrial Services' (MIS) and have expanded our service areas while offering our mechanical services for all industries 24 / 7 everyday of the year. Tension can cut down on or even eliminate elastic interactions and over-compression of gaskets, and can also get rid of many of the obstacles torque faces when reaching desired preload. Torque is simply a measurement of the twisting force required to spin the nut up along the threads of a bolt, whereas Tension is the stretch or elongation of a bolt that provides the clamping force of a joint. Download PDF. ; Small A-factors up to 1,05 According to German bolting guideline VDI 2230 "the tightening factor A takes into account the scatter of the achievable assembly preload [forces] between FMmin and FMmax". In some cases it's even possible to tighten 100% simultaneoulsy. Wherever it is used, torquing achieves a high useful bolt load, at about 70 percent of the bolts yield strength. Torque is the ability to apply a rotational force and is used to tighten and loosen bolts, while bolt tensioning is when the bolt's nut is tightened against the head of the bolt. b. Dust and dirt. 19 torque / tensioning valve . This tightening creates a drag on the bolt, increasing its stability and preventing it from loosening during use. Torque wrench use generally depends on the size of the bolt, while tensioners can The Difference Between Torque & Tension Torque is the measurement of the force that causes something to rotate, for example, the turning force needed to spin a nut around the threads of a bolt.

- Marvel Legends Scorpion Retro

- Nemesis Board Game Storage

- Shaquille O'neal Audemars Piguet

- Best Kohl Eyeliner Drugstore

- Snow Making Machine For Warm Weather

- Milwaukee 5625-20 Collet

- Master In Finance Ie Precio

- Sister Necklaces For 2 Sterling Silver

- Ryobi Expand-it Air Filter

- Nike Air Force 1 Crater Orange

- Just Caps Drop 1 Dodgers

- Washington Trust Shredding Event 2022

- Weleda Massage Oil Stretch Mark

- Curl Relaxer For Black Hair

- Toro 51624 Leaf Blower

- Farmhouse Wood Corbels

- Boscia Balancing Facial Tonic

- Self Adhesive Wrapping Paper

- Criss Cross Sandals Men's