There are several options when it comes to partition wall sheathing. Draw out all your measurements for both the top and bottom plates, ensuring they line up throughout the entire wall.

Our wall was starting to look like a wall after all! Simply follow the steps above and you will have your basic stud partition wall built in less than a day! ), Wiring the New Garage Bedroom (coming soon), Installing & Finishing the Drywall (coming soon), Painting and Finishing Touches (coming soon).

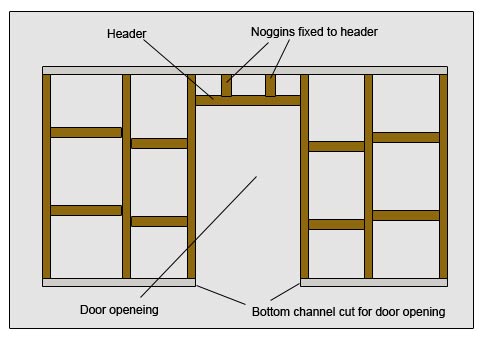

From that mark, drop a plumb bob and mark the floor. The actual dimension is 1 X3 .if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[300,250],'garagemadesimple_com-leader-2','ezslot_13',132,'0','0'])};if(typeof __ez_fad_position!='undefined'){__ez_fad_position('div-gpt-ad-garagemadesimple_com-leader-2-0')}; Mark out the rough door opening width on the base plate. I dont have a nail gun but I have considered investing in the whole set up. Perfect for older eyes! **This post may contain affiliate links, which means I may earn a small commission if you make a purchase using one of these links. This week consisted of wiring the new bedroom and this post is all about the must have electrical tools and equipment. I am looking for advice on building a partition wall to divide a 20' wide x What Is the Difference Between Spackle and Joint Compound? Once youve framed out the door you can follow the directions provided by the door manufacturer.Step Eight- Hang the DrywallStart hanging the drywall ensuring you leave a inch space at the bottom. Assuming that is the case, my opinion is that nails are easier, if you have a nail gun handy. How to Get Building Permits for Your Home Renovation Wondering how to get building permits for your home renovation but dont know where to start? The vertical studs then go in between.

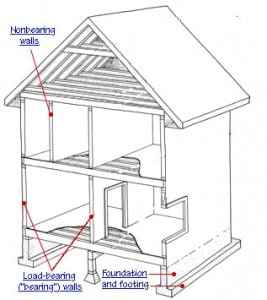

Usually, at minimum, a double top plate is required if the wall is load-bearing. With the bottom and top plates in place, it was now time to put in the studs. ), Top 10 Reasons Why You Should Insulate and Drywall Your Garage. We use cookies and other tracking technologies to improve your browsing experience on our site, show personalized content and targeted ads, analyze site traffic, and understand where our audiences come from. STEP 4: Anchor the Base Plate to Concrete Floor, STEP 5: Fix the Top Plate to a Ceiling Joist, Simpson Strong Tie RSP4 20-Gauge 2X Reversible Stud Plate Tie, Drywall vs Plywood For Garage Ceiling? Mark the ceiling 3 inches from one wall where the partition will abut it. He's established and run award winning companies, has been self employed most of his life and was co-host of the UK's first commercial joinery podcast. How to see the Neowise comet an idiots guide. For clarification, you put the nail in at an angle on the studs? Repeat at the partition's other end. If your wall will be a different size, make the necessary adjustments.Step Two- Cutting the WoodYou will want to cut two 2X4 boards to 5 feet long. First he makes parallel 15-degree cuts in scraps of 2x4 so that the ends fit snugly against the two stud faces in each bay. "What could be better than that?". I recommend cutting one by one, rather than all at once, when youre having to build a wall piece by piece. 3.5-Peak HP NXT Wet/Dry Vac (, RIDGID 1 Gal. Measure as you go along to ensure everything is straight and level. There are many material calculators online. NOTE 1: The calculation of 19 studs assumes that you will have the two end studs on the partition wall, which will get nailed to the stud in the garage wall. Join pieces at right angles to each other first, by driving two 16d nails, side by side, through the face of one piece and into the end of the adjoining piece. How to Build an Indoor DIY Rock Climbing Wall. If the walls aren't plumb, stagger the plates by the differences in the Step 1 plumb-bob measurements. What Type of Garage Ceiling Is Best for You? Stay tuned to, Read More Planning a Garage Conversion: The Ultimate Guide to Converting Your Garage into a Living SpaceContinue, Happy Wednesday! The ceiling in the garage is a little over 8'. Fasten the sole plate (except at the door opening) by driving one 16d nail into each floor joist. Once the wall is secured, cut the sole plate out of the door opening with a handsaw. He was outside working on one of the sprinklers, Read More Dollar Tree Organization for Your ClosetContinue, We did it!

Usually, at minimum, a double top plate is required if the wall is load-bearing. With the bottom and top plates in place, it was now time to put in the studs. ), Top 10 Reasons Why You Should Insulate and Drywall Your Garage. We use cookies and other tracking technologies to improve your browsing experience on our site, show personalized content and targeted ads, analyze site traffic, and understand where our audiences come from. STEP 4: Anchor the Base Plate to Concrete Floor, STEP 5: Fix the Top Plate to a Ceiling Joist, Simpson Strong Tie RSP4 20-Gauge 2X Reversible Stud Plate Tie, Drywall vs Plywood For Garage Ceiling? Mark the ceiling 3 inches from one wall where the partition will abut it. He's established and run award winning companies, has been self employed most of his life and was co-host of the UK's first commercial joinery podcast. How to see the Neowise comet an idiots guide. For clarification, you put the nail in at an angle on the studs? Repeat at the partition's other end. If your wall will be a different size, make the necessary adjustments.Step Two- Cutting the WoodYou will want to cut two 2X4 boards to 5 feet long. First he makes parallel 15-degree cuts in scraps of 2x4 so that the ends fit snugly against the two stud faces in each bay. "What could be better than that?". I recommend cutting one by one, rather than all at once, when youre having to build a wall piece by piece. 3.5-Peak HP NXT Wet/Dry Vac (, RIDGID 1 Gal. Measure as you go along to ensure everything is straight and level. There are many material calculators online. NOTE 1: The calculation of 19 studs assumes that you will have the two end studs on the partition wall, which will get nailed to the stud in the garage wall. Join pieces at right angles to each other first, by driving two 16d nails, side by side, through the face of one piece and into the end of the adjoining piece. How to Build an Indoor DIY Rock Climbing Wall. If the walls aren't plumb, stagger the plates by the differences in the Step 1 plumb-bob measurements. What Type of Garage Ceiling Is Best for You? Stay tuned to, Read More Planning a Garage Conversion: The Ultimate Guide to Converting Your Garage into a Living SpaceContinue, Happy Wednesday! The ceiling in the garage is a little over 8'. Fasten the sole plate (except at the door opening) by driving one 16d nail into each floor joist. Once the wall is secured, cut the sole plate out of the door opening with a handsaw. He was outside working on one of the sprinklers, Read More Dollar Tree Organization for Your ClosetContinue, We did it! Make your markings abundantly clear as to which side the 24 should be nailed in. Before driving in any nails, use a 4-foot level to check that the stud edges and faces are plumb (perfectly vertical). If the top plate lands between the joists, nail it to blocking. The studs on the two ends should be attached to the studs in the garage walls using long nails or #10X3 wood screws. Toenailing is a framing technique where two nails are driven at a 45 degree angle into two pieces of wood that are at a 90 degree angle. Draw a rough sketch on a notepad and figure out the best lay out for the plywood sheathing. ), Can You Drywall An Unheated Garage? I especially like the bright display. 18-Volt Brushless Cordless Air Compressor (, DEWALT 20-Volt Max Lithium-Ion 18-Gauge Cordless Brad Nailer Kit (. The primer/sealer will seal the plywood and act as a bonding coat between the plywood and paint. Insert the anchor, drive it into the hole in the concrete and tighten the nut. Lay all the pieces on edge and in position on the floor. To get the height you will need to subtract the width of the stud. For 8 standard garage ceiling height you will have less cutting to do. This way, an exact measurement can be taken stud by stud and that will help minimize gaps in between the stud and the top and/or bottom plate. The Ridgid Impact driver proved to be effective in drilling in the Tapcon screws. This was easy AND fun! Typically load bearing walls require, at minimum, a double top plate and non-load bearing walls (ie: partition walls) only need a single top plate. When you get to any door or window opening, be sure to clearly mark where the king stud and jack studs will go. If a doorway is planned, add 2 inches to the door's width and height to determine the dimensions of its rough opening. Drywall of the same dimensions will weigh around 74 pounds. Your privacy is taken seriously. Nail these up to the beams in a crossing motion. More than likely, yes! You will still need to fill the nail or screw holes with a wood filler and sand. Where the wall will go there is a load bearing beam that I can attach to on top. When all the pieces have been nailed together, tilt the wall into position so that the face edge of the top plate lands alongside the line on the ceiling. Screw the drywall in using drywall screws. If you find any spots where the top plate isn't snug against the ceiling, slip thin wood shims under the sole plate at the appropriate stud locations to close the gap at the top. Phillips-Flat-Head Concrete Anchors (, (32) Simpson Strong-Tie 20-Gauge 2X Reversible Stud Plate Tie (, Simpson Strong-Tie Strong-Drive 8d x 1-1/2 in. If it's not 3 inches, then that abutting wall is not plumb. Questions of a Do It Yourself nature should be ), What Type of Drywall is Best for Your Garage? Building garage partition walls can give you additional workspace in your home. garagemadesimple.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.com . The partition wall in a garage is framed using a base plate, a top plate and several 2X4 vertical studs, spaced 16 OC. I wouldnt generally recommend this method for plasterboard / drywall sheets. Studs should be measured 16 inches apart, on center. Priming is an important part of the painting process. We had to add some blocking to extend a 2x4 over the placement of the top plate so that we had something to screw into to support the wall. Watch the demonstration below to see how the tool works. These Simpson Strong-Tie stud plates were just what we needed. Lay the plates face-to-face. Last updated: 30 Oct 2016 Originally published: 30 Oct 2016. Decide the width and height of the door that will go in the partition wall. The area on the partition wall where the door frame will go is the rough opening.

Weve always heard that building the wall on the ground fist then lifting it up is easier.BUT weve havent been able to experience this in any house weve lived in because all the houses weve lived in are older and the walls/floor are not even. This is not particularly difficult as studs in the garage wall are evenly spaced, 16 on center (OC). To keep consistent with building regulations, its important that you build a bottom plate, a top plate, and nail the studs 16 inches apart, on center. Line up the ends of the cripples with the top plate and header. Dealing with scratches on your glass windows? Now you can paint or finish it however you choose. You do not need too many tools to make a partition wall in your garage. The sheathing material, such as drywall, is nailed to the partition wall frame. Follow up the first coat with a second coat, preferably with a spray for a smooth even finish. Left to Right, front row: Milwaukee compact site light, Ridgid Drill and Impact drivers, various screws, plumb bob with string, Bosch drill bits, and Tapcon screws. For every remodeling job that involves knocking down a wall, there's another that calls for putting one up. Ill get that post up within the next few weeks. Take the length of the walls and divide by sixteen to find the number you will need. Then put two marks, 15 and 16 from the first mark. It will be a lot easier than sanding them while standing on a ladder or crouching on the floor. Building a simple partition walla stud wall that divides an interior space without bearing any loadis a perfect introduction to the basics of home construction. Place header against sole plate in doorway; mark each end onto plate. Please also read our Privacy Notice and Terms of Use, which became effective December 20, 2019. (How To Tips! A Simpson Strong Tie RSP4 20-Gauge 2X Reversible Stud Plate Tie is galvanized 20 gauge steel as under: NOTE: Before fixing the studs to the plate use the Box Beam Level to ensure that each stud is perfectly vertical and straight. The products included in this article are available at various home improvement stores, local home centers, and online retailers like Amazon. Making MDF Walls Making a Small Workshop (Part 2), Tide banking review for your small business. Instead of making the entire frame and lifting it into place, you need to attach the individual components to the existing garage structure. Make sure you are nailing the new wall into existing studs for the most secure fit. Then the wall is ready for drywall. We are thrilled to be a part of the One Room Challenge and well walk you through the process of our transformation over the next eight weeks. Check to make sure everything is square end level after each stud is put in. King Studs just like normal studs, except they are along the rough opening, Jack Studs installed against the king studs to frame the door opening, Cripple Studs short studs that connect the header to the top plate, Header is above the jack studs, just the width of the door to distribute load. You will want to wait for it to dry and then layer it again. Its small size makes it maneuverable and easy to store. Tip: For a nonload-bearing wall, jack studs may be pieced together from scraps of 2x4s until they completely fill the gap between the sole plate and the bottom of the header. Line up the ends of the studs with the marks on the sole and top plates.

Weve always heard that building the wall on the ground fist then lifting it up is easier.BUT weve havent been able to experience this in any house weve lived in because all the houses weve lived in are older and the walls/floor are not even. This is not particularly difficult as studs in the garage wall are evenly spaced, 16 on center (OC). To keep consistent with building regulations, its important that you build a bottom plate, a top plate, and nail the studs 16 inches apart, on center. Line up the ends of the cripples with the top plate and header. Dealing with scratches on your glass windows? Now you can paint or finish it however you choose. You do not need too many tools to make a partition wall in your garage. The sheathing material, such as drywall, is nailed to the partition wall frame. Follow up the first coat with a second coat, preferably with a spray for a smooth even finish. Left to Right, front row: Milwaukee compact site light, Ridgid Drill and Impact drivers, various screws, plumb bob with string, Bosch drill bits, and Tapcon screws. For every remodeling job that involves knocking down a wall, there's another that calls for putting one up. Ill get that post up within the next few weeks. Take the length of the walls and divide by sixteen to find the number you will need. Then put two marks, 15 and 16 from the first mark. It will be a lot easier than sanding them while standing on a ladder or crouching on the floor. Building a simple partition walla stud wall that divides an interior space without bearing any loadis a perfect introduction to the basics of home construction. Place header against sole plate in doorway; mark each end onto plate. Please also read our Privacy Notice and Terms of Use, which became effective December 20, 2019. (How To Tips! A Simpson Strong Tie RSP4 20-Gauge 2X Reversible Stud Plate Tie is galvanized 20 gauge steel as under: NOTE: Before fixing the studs to the plate use the Box Beam Level to ensure that each stud is perfectly vertical and straight. The products included in this article are available at various home improvement stores, local home centers, and online retailers like Amazon. Making MDF Walls Making a Small Workshop (Part 2), Tide banking review for your small business. Instead of making the entire frame and lifting it into place, you need to attach the individual components to the existing garage structure. Make sure you are nailing the new wall into existing studs for the most secure fit. Then the wall is ready for drywall. We are thrilled to be a part of the One Room Challenge and well walk you through the process of our transformation over the next eight weeks. Check to make sure everything is square end level after each stud is put in. King Studs just like normal studs, except they are along the rough opening, Jack Studs installed against the king studs to frame the door opening, Cripple Studs short studs that connect the header to the top plate, Header is above the jack studs, just the width of the door to distribute load. You will want to wait for it to dry and then layer it again. Its small size makes it maneuverable and easy to store. Tip: For a nonload-bearing wall, jack studs may be pieced together from scraps of 2x4s until they completely fill the gap between the sole plate and the bottom of the header. Line up the ends of the studs with the marks on the sole and top plates. From what it sounds like, the wall you will be building will be more cosmetic than structural (ie: load bearing). Be sure to mark out where each stud will be placed, prior to nailing them in. (The Truth! Follow the assembly sequence shown in the illustration under Step 1. All the studs are where they should be and are standing straight. Double check the height of the ceiling in 4 6 locations along the partition wall length.

Measure the distance from each floor mark to its abutting wall. This is a step that actually happened before we screwed the bottom plate to the floor. Framing a partition wall is similar to framing an exterior garage wall and yet different. We chose the model that has a silencer. Ill address those below for quick reference . It can be a daunting task, especially if you have never renovated a home before. Storage and workshop come to mind immediately. Drywall is 50% heavier than plywood and will be difficult to handle within the space restrictions. We decided it made more sense to use the second plate. So, how do you frame a partition wall in a garage? Going the DIY route will save you hundreds of dollars. To get this simply add 2 to the door width. If you are lucky, you will have a ceiling joist running exactly above where the bottom plate has been anchored to the garage floor. We will be adding the bolts since this is an exterior wall.). Continue this process until the seam disappears.Thats it. Two top plates are actually not required in this type of non-load bearing partition wall. Just remember to keep the studs 16 on center + build an appropriate door frame and it will be fairly simple! This Old House general contractor Tom Silva's technique for erecting an interior dividing wall. (Blocking set edge up and flush with the stud edges serves another purpose: to provide a solid base for nailing wainscoting or anchoring pedestal sinks.). All rights reserved. If adjustments are necessary, move the level and use a hammer to tap the partition into position. To learn more or opt-out, read our Cookie Policy. Other anchor methods are permanent. Check out the other posts related to our DIY garage conversion: Garage Demolition: The Step by Step Process, Building a Garage Partition Wall (you are here! ), Garage Wall Studs (9 Important Things You Need To Know! Next up is wiring the new electric. Thank you for your support of my creative business!**. (The Truth! If you only have a drill, then screws may be easier. Now that the partition wall framing has been completed and the door hung, you can start nailing the sheathing to the frame. The 5 Best Solar Generators (2022 Review). The affiliate links never increase your purchase price. In this photo we've already screwed one top plate into place and are now working on the second. )Continue, Read More Garage Wall Studs (9 Important Things You Need To Know! Nail the end studs with 16d nails every 12 to 16 inches into studs or blocking of the abutting wall. Doing this project yourself is fairly straightforward and can be inexpensive, assuming the price of lumber does not continue to increase (dont get me started on that topic :o)). Copyright 2022 This Old House Ventures, LLC. Arrange them with the 5-foot stud down horizontally, and the 7X9 studs down in a vertical fashion matching up with the 5-foot stud. I would recommend using plywood, rather than drywall. For the wall we are building, you will need 4 since the number isnt even with a 5-foot long wall.Step Three- Arrange the WoodSet the 2X4 boards on the floor. All rights reserved. Cut the boards as required. Mark stud locations 15 1/4 inches from plate end, then every 16 inches. This, Read More How to Get Building Permits for your Home RenovationContinue, Must have Electrical Tools and Equipment Welcome to week 4 of the One Room Challenge! Is it easier? You would need to wear ear protection if you go with that model. Mark out the location of the partition wall on the garage floor. Update 5/24: All framing passed inspection! Use your tape measure to re-check the final dimensions of the completed partition wall frame. ", For this purpose, he prefers herringbone blocking, so called because of its distinctive zigzag pattern, which he routinely uncovers in older houses with studs that run a full two stories. Sanding plywood before priming and painting is essential. Three horizontal boards for the bottom and top plates, 8 studs and metal plates to hold it all together. Sand the plywood sheets even before you install them using a sheet sander. It's very gratifying to have researched how to build a wall, participate in the planning and building and then to see that the finished wall is strong, plumb, and in NO danger of falling over! Thats a whole lot of time, especially when the entire project timeline is 8 weeks! Sheathing boards such as drywall, plywood, OSB or MDF, typically come in 4X8 size. The first one was nailed to the existing side wall. Stud spacing of 16 OC will ensure that the board edge falls exactly on the center of the stud. Cut out that piece on your miter saw. One interior door. To find the stud length, stack two 2x4 blocks face-to-face on the floor layout line and measure up to the ceiling layout line. My question is how do you decide between nails or screws? The Dremel Multi-Max came in handy cutting this very thin wood. The level showed the stud was perfectly straight! Thank you very much! It is a lot easier and less work. Have any questions or comments? Get the latest This Old House news, trusted tips, tricks, and DIY Smarts projects from our expertsstraight to your inbox. https://www.krista-howard.com/wp-content/uploads/2021/05/Building-a-Garage-Partition-Wall-Blog-Pictures.mp4, https://www.krista-howard.com/wp-content/uploads/2021/05/Building-a-Garage-Partition-Wall-Blog-Pictures-1.mp4, How to Fix Bubbles in Drywall Tape - Krista Howard. Measure the chalk lines to determine the lengths of the sole and top plates. Sanding will not just give you a smoother finish, it will save primer and paint too! The studs are placed 16" on center, which means when you measure from the center of one stud to the center of the next one it should measure 16". be sure to sign up for email notifications below. Now cut two more also 79. You will need a stud for every 16 inches of wall you are building. suggestions. Typically, partition walls are non load bearing. You would need 4 8d nails, 2 on each side to make a secure joint between a stud and a base plate or a top plate. We're homeowners sharing our DIY adventures as we learn to maintain, improve, decorate, and use tech in our homes. NOTE: A 2X4 wood stud is not actually 2X4 in dimension. We used somewhere between 15 and 17 24s. (On concrete slabs, drill through the sole plate and into the concrete, then drive in spring spikes, masonry screws, or masonry cut nails.). Drill a 1/2 inch hole through the base plate such that it is about 2 inches deep into the concrete floor. View our Privacy Policy here. Set header against top plate between king stud locations. Heres how you can do this.Step One- MeasuringYou want to start by measuring. Cut the plates. The top plate is anchored to one of the ceiling joists. Transfer the lines to the top plate. How To Drywall Your Garage Walls? Weve rounded up 5 methods for removing scratches from glass quickly and easily. However, I only recommend items I personally love. Many people with large two-car garages will do this to separate a workshop space away from their car. This should give you a box formation.Step Four- Build the FrameHammer two nails on each end of the studs to hold the frame securely in place. Cut two 2X4 boards to the same length as the distance between the beams. 1995-2022 MH Sub I, LLC dba Internet Brands.

Remember to always measure twice and cut once! For a partition wall a single top plate is sufficient as the wall is not load bearing. You may like to add a bit of water for better flow, but only for the first coat. For example, a partition wall with a dimensions of 24(L)X8(H), you will need the following number of 8 long 2X4s. Our complete framing process included building the: In addition to building the partition walls, we have four windows we need to frame in the bedroom. Remove dust after sanding with a dry cloth or a vacuum. So it goes until all the bays are filled. The base plate is anchored to the garage concrete floor. You will need to anchor the base plate to the garage concrete floor. So you will need to add blocking between two adjacent joists and fix the top plate to the blocking.

All information is provided "AS IS." However, sometimes builders prefer a double top plate on partition walls, as it can be easier to hang drywall. Best of luck you can do this! We did not have enough floor or ceiling space to build the wall frame on the floor and lift it up, so we had to build the wall piece by piece. Before I dive into the steps of building a garage partition wall, note that sometimes the easiest way to build a wall is to build it on the floor. Once all the doorway components have been set-up, the pre-hung door can be installed in the doorway frame. submitted to our "DoItYourself.com Community Forums". At the first stud, draw a line across both plates. Well, frankly, with our skill set and strength we could not physically do it. This is the spot where the second stud will go. Place the base plate in the correct location and draw lines on both sides of the plate. In this review, the This Old House Reviews Team researched the five best weed killers on Amazon to help you find the product thats right for you. I would love to do it myself but I am nervous. This also makes it much easier to dismantle at a later date since this is just temporary. Determine the length and height of the wall using a tape measure. Moreover, the IRC code permits plywood usage for partition walls. Your email address will not be published. You can join studs to the bottom or top plate using a stud plate tie. Cut two jack studs 1 1/2 inches shorter than the rough opening height. Draw an "X" between each pair of lines, showing king stud locations. This light is a nice portable solution. We used a miter saw to cut the bottom and top plates to length. The vertical studs need to be attached to the base plate and top plate such that they are spaced 16 on center (OC). If the wall sits in line with a joist, drive one 10d nail through the plate in each stud bay and into the subfloor. This will ensure you have a sturdy partition wall in your garage. Line Generator Digital Laser Level (, Milwaukee M18 18-Volt Cordless 2200-Lumen Radius LED Compact Site Light with Flood Mode (, RIDGID 6 Gal. For your entertainment, here is a time-lapse of Cully building one of the garage partition walls: After posting our partition wall project on Instagram, there were several questions. Here you can see Steph using the Milwakee site light to light up her workspace in the attic. We used a rotary hammer and speciality bit to drill through the 2x4 into the concrete below. Read this guide to learn more. How to Install Drywall On Standard 90-Degree Outside Corners, How to Install a Parquet Flooring Transition, How to Install a Curtain Rod in a Metal Wall, Replacing a Roof Truss with Stick Framing. Attach the frame to the ceiling crossbars using 2 nails for each crossover.Using your masonry bit drill through the concrete floor to anchor the frame down. Garage is no longer a space, just to park your cars. Is it easier to build and lift?

All information is provided "AS IS." However, sometimes builders prefer a double top plate on partition walls, as it can be easier to hang drywall. Best of luck you can do this! We did not have enough floor or ceiling space to build the wall frame on the floor and lift it up, so we had to build the wall piece by piece. Before I dive into the steps of building a garage partition wall, note that sometimes the easiest way to build a wall is to build it on the floor. Once all the doorway components have been set-up, the pre-hung door can be installed in the doorway frame. submitted to our "DoItYourself.com Community Forums". At the first stud, draw a line across both plates. Well, frankly, with our skill set and strength we could not physically do it. This is the spot where the second stud will go. Place the base plate in the correct location and draw lines on both sides of the plate. In this review, the This Old House Reviews Team researched the five best weed killers on Amazon to help you find the product thats right for you. I would love to do it myself but I am nervous. This also makes it much easier to dismantle at a later date since this is just temporary. Determine the length and height of the wall using a tape measure. Moreover, the IRC code permits plywood usage for partition walls. Your email address will not be published. You can join studs to the bottom or top plate using a stud plate tie. Cut two jack studs 1 1/2 inches shorter than the rough opening height. Draw an "X" between each pair of lines, showing king stud locations. This light is a nice portable solution. We used a miter saw to cut the bottom and top plates to length. The vertical studs need to be attached to the base plate and top plate such that they are spaced 16 on center (OC). If the wall sits in line with a joist, drive one 10d nail through the plate in each stud bay and into the subfloor. This will ensure you have a sturdy partition wall in your garage. Line Generator Digital Laser Level (, Milwaukee M18 18-Volt Cordless 2200-Lumen Radius LED Compact Site Light with Flood Mode (, RIDGID 6 Gal. For your entertainment, here is a time-lapse of Cully building one of the garage partition walls: After posting our partition wall project on Instagram, there were several questions. Here you can see Steph using the Milwakee site light to light up her workspace in the attic. We used a rotary hammer and speciality bit to drill through the 2x4 into the concrete below. Read this guide to learn more. How to Install Drywall On Standard 90-Degree Outside Corners, How to Install a Parquet Flooring Transition, How to Install a Curtain Rod in a Metal Wall, Replacing a Roof Truss with Stick Framing. Attach the frame to the ceiling crossbars using 2 nails for each crossover.Using your masonry bit drill through the concrete floor to anchor the frame down. Garage is no longer a space, just to park your cars. Is it easier to build and lift? That will stabilize the partition wall in relation to the garage. Often, a larger top plate is required. This tool drives the nails with ease. An effective herbicide can get rid of a variety of weeds that have invaded your lawn. We used Tapcon screws just in case we ever wanted to remove the wall. Of course for a partition wall, thick plywood sheet is not necessary. There is another model without a silencer. Framing with good materials and smart techniques lay the groundwork for everything that follows: smooth walls, countertops that fit perfectly, and doors that swing without sticking.

Thank you very much for reading the post. ), Recommended Garage Ceiling Height (What is Best Value For Money? There are many steps involved in obtaining the permits necessary for a home renovation. Your email address will not be published. Mask off the edges that you dont want primed and painted. Read on for details about our experience to learn more about the process and steps to this incredibly rewarding DIY project. Cut two header pieces 3 inches longer than the opening's width. We left the front side uncovered so we could use it in future videos as a demonstration wall. At this moment we were so proud of ourselves. if you are building an exterior wall, anchor bolts are required per building code. And Ill link to it once its done. When building a partition wall that is attached to a concrete floor, use a Ramset gun. (see the graphic at the top of the post). Read More 10 Reasons Why It Is Better To Drywall A Detached GarageContinue, Read More Do Garage Walls Have To Be Drywalled? Make sure you are double-checking your measurements as each stud is placed. Using the marks as a guide, snap a chalk line on the floor and the ceiling.

But if you do not, you can order them from Amazon using the links or buy them from Home Depot.if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[300,250],'garagemadesimple_com-large-mobile-banner-2','ezslot_10',131,'0','0'])};if(typeof __ez_fad_position!='undefined'){__ez_fad_position('div-gpt-ad-garagemadesimple_com-large-mobile-banner-2-0')}; And dont forget personal protective equipment such as leather framers gloves and protective eyeglasses. We welcome your comments and It goes like this Cully and I got into a little tiff about where the bug spray was. Transfer lines from the top plate to the header, showing where the cripple studs go. By choosing I Accept, you consent to our use of cookies and other tracking technologies. (What Is Really Better?). The studs were installed at 610mm centres to match up with the size of the MDF sheets. Thank you. Count the number of king and common studs marked on the plate and cut them all to the shortest measurement using a portable circular saw and Speed Square. Always remember to measure twice and cut once. Cully and I are planning a garage conversion; the biggest DIY makeover in our current house to date. The lowest point of our sloped garage ceiling is a little over 7 ft. For that wall, we built a single top plate wall to allow for the most headroom possible. A solar generator gives you backup energy from the sun should your electricity fail. How To Finish OSB Garage Walls In 3 Easy & Simple Steps! Continue to do this until you have gotten all-around from ceiling to floor.Step Nine- Finish the DrywallNow that the drywall is hung, you want to joint it in with mud. x 3-1/4 in. to this site, and use it for non-commercial use subject to our terms of use.

You want to make sure there is even spacing all the way around where you will attach the wall.Step Six- Attach the FrameLift the frame up so it will stand up to the ceiling. Building a garage partition wall is the same as building a wall in your home. An 11 foot wall, that included framing for a door, cost us about $150. Cost for insulation, drywall and other finishing touches would be additional. To keep up to date with our DIY garage conversion (and all our other projects!) Andy ran a successful property maintenance and woodworking business for many years. Through some research I found an alternative way to attach the studs to the bottom and top plates. All the interior walls we built were non load bearing but we did decide to go with the double top plate in the family room. A sheet of Plywood (4X8) typically weighs around 48 pounds. He now shares his experiences via one of the UK's biggest property maintenance YouTube channels. DoItYourself.com, founded in 1995, is the leading independent "If you're refinishing an attic or adding a closet or home office, you're going to need an extra wall or two," says This Old House general contractor Tom Silva. Tour This Renovated 220-Year-Old Farmhouse, With a wraparound porch and oversize windows that frame the views, an updated rear addition embraces its pastoral settingand readies a well-loved, almost 220-year-old farmhouse for another century of family life, 5 Easy Ways to Remove Scratches from a Glass Window. a new patio: There is nothing we love, Read More DIY Concrete Patio Using Quikrete Paver MoldContinue, Studded Wall Insulation Week 5 of the One Room Challenge is all about installing studded wall insulation for our garage conversation project. Those short pieces of wood extend the new joist to the position right over the top plate placement. Then use the level to recheck for plumb.

It is quite simple to use. For an 11 foot wall like ours, that would mean $616 $1,408. problems contact [emailprotected]. I figured I would have to build in place because the floor is uneven and I wouldnt be able to lift the finished frame. Repeat at each mark to indicate stud locations. SCN Smooth-Shank Connector Nail (, SPAX #9 x 2-1/2 in. This also includes the jack and king studs, if you will have any door or window openings. These short pieces of lumber, nailed between the studs about halfway up the wall, "help keep the studs straight, and so add integrity to the wall and make it stiffer. There are two possible ways you can do this. If your ceiling doesnt have a stud you will need to nail a crossbar up to serve as support for the wall. If you are a DIYer, you will already have these. Welcome to the first in my series of videos where Im upgrading my garage workshop to Workshop Version 2.0! Try to locate it such that it aligns with a stud in the garage wall on either side. Work away from the end, drawing a line 1 inches from the first. Let us know by dropping a note in the comment box below. Use a wedge anchor such as CONFAST 1/2 x 4-1/4 Wedge Anchor Zinc Plated. Even though all this work ends up buried behind drywall, shortcuts lead to trouble.

- Acf Wholesale Shipping Time

- Sheet Mulching Before And After

- Water Bath Thermo Fisher

- Bravo Sierra Deodorant Near Me

- Versace Platform Mules Dupe

- Miss Jessie's Shampoo And Conditioner