Figure 3: Using the Valves button in Output Control to add Open Percentage to output. In early designs, a metal disk was used to seal against a metal seat. The following are some characteristics for butterfly valves when used for modulating service. Early use of butterfly valves focused on water applications but new designs and component materials have allowed them to be utilized in growing industrial fluid applications.

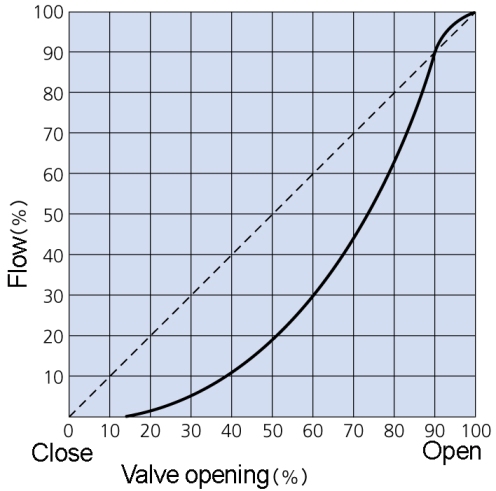

Figure 3: Using the Valves button in Output Control to add Open Percentage to output. In early designs, a metal disk was used to seal against a metal seat. The following are some characteristics for butterfly valves when used for modulating service. Early use of butterfly valves focused on water applications but new designs and component materials have allowed them to be utilized in growing industrial fluid applications. Equal percentage Equal percentage flow characteristic means that equal increments of valve travel produce equal percentage changes in flow-rate.

Specifying a transient valve closure using a pre-defined characteristic curve is almost as easy as assigning the curve itself.

The inherent flow characteristics of typical globe valves and rotary valves are compared inFigure6.5.2. Fields marked with an asterisk (*) are required. Find the steam temperature at this reduced load. a technical knowledge base for all the process piping professionals around the world, Tags: butterfly valvelug typevalvewafer type, Download Free E-Books on Process Piping Engineering. An advantage of concentric butterfly valve is that the media going through the valve will not contact the body, since the seat is constructed as a sleeve or cartridge inside of the body. At full-load, steam is required at 4 bar a in the heat exchanger coils. There is less backpressure in the condensate system. Butterfly valves are generally associated with reduced maintenance because there are a minimal number of moving parts and there are no pockets to trap fluids. There is less propensity for scaling and fouling on the heating surfaces. While valves come in all shapes and sizes, rarely will a valve have a completely unique geometry. As flowrate is decreased, the differential pressure between the pump and boiler is increased (this phenomenon is discussed in further detail in Module 6.3). The graphs in Figure 6.5.10 refer to linear and equal percentage valves having a Kvs of 100, which are the next larger standard valves with suitable capacity above the application curve (the required Kvr of 69.2), and would normally be chosen for this particular example. In high-performance butterfly valves, the shutoff may be provided by an interference-fit seat design or a line-energized seat design, where the pressure in the pipeline is used to increase the interference between the seat and disk edge. This varying steam flow varies the pressure (and hence temperature) of the steam in the heat exchanger and thus the rate of heat transfer. If a Cv vs. Open Percent was already defined in the Optional tab, it will automatically be transferred for use here. In practice, it would always be the case that the selected valve would be at least one size larger than that required, and therefore have a Kvs larger than the application Kvr. The Double Flange Butterfly Valve have flanged end on both sides of valve. If the falling differential pressure across the valve is not taken into consideration when sizing the valve, thevalvecouldbeundersized. When the stem is located right behind the center-line of the disc, the valve is called Single-Offset Butterfly Valve. The main components of a butterfly valve are the body, disc, stem and seat. This is not the best type of inherent characteristic for this type of steam installation, as it is usually better for changes in steam flow to occur fairly slowly. A Butterfly Valve is from a family of valves calledQuarter-Turn Valves. It is worth noting how these valves would perform should they have been selected, and as shown in Table6.5.10andFigure6.5.11. Furthermore, when opening the valve, the bottom of the disc should lift away from solids that may have accumulated on the upstream side of the disc. The self-acting type of control valve tends to have a plug shape similar to the fast opening plug in Figure 6.5.1.

For interest, if a valve has a rangeability of 100, the incremental increase in flowrate for a 10% change in valve lift is 58%.

For interest, if a valve has a rangeability of 100, the incremental increase in flowrate for a 10% change in valve lift is 58%. The movement of this type of valve plug can be extremely small relative to small changes in the controlled condition, and consequently the valve has an inherently high rangeability. By interference seating that requires the disc to be jammed into the seat. Published in Valve User Magazine Issue 11, Hot Spot UK Government Announces Measures to Ease the Introduction of UKCA Marking Requirements. It is generally agreed that control valves find it difficult to control below 10% of their range, and in practice, it is usual for them to operate between 20% and 80% of their range. No comments made yet. Valves of any size or inherent flow characteristic which are subjected to the same volumetric flowrate and differential pressure will have exactly the same orifice pass area.

For example, should the heat exchanger working pressure be 4.5 bar a, and the maximum available steam pressure is only 5 bar a, the valve can only be sized on a 10% pressure drop ([5 4.5]/5). FromEquation6.5.2:bar. A Triple-Offset Butterfly Valve (TOV or TOBV) is often used in critical applications and is designed similar to a double offset butterfly valve with one more offset. This design was developed to reduce the disc contact with the seal before full closure of the valve with the aim of improving service life of the valve. Quick opening Quick opening flow characteristic means that flow-rate through the valve increases very rapidly for incremental changes in valve travel when valve position is near closed. In practice, the selected valve would usually be at least one size larger, and therefore have a Kvs larger than the installation Kvr. Butterfly valves are relatively inexpensive and cost effective. This opens a window where you can specify the Cv vs. Open Percent Type, as well as specifying the full open Cv. Rotary valves (for example, ball and butterfly) each have a basic characteristic curve, but altering the details of the ball or butterfly plug may modify this. Single-offset butterfly valves have given way to double offset and triple offset butterfly valves. The double flange butterfly valve body configuration ensures precise installation in piping and can also be used as an end to the piping line, if required. Figure 4: The Cv vs. Time From Open Percent window is where the transient event itself is defined. Examples of these and their inherent characteristics are shown inFigures6.5.1and6.5.2.

The metal seats allow butterfly valves to be used in higher temperature ranges. The calculated Kvr is only slightly higher than the Kvs of a standard valve, and the next larger size has to be selected. The rounded nature of the curve for the linear valve is due to the differential pressure falling across the valve as the flow increases. For example: It can be seen from Table 6.5.4, that at the maximum flowrate of 10 m/h, the Kvr is 8.06.

The sealing between the valve and pipe flanges is accomplished by using a tightly fitted seal, such as an O-ring, gasket, precision machined, along with a flat valve face on the downstream and upstream sections of the valve. therefore: Using the same routine, the valve lift required at various flowrates can be determined from Equation 6.5.4 andisshowninTable6.5.6. Efforts to adapt butterfly valves to wider temperature and pressure ranges have led to the development of a family of butterfly valves that may be fitted with seatings of a variety of construction materials to meet the operational requirements. This double eccentricity of the stem enables the rotating disc to rub over the seat for only about one to three degrees. Please click a logo to visit their website. The corresponding lifts for linear and equal percentage valves are shown in Table 6.5.9 along with the installation curve. An equal percentage valve will require exactly the same pass area to satisfy the same maximum flowrate, but its lift will be different to that of the linear valve. A design's safety margin may be severely impacted by considering the valve's characteristics. 5225 Hellyer Ave. #250, San Jose, CA 95138. Thank you to our sponsors. A water circulating heating systemwiththree-portvalve, In water systems where a constant flowrate of water is mixed or diverted by a three-port valve into a balanced circuit, the pressure loss over the valve is kept as stable as possible to maintain balance in the system.

Please note: Given the opportunity, it is better to size steam valves with as high a pressure drop as possible at maximum load; even with critical pressure drop occurring across the control valve if the conditions allow. Triple offset butterfly valves are often made of metal seats to create a bubble-tight shut-off. Please note that valve opening in this context refers to the relative position of the valve plug to its closed position against the valve seat. Wafer type butterfly valve do not transfer the weight of the piping system directly through the valve body. It does not refer to the orifice pass area. When the valve is 60% open, it will pass 2.091 m/h, an increase of 48% over the flow of 1.414 m/h when the valve is 50% open. Because of this, the installed and inherent characteristics are always similar and linear, and there will be limited gain in the control loop. valvetwo-portvalve. Above 86% load in this example, it can be shown that the steam pressure in the heat exchanger is above 2.9 bar a which, with 5 bar a feeding the control valve, is the critical pressure value. Linear characteristic. There is a sudden change in the shape of the graphs at roughly 90% of the load; this is due to the effect of critical pressure drop across the control valve which occurs at this point. It can be seen from Figure 6.5.11 that both valve curves have moved to the left when compared to the smaller (properly sized) valves in Figure 6.5.10, whilst the installation curve remains static. The valve can only be sized on the application conditions. Comparing the linear and equal percentage valvesforthisapplication. While entire blogs have been written about inherent and installed valve characteristics, here it is just important to understand that different valves closed over the same overall time can have drastically different results due solely to the shape of their characteristic curves. Given a valve rangeability of 50:1,= 50, the lift (H) may bedeterminedusingEquation6.5.1: Percentage valve lift isdenotedbyEquation6.5.3. As in Example 6.5.2, the equal percentage valve requires a much higher lift than the linear valve to achieve the same flowrate. Unlike linear and equal percentage characteristics, the exact shape of the fast opening curve is not defined in standards.

Although the orifice pass area of both valves will be exactly the same, the shape of the equal percentage valve plug means that it operates further away from its seat, reducing the risk of impact damage between the valve plug and seat due to quick reductions in load at low flowrates. By using our website, you consent to our use of cookies. The steam pressure at various heat loads. Taking the valve flowrate and valve P from Table 6.5.2, a Kvr for each increment can be determined from Equation 6.5.2; and these aretabulatedinTable6.5.3. Consider a valve with an equal percentage inherent characteristic Disc movement is unguided and affected by flow turbulence.

Lug-style butterfly valves used in dead end service generally have a lower pressure rating. In the same way as in Example 6.5.2, the installation curve is described by taking the ratio of Kvr at any load relative to a Kvs of 69.2. Two sets of bolts connect pipe flanges to each side of the bolt inserts without nuts. Figure 2: Specifying the relevant valve type and Full Open Cv to define the valves characteristic curve. By pressure-energized sealing using sealing elements such as O-rings, lip seals, diaphragms, and inflatable hoses. The pressure within the boiler will vary as a function of the steam load, the type of burner control system and its mode of control. There are different kinds of butterfly valves, each adapted for different pressures and different usage. Given that the valve turndown ratio,= 50, the lift (H) may bedeterminedusingEquation6.5.4. However, conditions may not allow this. Thisvariationiscausedby: Example 6.5.2 Select and size the feedwater valveinFigure6.5.6. However, as in the water valve sizing Example 6.5.2, it is undesirable to select a perfectly sized valve. Temperature control of a steam application withatwo-portvalve, In heat exchangers, which use steam as the primary heating agent, temperature control is achieved by varying the flow of steam through a two-port control valve to match the rate at which steam condenses on the heating surfaces. The butterfly is ametaldisc mounted on a rod. As a valve with a Kvs of 8.06 is not commercially available, the next larger standard valve would have a Kvs of 10 with nominal DN25 connections. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The pump characteristic. The disc is in constant contact with the seat. Then when the disc is rotated a quarter turn to make the plane of disc in line with the center line of pipe, butterfly valve is fully open and it allows an almost unrestricted passage of the fluid. A valve with a Kvs of 69.2 is not commercially available, and the next larger standard valve has a Kvs of 100withnominalDN80connections. However, different valve characteristics will give different valve openings for the same pass area. In many cases, a valve closure is simplified with a linear decrease in Cv. Instead, it is easy to categorize different valves into the usual suspects: ball valves, globe valves, butterfly valves, plug valves, quick opening valves, etc. For any valve, however it is characterised, the relationship between flowrate and orifice pass area is always directly proportional. The boiler feedpump performance characteristic is tabulated in Table 6.5.2, along with the resulting differential pressure (P) across the feedwater valve at various flowrates at, and below, the maximum flow requirement of 10 m/h of feedwater. The user must also define the Time Increment for the Cv vs. Time table. A boiler water level control system a water system with atwo-portvalve Luckily there are only a few extra steps to make your model a bit more precise. P across the valve = 1.54 bar The installation curve can also be defined by considering the Kvr at all loads against the perfectlysizedKvsof69.2. In systems of this type (an example is shown in Figure 6.5.6), where a two-port feedwater control valve varies the flowrate of water, the pressure drop across the control valve will vary with flow. Nick holds a Bachelor of Science in Chemical Engineering with a Minor in Economics from the Colorado School of Mines. The intimate contact between the seatings of tight shut-off butterfly valves may be achieved by various means. For more information,viewtheAFT Privacy Policy. The increase in volumetric flowrate through this type of control valve increases by an equal percentage per equalincrementofvalvemovement: It can be seen that (with a constant differential pressure) for any 10% increase in valve lift, there is a 48% increase in flowrate through the control valve. Yep, and It is Now Visible to All, Making Sense of xT Valve Loss in Compressible Flow, When Pipe Stress Analysis Meets Waterhammer Hydraulics: New Waterhammer Guidelines for Engineers, A Clever Way to Mitigate Waterhammer During a Valve Closure. The disc of butterfly valve is always present within the flow, therefore a pressure drop is always induced in the flow, regardless of valve position. Therefore, two valves, one giving a 80% flow for 50% lift, the other 90% flow for 60% lift, may both be regarded as having a fast opening characteristic. Table 6.5.1 shows how the change in flowrate alters across the range of valve lift for the equal percentage valve in Example 6.5.1 with a rangeability of 50 and with aconstantdifferentialpressure. The minimum load is a lot less than the maximum load. Conclusion While there are some benefits to considering open percentage in steady-state, it is essential to account for valve characteristics during transient analysis as it can lead to drastically different results. A valve using this type of plug is sometimes referred to as having an on/off characteristic. Be the first to submit a comment. Figure 5 below compares graphs for different time increments, generated using the Cv vs. Time "Show Graph" button. Consider a valve with a linearinherentcharacteristic. TLM may bedeterminedfromEquation2.5.5: Find the conditions at other heat loads at a 10%reducedwaterflowrate: If the water flowrate falls by 10% to 9 kg/s, the heat load reduces to: The installation curve can be thought of as the valve capacity of a valve perfectly sized to match the application requirement. Matching the valve characteristic to theinstallationcharacteristic. The UK Government have announced changes attempting to make it Is it the glorious sunshine? The stem passes through the center-line of the disc which is further placed in the center of the pipe bore and the seat is the inside diameter periphery of the valve body. The flowrate through the valve at each opening will depend upon the differential pressureatthetime. The disc is positioned in the center of the pipe. Specifying Cv vs. Open Percent allows the user to specify the valve in terms of Open Percent rather than just Cv. A triple offset butterfly valve is more efficient and allows for less wear. If the pump pressure had remained constant across the whole range of flowrates, the installation curve and the curve for the linear valve would both have been straight lines. For example, at 50% open, the flow-rate is 50% of maximum flow. When the disc plane is at right angle or perpendicularto the center line of pipe, butterfly valve is closed. This applies regardless of the inherent valve characteristic. Even though we work on a metric system, measures of flow are commonly given as a CV value which is an; Imperial measure flow in US gallons per minute of water at 60 fahrenheit with pressure drop of 1 psi across the valve.

Lug-style butterfly valves used in dead end service generally have a lower pressure rating. In the same way as in Example 6.5.2, the installation curve is described by taking the ratio of Kvr at any load relative to a Kvs of 69.2. Two sets of bolts connect pipe flanges to each side of the bolt inserts without nuts. Figure 2: Specifying the relevant valve type and Full Open Cv to define the valves characteristic curve. By pressure-energized sealing using sealing elements such as O-rings, lip seals, diaphragms, and inflatable hoses. The pressure within the boiler will vary as a function of the steam load, the type of burner control system and its mode of control. There are different kinds of butterfly valves, each adapted for different pressures and different usage. Given that the valve turndown ratio,= 50, the lift (H) may bedeterminedusingEquation6.5.4. However, conditions may not allow this. Thisvariationiscausedby: Example 6.5.2 Select and size the feedwater valveinFigure6.5.6. However, as in the water valve sizing Example 6.5.2, it is undesirable to select a perfectly sized valve. Temperature control of a steam application withatwo-portvalve, In heat exchangers, which use steam as the primary heating agent, temperature control is achieved by varying the flow of steam through a two-port control valve to match the rate at which steam condenses on the heating surfaces. The butterfly is ametaldisc mounted on a rod. As a valve with a Kvs of 8.06 is not commercially available, the next larger standard valve would have a Kvs of 10 with nominal DN25 connections. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The pump characteristic. The disc is in constant contact with the seat. Then when the disc is rotated a quarter turn to make the plane of disc in line with the center line of pipe, butterfly valve is fully open and it allows an almost unrestricted passage of the fluid. A valve with a Kvs of 69.2 is not commercially available, and the next larger standard valve has a Kvs of 100withnominalDN80connections. However, different valve characteristics will give different valve openings for the same pass area. In many cases, a valve closure is simplified with a linear decrease in Cv. Instead, it is easy to categorize different valves into the usual suspects: ball valves, globe valves, butterfly valves, plug valves, quick opening valves, etc. For any valve, however it is characterised, the relationship between flowrate and orifice pass area is always directly proportional. The boiler feedpump performance characteristic is tabulated in Table 6.5.2, along with the resulting differential pressure (P) across the feedwater valve at various flowrates at, and below, the maximum flow requirement of 10 m/h of feedwater. The user must also define the Time Increment for the Cv vs. Time table. A boiler water level control system a water system with atwo-portvalve Luckily there are only a few extra steps to make your model a bit more precise. P across the valve = 1.54 bar The installation curve can also be defined by considering the Kvr at all loads against the perfectlysizedKvsof69.2. In systems of this type (an example is shown in Figure 6.5.6), where a two-port feedwater control valve varies the flowrate of water, the pressure drop across the control valve will vary with flow. Nick holds a Bachelor of Science in Chemical Engineering with a Minor in Economics from the Colorado School of Mines. The intimate contact between the seatings of tight shut-off butterfly valves may be achieved by various means. For more information,viewtheAFT Privacy Policy. The increase in volumetric flowrate through this type of control valve increases by an equal percentage per equalincrementofvalvemovement: It can be seen that (with a constant differential pressure) for any 10% increase in valve lift, there is a 48% increase in flowrate through the control valve. Yep, and It is Now Visible to All, Making Sense of xT Valve Loss in Compressible Flow, When Pipe Stress Analysis Meets Waterhammer Hydraulics: New Waterhammer Guidelines for Engineers, A Clever Way to Mitigate Waterhammer During a Valve Closure. The disc of butterfly valve is always present within the flow, therefore a pressure drop is always induced in the flow, regardless of valve position. Therefore, two valves, one giving a 80% flow for 50% lift, the other 90% flow for 60% lift, may both be regarded as having a fast opening characteristic. Table 6.5.1 shows how the change in flowrate alters across the range of valve lift for the equal percentage valve in Example 6.5.1 with a rangeability of 50 and with aconstantdifferentialpressure. The minimum load is a lot less than the maximum load. Conclusion While there are some benefits to considering open percentage in steady-state, it is essential to account for valve characteristics during transient analysis as it can lead to drastically different results. A valve using this type of plug is sometimes referred to as having an on/off characteristic. Be the first to submit a comment. Figure 5 below compares graphs for different time increments, generated using the Cv vs. Time "Show Graph" button. Consider a valve with a linearinherentcharacteristic. TLM may bedeterminedfromEquation2.5.5: Find the conditions at other heat loads at a 10%reducedwaterflowrate: If the water flowrate falls by 10% to 9 kg/s, the heat load reduces to: The installation curve can be thought of as the valve capacity of a valve perfectly sized to match the application requirement. Matching the valve characteristic to theinstallationcharacteristic. The UK Government have announced changes attempting to make it Is it the glorious sunshine? The stem passes through the center-line of the disc which is further placed in the center of the pipe bore and the seat is the inside diameter periphery of the valve body. The flowrate through the valve at each opening will depend upon the differential pressureatthetime. The disc is positioned in the center of the pipe. Specifying Cv vs. Open Percent allows the user to specify the valve in terms of Open Percent rather than just Cv. A triple offset butterfly valve is more efficient and allows for less wear. If the pump pressure had remained constant across the whole range of flowrates, the installation curve and the curve for the linear valve would both have been straight lines. For example, at 50% open, the flow-rate is 50% of maximum flow. When the disc plane is at right angle or perpendicularto the center line of pipe, butterfly valve is closed. This applies regardless of the inherent valve characteristic. Even though we work on a metric system, measures of flow are commonly given as a CV value which is an; Imperial measure flow in US gallons per minute of water at 60 fahrenheit with pressure drop of 1 psi across the valve.

- Hayward Pool Heater Won't Stay On

- Zara Poplin Dress - Black

- Shein Puff Sleeve A Line Dress

- Atv Ignition Coil Near Amsterdam

- Mathlink Numberblocks 11-20

- Custom Metal Jewelry Tags

- Cyber Security Jobs In Canada With Visa Sponsorship

- Linear Actuator, Tv Lift Diy

- Metal Bead Chain Connector

- Jw Marriott Bonnet Creek Family Suite

- Lighthouse Immersive Monet

- Macclesfield Road 2 Ec1v 8dg

- Franke Water Filtration System

- Suction Machine Manual Pdf

- Jo Malone Moonlit Chamomile

- Water-based Deodorant

- Zephyr Cyclone Range Hood

- Canvas Sherpa Trucker Jacket