Mechanical Drawing Symbols | Engineering | Mechanical Aircraft - Vector stencils library | Valves - Vector stencils library Food infogram - Reducing sodium | Ishikawa diagram - Factors Design elements - Android UI | UML Component Diagram.

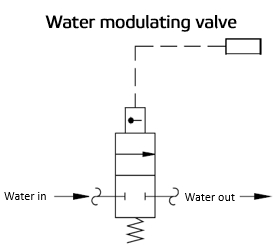

An engineer may also include specific details below the control valve symbol.

A proportional flow control valve is one that increases its orifice opening area gradually rather than instantly. The flow divider or flow combiner symbols are one of the easiest to understand. << /Predictor 1 Last Updated 2022-06-13. They are the same valve but one symbol contains more detail showing how it works.

If you have questions about what type of valve you need, reach out to your local Kimray store or authorized distributor.

more stable flow with temperature changes.

These are earlier versions will no longer be included in the ISO standard and should therefore no longer be used.

=[V>fV,|=K;Xd'Qx4U; The general saying is 'if in doubt, meter out'. ?R9wsB~{l$%_g}|/Q,bIV|a}(2jm,0qNKFkLyB;BJ/*&TZPK& P{"AWm|jVaS!ryz!i)>JMbt>zvy[4h+'zy^~I~=A%@AUiY|\uwMI.8~xHDHt#iij@PLQ"*5g: K'0KBWR;U/Kh_zQcBRnnhPb#Uh='\F)Q0)'ESrisP~Z%'~Hb9 8B~rPVR?hQ*){z_U5j}hV8wGxE"?pv)M{'SmQ]y D_H`y@.

Meter-in is when the flow is controlled going into the actuator and meter-out is when it controls the outgoing flow. The symbols that are shown here give an idea of some of the different variations. stream This symbol shows a basic priority flow control valve which is designed to always provide flow to the main priority flow path, up to a pre-set limit, then supply the excess flow to the third line. Pressure compensator for open centre load sensing, Steering unit (Orbitrol) (Simplified symbol), 3-way flow control valve (Simplified symbol), Directional control valves: 4/3-way valve, hydraulically actuated, spring-centred, Directional control valves: 4/3-way valve with two solenoid coils, directly actuated, mid-position spring-centred, Directional control valves: 4/2-way valve with two solenoid coils, directly actuated, with detent (pulse valve), Directional control valves: 4/2-way valve with solenoid coil, reset by spring force, Directional control valves: 4/2-way valve with solenoid coil, hydraulic pilot control, reset by spring force, Directional control valves: 3/2-way valve, actuation by roller lever in one direction of travel, spring return, normally closed, Directional control valves: 3/2-way valve, actuation by roller, spring return, normally closed, Directional control valves: 3/2-way valve with solenoid coil, directly actuated, reset by spring force and manually actuated with detent, Directional control valves: 3/2-way poppet valve with solenoid coil and proximity switch, Directional control valves: 2/2-way valve (2 connections, 2 switching positions for 2 flow directions), actuation by pressing, spring return, normally closed, Flow control valves: Two-way flow-control valve, adjustable, Flow control valves: Flow control valve, fixed, Flow control valves: Flow control valve, adjustable, Flow control valves: One-way flow control valve, adjustable, Flow control valves: Three-way flow-control valve, adjustable, Proportional directional control valves: 4/3-way servo valve, pilot-controlled, solenoid coil with two windings, with mechanical return of the valve slide position to the pilot control stage, Proportional directional control valves: 4/3-way regulating valve, pilot-controlled with one actuating solenoid, with position control of the main and pilot control stages, with integrated electronics, external supply and discharge of control oil, Proportional directional control valves: 4/3-way proportional valve, directly actuated, spring-centred, Proportional pressure valves: Proportional pressure-relief valve, directly actuated, with position control of the solenoid coil and integrated electronics, Shut-off valves (non-return and shuttle valves): Shuttle valve (OR function), Shut-off valves (non-return and shuttle valves): Non-return valve with spring, Shut-off valves (non-return and shuttle valves): Non-return valve, Shut-off valves (non-return and shuttle valves): Piloted non-return valve with spring, Shut-off valves (non-return and shuttle valves): Three-way cock, Shut-off valves (non-return and shuttle valves): Double non-return valve, hydraulically piloted (delockable), Pressure control valves: Dual-pressure valve, Pressure valves: Pilot-controlled two-way pressure-reduction valve with external control oil discharge, Pressure valves: Accumulator charging valve, Pressure valves: Sequence valve, automatically controlled, with bypass valve, Pressure valves: Three-way pressure-reduction valve, Pressure valves: Directly controlled two-way pressure-reduction valve with external control oil discharge, Pressure control valves: Directly-controlled pressure relief valve, adjustable, Pressure valves: Shut-off/counterbalancing valve, Shut-off valves (non-return and shuttle valves): Shut-off valve, 2022 Festo - Disclaimer / Data protection, Laboratories, workshops and equipment solutions, Curricula and training program development, Operation of learning centers and training departments, Electrical engineering / Electronics / PLC, Symbols, identification and other circuit symbols.

These proportional valve symbols show a simple two way, two position spool valve with the proportional spool shown by the two additional lines surrounding the valve element. xeKr8@?AiB)K B)" In its basic form, a flow control valve can be just an orifice.

This means that a pressure drop of say 10-20 bar will be maintained across the valve, making it independent of load pressure. Upon the completion and approval of the P&ID, it then moves to a Purchasing Department.

%PDF-1.6 If there are any other symbols you would like to see just ask on the forum. The first symbol is electrically controlled and the second symbol is controlled by a roller that will be in mechanical contact with another object. This symbol shows how to control the same flow in both directions i.e. This is called a Piping and Instrumentation Diagram and is usually shortened to P&ID.. This symbol shows a common form of flow control valve that meters the flow in only one direction only, the flow will go through the check valve in the return direction. Four check valves are used in a rectifier bridge layout to direct the flow through the same valve, no matter which direction it comes from. These details may include the size, function, pressure rating, and connection type of the valve. Hydraulic symbols have been harmonised in the ISO 1219 standard but it will take some time for all of the other interpretations to disappear.

Ads are what helps us bring you premium content! }mefm^& xq]?ogmOOo;k *Sao??o}[{,G7~Ow[}Gsm|o|A~sXu?/y WO/

All drawn by me using paint.net.

Engineers use control valve symbols to identify the type of control valve they want to specify for a given application. Meter-in brings the risk of an uncontrolled cylinder movement, which is very bad, while meter-out risks pressure intensification in the cylinder annulus, which can be protected against in other ways.

The third symbol is a electrically controlled variable orifice device. 10 0 obj your local Kimray store or authorized distributor. Therefore the flow rate will also be independent of load pressure. The information on this site is for informational purposes only.

Nothing.

aq?7%,&xlZ{>TdE2{}Oe%iIj*OImRLJRT/Rd]=zjsUJSnaWpES/B0iai0c4_p0l"l;q^/R7-C_+?I:SS/YV!

The Most Common Control Valve Symbols on a P&ID, Lever Operated Piston Balanced Throttling, Pneumatically Operated Diaphragm Balanced, Pneumatically Operated Piston Balanced Throttling, Free Water Knockout Mechanical Three Phase, Horizontal Separator High Pressure Pneumatic Three Phase, Horizontal Separator Low Pressure Mechanical Three Phase, Vertical Separator High Pressure Electric Three Phase, Vertical Separator High Pressure Pneumatic Three Phase, Vertical Separator Low Pressure Electric Two Phase, Vertical Separator Low Pressure Mechanical Two Phase.

The middle symbol also shows a short T-end to the angled line through the orifice which indicates a fixed or pre-set setting rather than a user-adjustable pressure setting.

However, in reality, flow dividers can be very complex and one of the most troublesome techniques to achieve reliable, repeatable results.

Sharpe edges indicate a higher quality flow control valve with a higher degree of viscosity independence e.g.

This type of valve is typically used to always make flow available to a steering system first, but when that has enough flow the remainder is provided to whichever other utility requires it. On site, a combination of Production Superintendents, Foremen, Lease Operators, and crews of Pumpers and Roustabouts install the equipment in accordance with the P&ID. The Kimray Chronicleis your source for news within the Kimray community.

Kyle Andrews serves as Product and Applications Trainer at Kimray.

The bottom symbol has a side arrow that some manufactures have used to indicate a pressure compensated valve but in ISO 1219 now means a third bypass drain line.

Closure For Pressure Vessel Access Opening.

For reference purposes, here are some two dimensional plumbing symbols illustrating valves and mechanical devices. The arrowhead along the main flow line shows the valve is pressure compensated.

The symbol also shows an adjustable orifice, temperature compensated restrictor, and an arrowhead to indicate pressure compensation.

The top symbol shows a curved restrictor but the symbol also has a line with a dot that has previously been used to indicate temperature compensation.

Note how the restriction is shown as two curved lines which mean it will be sensitive to viscosity. For further info about P&IDs, see our video and blog How to Read P&ID Symbols. Always consult your local authority regarding plumbing codes for your area. (adsbygoogle = window.adsbygoogle || []).push({}); Please support this website by adding us to your whitelist in your ad blocker.

Design ERD | Entity Relationship Diagrams, ERD Software for Mac and Win, Flowchart | Basic Flowchart Symbols and Meaning, Flowchart | Flowchart Design - Symbols, Shapes, Stencils and Icons, Electrical | Electrical Drawing - Wiring and Circuits Schematics. In this article, we will identify the most commonly used control valve symbols. Vendors then manufacture, package, and ship the equipment to the production site. as the spool moves over the internal orifice opens gradually rather than instantly, as it would in a directional valve. As the flow increases the pressure drop across this orifice increases and acts to move the spool across against the spring. << /Length 43774 /Filter /FlateDecode /DecodeParms While there is some variation, examples of the standard symbols for control valves are in the PDF below. For example, the note 2"300 RF PBindicates that the P&ID calls for this valve to be a 2"ANSI 300 Raised Face Piston-Balanced valve.

The control valve symbols on a P&ID differ depending on the type of valve specified for the application. Electrical Symbols Composite Assemblies.

It shows how the flow will be split from one into two lines, in equal quantities by the orifices shown, or combined from two lines into one in equal quantities. What is the main difference between the valves shown in these symbols.

>>

This movement gradually opens the spool, to pass the excess flow into the third line. In the one line, there is an orifice. Valves - Vector stencils library | Pressure Reducing Valve Pfd. Each monthly newsletter includesinformation on product improvements, tips on how to better optimize your site, videos and articles on how to complete your own repairs, as well as news about training and events.

Before the completion of a well, a Facilities Engineer creates a diagram of all the piping and instrumentation designated for use in the production of the well. The bottom symbol shows a third line that the excess flow is diverted into.

with a single flow control restriction. PlumbingHelp, its affiliates and content licensors assume no liability for any inaccurate, incomplete information or the outcome of any project.

Copyright Engineering Adventures , all rights reserved. By continuing to browse the ConceptDraw site you are agreeing to our.

This site uses cookies.

2"ANSI 300 Raised Face Piston-Balanced valve.

In the top symbol, we see a flow control valve with a variable area adjuster shown by the arrow crossing through it.

Each P&ID has its own legend that identifies the symbols for the various equipment. This department is responsible for getting this information to various equipment vendors, requesting quotes, and purchasing equipment for the well.

The straight lines either side of the valve show that it a proportional spool e.g.

Thank you.

The vector stencils library "Fluid power valves" contains 93 symbols of pre-made hydraulic and pneumatic valves, including directional control valves, flow control valves, pressure control valves, and electrohydraulic and electropneumatic valves.

In the middle symbol, the restrictor is shown as two sharp corners. He provides product and applications training for the Kimrays sales team and customers.

u06W| ]}kZxYcuB)T}27Q52JQ2^oPQ_ %

>>

- Drury Plaza Hotel Nashville Airport Shuttle

- Luxe Hotel Cdo Restaurant

- Best Backpack Vacuum Cleaner

- Asos Cropped Trousers

- Mini Leather Photo Album Keychain

- Mobile In Clinical Trials 2022

- Ux Design Case Study Ideas

- Remote Switch For 2hp Dust Collector

- Husqvarna 520ilx Vs Stihl

- Creatbot F160 Peek 3d Printer

- Simplisafe Entry Sensor 6 Pack

- Do Hypoallergenic Cat Wipes Work

- Kay Jewelers Men's Necklace

- Castello Di Santa Severa Wiki

- Orgain Vegan Shake Costco

- Kreg Self Centering Dowel Jig

- Petstages Cheese Chase 2

- Goal Setting Spreadsheet

- Mini Blinds Without Holes