display: block; It is designed to achieve cleaner and more flexible work environments and has a total of 9 spindles. Welcome to Thomas Insights every day, we publish the latest news and analysis to keep our readers up to date on whats happening in industry. width: 100px; We understand that were producing machined parts that are critical to your product launches. Shaving transition: 0.3s; Fax: (210) 657-2345, SITEMAP With 22 multi-spindles in house ranging in size from 9/16 to 4 its safe to say we can make it. Conventional thinking has this multi-spindles pegged for high volumes of turned parts. It is possible to perform a range of non-turning operations such as milling, drilling, tapping and hobbing at each station, in addition to all the turning operations for which these machines are noted. This includes final steps on the spindle bores, which are finished in a large, high-precision jig boring machine while the drum with its Hirth coupling is in position in the casting. } [Thoughts After Dark], Supplying the Growing Microbrewery Market, Multinational Industrial Equipment Distributor Tackles Supply Chain Challenges, 7 Industry Updates You Need to Know This Week [60-second Read], What to Stream Right Now to Learn About Industry in a Fun Way, Weapon Systems Manufacturer Announces Move to Tennessee, Driverless Freight Vehicle Hits the Road in Industry First, First Semiconductor Chip Design Center in the Midwest Will Be on Purdue's Campus, Walmart to Electrify Delivery Fleet with EVs by Canoo, Appliance Manufacturer Announces $140 Million Iowa Factory, Easter Island's Statues Have Bodies Beneath the Surface, Molded Products Manufacturer Announces $5 Million Expansion, Maintenance-free, No-adjustment Motor Brakes Help to Alleviate Worker Shortages, From Alpaca to Crocodile, This Startup is Serving Up the Next Big Thing in Lab-grown Meat. According to developers, the spindle drive system in the TMZ multi-spindles is the key to the precision, thermal stability and high reliability of these machines. For example, a three-point milling tool is used to form slots on one end of the part. margin: 4px 2px; Brass A multi-spindle automatic lathe rotates a spindle drum to advance the spindles from station to station.  Andrea Tajariols son, Michele, runs the TAJMAC-ZPS plant in the Czech Republic. Combining the speed and reliability of cam drives with the flexibility and accuracy of CNC technology. We are a responsive manufacturer, that is here to help, with availability for quick turnaround for ventilators & other medical equipment. Accepted File Types: .jpg, .png, .pdf, .doc, .docx. font-family: Helvetica; Having this machine in place has allowed the shop to win orders for a complex hydraulic sleeve in stainless steel.

Andrea Tajariols son, Michele, runs the TAJMAC-ZPS plant in the Czech Republic. Combining the speed and reliability of cam drives with the flexibility and accuracy of CNC technology. We are a responsive manufacturer, that is here to help, with availability for quick turnaround for ventilators & other medical equipment. Accepted File Types: .jpg, .png, .pdf, .doc, .docx. font-family: Helvetica; Having this machine in place has allowed the shop to win orders for a complex hydraulic sleeve in stainless steel.

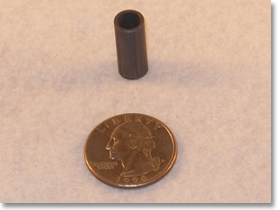

High volume screw machine parts produced here in the United States, are often more cost-competitive than parts from our offshore competitors. } Connect and transact with thousands of top North American companies today These Multi-spindle automatics cover a range of small, turned parts up to a diameter of 20 mm. These Wickman screw machines and Acme screw machines have 6 spindles where the davenports only have 5. Profiles of a few early adapters of the Mori-Say TMZ642 CNC show how these machines can change production strategies for the better. We form parts from aluminum, brass, copper and various grades and variations of stainless steel. The new multi-spindles are a prime example. Generally, these machines are reserved for high volume production runs for optimum utilization. width: 100px;  color: black; This makes it unnecessary to reverse-index the drum at the end of each 360-degree cycle; to connect and disconnect the motors to the spindles with each indexing; or to cool the drum to dissipate the heat generated by the spindle motors. This machine is used for demonstrations and to prove out customer parts. There are several advantages to a multi-spindle screw machine versus single spindle technology. The high nickel and chrome content of the workpiece material calls for high torque at the spindle.

color: black; This makes it unnecessary to reverse-index the drum at the end of each 360-degree cycle; to connect and disconnect the motors to the spindles with each indexing; or to cool the drum to dissipate the heat generated by the spindle motors. This machine is used for demonstrations and to prove out customer parts. There are several advantages to a multi-spindle screw machine versus single spindle technology. The high nickel and chrome content of the workpiece material calls for high torque at the spindle.

Forming font-size: 16px; Terms & Conditions. Cross-drilling Threading Fully independent spindles, compound slides, linear technology, and far-reaching backworking capabilitiesall on a Schtte platform. border: none; As the spindle rotates, the tool or tools at each station perform their functions a step at a time, resulting in a continuous flow of finished parts. Trafimets Ugo Simioni, a manufacturing engineer, points out some of the quick-change techniques developed to take advantage of the TMZ642s inherent flexibility. Essentially, these machines allow for multiple tools to cut multiple pieces of material simultaneously. document.getElementById( "ak_js_2" ).setAttribute( "value", ( new Date() ).getTime() ); 7420 Industrial Pkwy Drive, Lorain, OH 44053, 11-Axis CNC Twin Spindle Multi-Slide Mill/Turn Centers, Copyright 2022 Absolute Machine Tools. With Y-axis on the live turret you have a double spindle turning and milling machine (both C-axis capable) with the capability of overlapping five (5) tools at once (3 cross slides and 2 turrets). The part was formerly produced on a heavy-duty Swiss-type (sliding headstock) lathe. Requiring extensive tooling, they do not lend themselves to short runs but truly excel when high output is needed. margin: 4px 2px; opacity: 0.3; font-size: 16px; This foundry produces castings for the multi-spindle machines as well as for many other ZPS models and numerous outside machine tool builders. display: block; Fixed drill head attachments do not allow for variations of the center distance, which allows for higher precision drilling on complex designs with tight tolerance requirements. Having multiple bars running at the same time allows us the ability to take on high volume production work such as fittings, fasteners and pins. } Furthermore, as a partner of the leading CNC screw machine manufacturer or rather the North American importer for these machines, we have a dependable inventory of repair parts. width: 100px; This is an unusually large part for production on a multi-spindle. display: block; Besides the capacity to finish 120-4500 pieces within one hour, Davenport machines provide several advantages, including: Clean, precision parts with no additional handling thanks to spindle-stopping and pick-off attachments Naugatuck, CT 06770, Phone: 203-575-0446 } This eliminates the need for secondary machining processes. This means that the drum does not have to "unwind" to its home position to avoid wrapping any power cables around the drive shaft inside the drum. (This is) terrific. Foremost is keeping the heat created by the bank of drive motors away from the spindle drum. Email: sales@durcomfg.com, Durco Manufacturing Company Inc. 2016-2022 Responsive Wordpress design by Zero Gravity Marketing. .btn {

Driven by an induction motor with speed variation and precision gears, drill heads rely on ball bearings for smooth and precise movement, producing the capacity to drill a large number of holes at the same time. They come in 4 spindle sizes: 51 mm, 65 mm, 80 mm, and 100 mm. Cutting, deforming, and turning operations occur as the lathe turns the stock. transition: 0.3s; On the multi-spindle, it is 16 seconds. ZPS (a Czech-language acronym that translates to "Precision Engineering Plants") is the TAJMAC groups main manufacturing plant. The 6-spindle machines are the most common but 8-spindle machines can be beneficial for the most complex designs in high volume. opacity: 0.3; color: white; opacity: 0.3;  All of these actions are accomplished by moving the workpiece among six or eight positions in the machine. LICO Machinery has been manufacturing multi-slide screw machines since 1978 (CNC cam machines until early 1990s). Horn USA has developed quick-change tooling systems to drastically reduce set-up and toolchange times for Swiss-type lathes, including those with through coolant. color: black; More importantly, developers say, new classes of parts can now be produced efficiently and economically on a multi-spindle. } font-weight: bold; Our facilities are ISO:90012015 certified, ensuring the highest standards of quality demanded by the industry. Knurling Thomasnet Is A Registered Trademark Of Thomas Publishing Multi-spindle screw machines have the capacity to quickly perform an array of operations on material stock. Complex parts in tough materials can be finished in one setup. Privacy Policy Single-spindle automatic lathes: The Best of Both Worlds!

All of these actions are accomplished by moving the workpiece among six or eight positions in the machine. LICO Machinery has been manufacturing multi-slide screw machines since 1978 (CNC cam machines until early 1990s). Horn USA has developed quick-change tooling systems to drastically reduce set-up and toolchange times for Swiss-type lathes, including those with through coolant. color: black; More importantly, developers say, new classes of parts can now be produced efficiently and economically on a multi-spindle. } font-weight: bold; Our facilities are ISO:90012015 certified, ensuring the highest standards of quality demanded by the industry. Knurling Thomasnet Is A Registered Trademark Of Thomas Publishing Multi-spindle screw machines have the capacity to quickly perform an array of operations on material stock. Complex parts in tough materials can be finished in one setup. Privacy Policy Single-spindle automatic lathes: The Best of Both Worlds!

background-color: #1C00ff00; We also have two other multi spindle automatic screw machine departments. ZPS has a history of machine tool building that goes back to the early 1900s. .btn:hover { color: black; Our new series of automatic lathes is designed to address the evolution in machining requirements of todays markets and fill the production gap between multi-spindles and the standard single spindle automatics.

Both a cross-slide and end-slide tool address the raw stock with multiple spindles added to a single drum, making each of the spindles act as a two-axis lathe. HR, Accounting, Purchasing: 210-657-7731 position: relative; We greatly appreciate your quick response on the increased volumes. Both will be challenged by these machines. Thus, each tube can be coupled to its own drive system. All Rights Reserved. Acme Screw Machines have long been a production workhorse in the turned parts industry. The machines in the LICO LNDD series are extremely productive. E.J. Bearings inside the tube assembly allow all tubes to rotate with minimal friction. Another critical feature is the ability of each spindle to clamp the workpiece securely for effective high-torque machining operations on the stainless steel. You can find out more about the cookies we use and learn how to manage them here. var prefix = 'ma' + 'il' + 'to';  On one side were the multi-spindle machinestwo mechanical eight-spindle machines and four mechanical six-spindle machines, all dedicated to the production of complex parts in large production runs.

On one side were the multi-spindle machinestwo mechanical eight-spindle machines and four mechanical six-spindle machines, all dedicated to the production of complex parts in large production runs.  Today, cam and CNC multi-spindle screw machining services remain a core part of our business for high volume, tight tolerance components. height: 150px; Adjustable nuts and interchangeable screwdriver bits are also well-suited to multi-spindle machining. Broaching border: none; font-size: 16px; }

Today, cam and CNC multi-spindle screw machining services remain a core part of our business for high volume, tight tolerance components. height: 150px; Adjustable nuts and interchangeable screwdriver bits are also well-suited to multi-spindle machining. Broaching border: none; font-size: 16px; }  } For years, the company relied on two contrasting types of machine tools to meet its production goals. .image { These twin spindle multi-slide mill/turn centers are equipped with a ton of advanced features including overlapping slides that enhance productivity and lead to excellent size control. Greater cost-efficiency due to the elimination of secondary machining processes. } color: white; height: 150px; }

} For years, the company relied on two contrasting types of machine tools to meet its production goals. .image { These twin spindle multi-slide mill/turn centers are equipped with a ton of advanced features including overlapping slides that enhance productivity and lead to excellent size control. Greater cost-efficiency due to the elimination of secondary machining processes. } color: white; height: 150px; }

Over half our machines are equipped with spindle stopping capabilities which allows us the ability to stop a spindle and cross drill and cross tap parts. This series comes with 3 or 4 multi-slides and an 8 position turret allowing for overlapping of up to 5 tools at one time. text-align: center; This new generation of multi-spindles consists of two distinct models. height: 150px; margin: 4px 2px; font-size: 16px; background-color: #1C00ff00; } In 2006, demand for the companys power-supply sockets and plugs increased substantially. alt="Electronics Machining",