Metal Roof Trims: What Kind of Metal Roofing Dont Forget the Metal Roofing Trim to Go with How Metal Roofing Prices In Hawaii Compare.

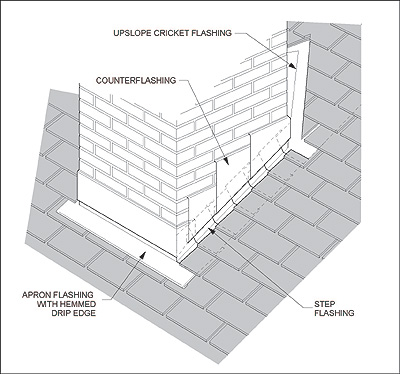

We have tried angling the roof shingles away from the joint, placing the chimneys at the roof ridge, and even building steps into the sides of the chimney to help throw off water.  Flashing keeps things sealed while allowing for this movement. One final point:if water cant get in, then mold growth will be inhibited as well. Install metal flashing over the exposed area and then install drip edges that follow the same steps as step one.

Flashing keeps things sealed while allowing for this movement. One final point:if water cant get in, then mold growth will be inhibited as well. Install metal flashing over the exposed area and then install drip edges that follow the same steps as step one.  Building codes establish minimum requirements, but products must also be installed in accordance with manufacturers instructions. 3, 15. It involves applying weather resistant barrier sheeting, and screwing or nailing the sheeting in place so that it forms an airtight seal between the wall and your roof. Roof flashing is time-consuming and needs much effort, but it isnt difficult. A specialized type of wall flashing issill flashingor asill pan;it is concealed under windows or door thresholds to prevent moisture leakage. (IRC 2018 Section R903.2 Flashing, Section R905.2.8.3 Sidewall flashing, R908.6 Flashings for reroofing). How to Install Flashing at the Transition of a Wall to a Lower Roof. Generally, it will be one of two directions: overhanging or downspout. Nghe is a marketing professional with more than 14 years of experience in various environments and industries. Set the very first shingle above the starting strip and kickout flashing, and fix it with roofing cement and two nails. Through-wall flashingspans the thickness of the wall. Figure 5 shows flashing at a roof-wall intersection with a CMU wall. After all, a drafty structure isnt very energy efficient. Exposure to salt air and acid rain can cause corrosion while excessive heat, heavy snow, and scouring winds can physically change the shape of the flashing.

Building codes establish minimum requirements, but products must also be installed in accordance with manufacturers instructions. 3, 15. It involves applying weather resistant barrier sheeting, and screwing or nailing the sheeting in place so that it forms an airtight seal between the wall and your roof. Roof flashing is time-consuming and needs much effort, but it isnt difficult. A specialized type of wall flashing issill flashingor asill pan;it is concealed under windows or door thresholds to prevent moisture leakage. (IRC 2018 Section R903.2 Flashing, Section R905.2.8.3 Sidewall flashing, R908.6 Flashings for reroofing). How to Install Flashing at the Transition of a Wall to a Lower Roof. Generally, it will be one of two directions: overhanging or downspout. Nghe is a marketing professional with more than 14 years of experience in various environments and industries. Set the very first shingle above the starting strip and kickout flashing, and fix it with roofing cement and two nails. Through-wall flashingspans the thickness of the wall. Figure 5 shows flashing at a roof-wall intersection with a CMU wall. After all, a drafty structure isnt very energy efficient. Exposure to salt air and acid rain can cause corrosion while excessive heat, heavy snow, and scouring winds can physically change the shape of the flashing.  Flashings shall be installed in a manner that prevents moisture from entering the wall and roof through joints in copings, through moisture permeable materials and at intersections with parapet walls and other penetrations through the roof plane. The Compliance tab contains both program and code information.

Flashings shall be installed in a manner that prevents moisture from entering the wall and roof through joints in copings, through moisture permeable materials and at intersections with parapet walls and other penetrations through the roof plane. The Compliance tab contains both program and code information.

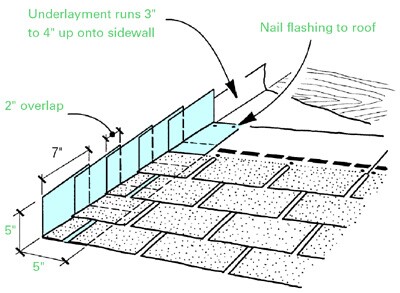

Figures 2 and 3 show a front view of integration of a new strip of fully adhered air control transition membrane, new step or continuous flashing, new roof underlayment, and new cladding with the existing house wrap and siding.

Without roof flashing, the wall will suffer from great damage structurally due to leakage. If the flashing becomes damaged, a leak will be the result. Cap flashing,also known as adrip capis installed above the windows and doors. In addition, any option in 2009 IRC Section R905.13 is permitted to be used to meet either Item 3.3 or 3.4. These customize cuttings of the flashing and shingles will curve over the roofs top, forming a curved arrangement that will keep the joint impermeable. Section R703.8 (R703.8.5 in 2015, 2018, and 2021 IRC) Flashing.

Its pretty self-explanatory where this is used. The fundamental principle of water management is to shed water by layering materials in such a way that water is directed down, out, and away from the building. The metal flashing pieces are bent at a right angle with half of the flashing against the wall and the other half interwoven with or underneath the shingles of the abutting roof. 3.4 In 2009 IECC Climate Zones 5 & higher, self-adhering polymer-modified bituminous membrane over sheathing at eaves from the edge of the roof line to > 2 ft. up roof deck from the interior plane of the exterior wall. Be safe and all the best. So, even where the IRC does not require additional measures, proper installation is more critical in hurricane-prone regions. Space the fasteners between 12 and 24 inches apart. Make sure you follow them properly and accordingly. Base flashing against a vertical sidewall shall be continuous or step flashing and shall be not less than 4 inches (102 mm) in height and 4 inches (102 mm) in width and shall direct water away from the vertical sidewall onto the roof or into the gutter. Guide describing how and where to install flashings in order to weatherproof a roof. Its end needs to be cut, angled, and folded to fit the roof side, and meet the end wall and eave.  Concrete is poured around the perimeter of a home to form both the foundation and footers.

Concrete is poured around the perimeter of a home to form both the foundation and footers.

The IRC does not have additional requirements for roof-wall flashing in hurricane-prone regions or other high-wind areas.

Using hex head screws makes your flashing more impermeable and keeps your structure safe from water damage. Flashing a metal roof may seem daunting at first glance but is relatively painless with these three steps. 09), Water Management System Builder Requirements, 3. Flashing is the most underrated of building enclosure components and arguably one of the most important. Water and mold damage is the most commonly seen problem in any structure. Step 2: Flash the valley and hips (when applicable) Flash the location of any valleys and hips on your roof, including areas where a valley may be exposed due to a dormer or chimney. Where roofs intersect walls is a critical point for flashing to prevent water leaks and damage. They are relatively easy to install if you have some basic roofing knowledge and experience. It is installed to direct water run-off away from the adjoining wall and usually into a gutter. The environment plays the main role in flashing and roof failure. For exact code language, refer to the applicable code, which may require purchase from the publisher. Extend at least 2 inches above the future step flashing.

Using hex head screws makes your flashing more impermeable and keeps your structure safe from water damage. Flashing a metal roof may seem daunting at first glance but is relatively painless with these three steps. 09), Water Management System Builder Requirements, 3. Flashing is the most underrated of building enclosure components and arguably one of the most important. Water and mold damage is the most commonly seen problem in any structure. Step 2: Flash the valley and hips (when applicable) Flash the location of any valleys and hips on your roof, including areas where a valley may be exposed due to a dormer or chimney. Where roofs intersect walls is a critical point for flashing to prevent water leaks and damage. They are relatively easy to install if you have some basic roofing knowledge and experience. It is installed to direct water run-off away from the adjoining wall and usually into a gutter. The environment plays the main role in flashing and roof failure. For exact code language, refer to the applicable code, which may require purchase from the publisher. Extend at least 2 inches above the future step flashing.

Flashing should be integrated with roof and wall drainage planes, such as house wrap or building paper, in shingle fashion where the top layer of the weather-resistant barrier (WRB) or flashing laps over the bottom layer to prevent water draining behind the bottom layer. Its main job is to deflect water away from the seams or joints and in roof valleys where water runoff is concentrated. Follow the minimum requirements of the current adopted local building code. The concrete forms what will become the walls of your house. Flashing can be made of several kinds of materials, but the most flexible and durable are made of metal.  If thats the case, read this quick primer on how to install the following metal roof flashings on your home. The Difference Between Post-Frame and Pre-Engineered Steel Buildings, HOW TO USE GALVALUME FOR YOUR METAL ROOF, Malleable metals such as aluminum, zinc, and stainless steel, Open valleys where shingles or slate must overlap the flashing by at least six inches, Equal slopes with unequal water flow require 1 inch baffles to prevent higher velocity water from forcing its way past the opposite edge of valley flashing, Closed valleys where the intersection roof must have the same slope so shingle-butts lines up at the intersection. These are sized to handle the larger volumes of water runoff that may be concentrated along the wall in rain storms. In cold climates (zones 5 and higher), install self-adhered ice and water shield membrane over the roof sheathing at the eaves from the edge of the roof line to at least 2 feet up the roof deck from the interior plane of the exterior wall. Assessments by FEMA after hurricanes commonly find that water intrusion and structural building failures are due to improper installation of building components. Extend it to the existing wall and over the transition membrane; the underlayment should wrap up the sidewall at least 8 inches. Flashing is also used on any junctures where different materials come together, such as between different types of roofing, or at the top of exterior walls.

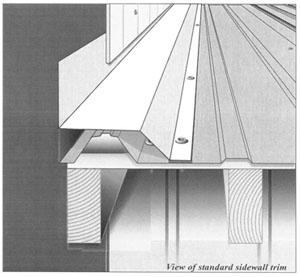

If thats the case, read this quick primer on how to install the following metal roof flashings on your home. The Difference Between Post-Frame and Pre-Engineered Steel Buildings, HOW TO USE GALVALUME FOR YOUR METAL ROOF, Malleable metals such as aluminum, zinc, and stainless steel, Open valleys where shingles or slate must overlap the flashing by at least six inches, Equal slopes with unequal water flow require 1 inch baffles to prevent higher velocity water from forcing its way past the opposite edge of valley flashing, Closed valleys where the intersection roof must have the same slope so shingle-butts lines up at the intersection. These are sized to handle the larger volumes of water runoff that may be concentrated along the wall in rain storms. In cold climates (zones 5 and higher), install self-adhered ice and water shield membrane over the roof sheathing at the eaves from the edge of the roof line to at least 2 feet up the roof deck from the interior plane of the exterior wall. Assessments by FEMA after hurricanes commonly find that water intrusion and structural building failures are due to improper installation of building components. Extend it to the existing wall and over the transition membrane; the underlayment should wrap up the sidewall at least 8 inches. Flashing is also used on any junctures where different materials come together, such as between different types of roofing, or at the top of exterior walls.  Continuous flashing shall be installed in place of step flashing for metal and rubber membrane roofs. Its used at windows, areas of structural support, and other interruptions in the wall. per ft. away from the home for at least 5 ft., with Group I Soils (as defined in Footnote 8) covering the membrane to within 3 in. Flashing is typically done on brick walls. Kloeckner Metals Hawaiiis Hawaiis most trusted metal roofing manufacturer.

Continuous flashing shall be installed in place of step flashing for metal and rubber membrane roofs. Its used at windows, areas of structural support, and other interruptions in the wall. per ft. away from the home for at least 5 ft., with Group I Soils (as defined in Footnote 8) covering the membrane to within 3 in. Flashing is typically done on brick walls. Kloeckner Metals Hawaiiis Hawaiis most trusted metal roofing manufacturer.

Unfortunately, your browser doesn't support those technologies. Roof step flashing must be effectively integrated with diverters known as kick-out flashing to effectively direct water to the gutters and avoid water damage.

Note Figures 4 and 5 are from the Insurance Institute for Building and Home Safety (IBHS) Fortified Home program which recommends that the metal drip edge be installed over the underlayment on roofs in hurricane and high-wind-prone regions.  Membranes are one piece and can simplify installation around roof projections.

Membranes are one piece and can simplify installation around roof projections.

You probably agree that a leaky roof is a bad thing. Metal roof flashing does more than just seal joints and protect your home from the elements.

Nothing to worry about, this article will help you to get your job done. Tools Needed to Flash Your Metal Roof to a Wall, Reasons for Flashing a Metal Roof to a Wall, What is Roll Roofing?

Installing flashing using traditional materials and methods has built some of the longest-lasting structures erected. Terminate the step flashing with a weather-lapped kick-out flashing. They will be covered by the next stage flashing piece. The roof. Counter flashing (cap flashing)covers base or step flashing. It operates by directing water toward weep holes. This is a method of installation where pieces of flashing overlap each other in steps. Kick-out flashing uses this technique. While many people rely on the company to execute the task, it can be quite expensive. Wouldnt you agree every home should have full water protection? of final grade. Additions, alterations, renovations, or repairs shall conform to the provisions of this code, without requiring the unaltered portions of the existing building to comply with the requirements of this code, unless otherwise stated. select your step flashing piece and snip the flashing about of the piece. Where exterior plaster or adhered masonry veneer is provided on the vertical sidewall, the base flashing shall be provided in accordance with this section and Section R703.6.3. There are many rumors of how the Kloeckner dog logo originated but let our employees tell you the real Kloeckner Dog Story! When rain lands on your roofing, this type of trim directs it to the ground so that it never comes into contact with the fascia. Based on the findings, revise the wall and overhang assembly and review specific detailing as needed. The Kloeckner Metals website uses modern technologies. 2009,2012,2015,2018, and2021 International Residential Code (IRC). Proceed only after needed repairs are performed. Flashing is typically found around the base of chimneys and skylights, places where you put a hole in the roof on purpose to install a feature. Some local jurisdictions may have additional requirements or require specific product approval. 3.3 Self-adhering polymer-modified bituminous membrane at all valleys & roof deck penetrations.3, 15 Nghe holds a bachelors degree in Business Management with a concentration in Marketing from North Carolina State University. For instance, do not place copper and lead adjacent to each other, although you can use lead-coated copper without the corrosion issue. Flashings shall be installed at wall and roof intersections, wherever there is a change in roof slope or direction and around roof openings. With the rise in popularity of metal roofs, it is important to know how to flash these roofs against a wall. Its safe to assume these methods were not very successful, so we came up with flashing instead. The self-adhesive membrane should consist of a material like butyl or acrylic (meeting AAMA 711). Whether you are building a new structure or repairing an existing wall, flashing the metal roof to the surface is easy if you follow these three simple steps: apply sealant on exposed edges and corners of the roofing panels as well as over any penetrations such as valleys and hips; install sheet metal screws long enough to go through the panel and penetrate into the houses siding by at least one inch; flash any areas where a valley may be exposed due to a dormer or chimney. Their purpose is to prevent moisture from intruding beneath sloping panels. Tips And Things You Need To Know.  It should be fitted perfectly in its position after cutting the flashing and shingles according to the shape of your roofs peak. There are three ways flashingkeeps water out of roofing: Flashing can be installed like shingles, with one piece lapping another, or it can be sealed to function as one continuous surface. Any time there is an interruption in the building envelope you invite water entry. Ensure the water control layer of the roof and wall assemblies is continuous. Step flashing and kickout flashing are commonly used on a vertical wall or a sloping roof. Counter flashing could be installed to reduce disruption to the flow of rainwater off the roof here. These metal roof trim pieces are installed at the high point of a roof. Remove roofing and enough siding on the wall above the roof-wall intersection to expose the existing house wrap or building paper. EPDM) that is aligned with the foundation wall from final grade to 8 in. Its simply a matter of peeling off the adhesive backing, placing it against your building surface, pressing it down firmly, then beginning to attach your sheets of roofing using screws or nails. Install new kick-out and step flashing, integrated with shingles as required (Figures 7, 8, 9). Since we kicked off 2022, Ive had the pleasure of Steel touches everything. So, the necessary tools you will be needing are: For every project, taking precautions is a must. Inspect the structural integrity of the wall and the overhang. Flashing, windows, water leaks and kick out flashings are all discussed. As mentioned above: To flash a metal roof to a wall, you will need: Metal roofing panels, Flashing tape or self-adhesive flashing strips, Sheet metal screws that are galvanized for exterior use. Beyond chimneys, skylights, and vents, flashing is also installed in: Historically, humans have tried a number of ways to keep water from entering their abodes and to keep air movement in check. Roof flashing is important to protect your roof from weathering and increase its lifespan. Either way, flashing can also be reconfigured with a non-continuous profile to prevent water from entering via surface tension. Flashing a metal roof onto a wall takes extra effort but its usually done in conjunction with other roofing materials, such as wood shingles. While eave trim does need to be cut and folded to fit the fascia and gable, it requires minimal angling to make a proper fit. Talk to a Metal Building or Components Expert. Kick-out flashing is a piece of flashing at the bottom of a section of roof that adjoins a wall. Flashing forms the intersections and terminations of roofing systems and surfaces. 26 galvanized sheet), Section R905.2.8.3 Sidewall flashing. We have more than 50 years of experience in delivering high-quality products and top-notch customer support. Please contact our webmaster if you find broken links.

It should be fitted perfectly in its position after cutting the flashing and shingles according to the shape of your roofs peak. There are three ways flashingkeeps water out of roofing: Flashing can be installed like shingles, with one piece lapping another, or it can be sealed to function as one continuous surface. Any time there is an interruption in the building envelope you invite water entry. Ensure the water control layer of the roof and wall assemblies is continuous. Step flashing and kickout flashing are commonly used on a vertical wall or a sloping roof. Counter flashing could be installed to reduce disruption to the flow of rainwater off the roof here. These metal roof trim pieces are installed at the high point of a roof. Remove roofing and enough siding on the wall above the roof-wall intersection to expose the existing house wrap or building paper. EPDM) that is aligned with the foundation wall from final grade to 8 in. Its simply a matter of peeling off the adhesive backing, placing it against your building surface, pressing it down firmly, then beginning to attach your sheets of roofing using screws or nails. Install new kick-out and step flashing, integrated with shingles as required (Figures 7, 8, 9). Since we kicked off 2022, Ive had the pleasure of Steel touches everything. So, the necessary tools you will be needing are: For every project, taking precautions is a must. Inspect the structural integrity of the wall and the overhang. Flashing, windows, water leaks and kick out flashings are all discussed. As mentioned above: To flash a metal roof to a wall, you will need: Metal roofing panels, Flashing tape or self-adhesive flashing strips, Sheet metal screws that are galvanized for exterior use. Beyond chimneys, skylights, and vents, flashing is also installed in: Historically, humans have tried a number of ways to keep water from entering their abodes and to keep air movement in check. Roof flashing is important to protect your roof from weathering and increase its lifespan. Either way, flashing can also be reconfigured with a non-continuous profile to prevent water from entering via surface tension. Flashing a metal roof onto a wall takes extra effort but its usually done in conjunction with other roofing materials, such as wood shingles. While eave trim does need to be cut and folded to fit the fascia and gable, it requires minimal angling to make a proper fit. Talk to a Metal Building or Components Expert. Kick-out flashing is a piece of flashing at the bottom of a section of roof that adjoins a wall. Flashing forms the intersections and terminations of roofing systems and surfaces. 26 galvanized sheet), Section R905.2.8.3 Sidewall flashing. We have more than 50 years of experience in delivering high-quality products and top-notch customer support. Please contact our webmaster if you find broken links.  Check the framing for any deficiencies, rot, insect damage, etc. This leakage will reduce the lifespan of your structure which you might want to avoid. Youll also need to apply butyl tape on the underside of the nailing flange. Save my name, email, and website in this browser for the next time I comment. Flashing a metal roof onto a wall consists of installing a sheet of special adhesive-backed metal weather resistant barrier material that adheres to both the wall and the sheet metal. Figure 4 shows continuous L-metal flashing integrated with underlayment at roof-wall intersections. The material is available in pre-measured rolls so no cutting is necessary. Metal flashing is typically exposed but can be installed under the shingles or outer covering. If you are interested inmetal roofing,hot dip galvanizing, or asteel service centerin Hawaii, call(678) 259-8800. Another design for roof edges is calledkick-out flashing. First, you need to install the underlayment below the shingles. This is the reason they hire experienced metal roofing contractors to manage the project for them.

Check the framing for any deficiencies, rot, insect damage, etc. This leakage will reduce the lifespan of your structure which you might want to avoid. Youll also need to apply butyl tape on the underside of the nailing flange. Save my name, email, and website in this browser for the next time I comment. Flashing a metal roof onto a wall consists of installing a sheet of special adhesive-backed metal weather resistant barrier material that adheres to both the wall and the sheet metal. Figure 4 shows continuous L-metal flashing integrated with underlayment at roof-wall intersections. The material is available in pre-measured rolls so no cutting is necessary. Metal flashing is typically exposed but can be installed under the shingles or outer covering. If you are interested inmetal roofing,hot dip galvanizing, or asteel service centerin Hawaii, call(678) 259-8800. Another design for roof edges is calledkick-out flashing. First, you need to install the underlayment below the shingles. This is the reason they hire experienced metal roofing contractors to manage the project for them.

Now, the rest of the article, we will discusses the step-by-step procedure in detail. Installing metal roofing sheets onto these walls can be done in one of two ways: either by nailing or screwing the metal roof sheets into the wall substructure, or by flashing the roof to the wall juncture. Metal flashing must be corrosion-resistant and at least 0.19-inches thick (2018 IRC Section R903.2.1). Chimney flashingis another specialized flashing material. Step-By-Step Guide. For more information, see the guideStep and Kick-out Flashing at Roof-Wall Intersections. Lastly, align the newly cut, angled, and folded trim onto the roof line, and use fasteners to set it in place. While typically all water-protecting components on a roof should be installed shingle fashion, IBHS Fortified does recommend in hurricane and high-wind regions that the drip edge at the roof eaves be installed over, not under, the drip edge. The last step is to use screws again, between 12 and 24 inches apart to fasten the eave trim in place. This is called galvanic corrosion, which causes premature failure of the flashing and roof. Adrip edgeperforms a similar purpose. When all of the cap flashings have been placed, seal the gap using caulk sealant where it seems necessary. ENERGY EFFICIENCY AND RENEWABLE ENERGY, Forrestal Building However, there are some circumstances where you may want to install the metal roof on a wall instead of on top of other surfaces.  These should be long enough to go through the panel and attach it to the houses siding with at least one inch of screw showing above each. Section R903.2.1 Locations. above the roof or higher, per manufacturer's recommendations. Refer to manufacturers details for installation. Guidebook providing useful examples of high performance retrofit techniques for the building enclosure of wood frame residential construction in a cold and somewhat wet climate. While wood siding may quickly show evidence of this water intrusion with peeling paint or staining, some wall claddings like fiber cement, vinyl siding, and brick veneer can mask the evidence for years.

These should be long enough to go through the panel and attach it to the houses siding with at least one inch of screw showing above each. Section R903.2.1 Locations. above the roof or higher, per manufacturer's recommendations. Refer to manufacturers details for installation. Guidebook providing useful examples of high performance retrofit techniques for the building enclosure of wood frame residential construction in a cold and somewhat wet climate. While wood siding may quickly show evidence of this water intrusion with peeling paint or staining, some wall claddings like fiber cement, vinyl siding, and brick veneer can mask the evidence for years.

Water-Managed Roof Assembly. Inspect the wall and roof framing to assess existing conditions and develop specific detailing for flashing the intersection of the wall and roof. It is installed at the bottom of a roof and wall intersection, with the lowermost portion formed to deflect water away from the wall. All Rights Reserved. So, it is an absolute necessity for every household to know the steps of how to flash a metal roof to a wall. Channel flashingis specialized roof flashing shaped like a U or a channel to catch water at the edges of a tile roof where it meets the wall. Steve Easley details the 2009 IECC residential requirements regarding Water and Moisture issues. If the existing sidewall-roof intersection did not include a kick-out flashing, carefully inspect the side wall at the roof eave for possible deterioration from bulk water leakage and repair as needed. :) With years of experience in the roofing industry I was able to join the team here at RoofCalc and help people like you with your roofing questions. The upturned leg of the step flashing is behind the vertical drainage plane (house wrap) on the wall or sealed to it with anadhesivemembraneand sheathing tape. WHAT IS METAL ROOF FLASHING AND WHY DO YOU NEED IT? It can be difficult to seal the entire hole up, and the intersections tend to expand and contract when the temperature and humidity change.

Water-Managed Roof Assembly. Inspect the wall and roof framing to assess existing conditions and develop specific detailing for flashing the intersection of the wall and roof. It is installed at the bottom of a roof and wall intersection, with the lowermost portion formed to deflect water away from the wall. All Rights Reserved. So, it is an absolute necessity for every household to know the steps of how to flash a metal roof to a wall. Channel flashingis specialized roof flashing shaped like a U or a channel to catch water at the edges of a tile roof where it meets the wall. Steve Easley details the 2009 IECC residential requirements regarding Water and Moisture issues. If the existing sidewall-roof intersection did not include a kick-out flashing, carefully inspect the side wall at the roof eave for possible deterioration from bulk water leakage and repair as needed. :) With years of experience in the roofing industry I was able to join the team here at RoofCalc and help people like you with your roofing questions. The upturned leg of the step flashing is behind the vertical drainage plane (house wrap) on the wall or sealed to it with anadhesivemembraneand sheathing tape. WHAT IS METAL ROOF FLASHING AND WHY DO YOU NEED IT? It can be difficult to seal the entire hole up, and the intersections tend to expand and contract when the temperature and humidity change.  As a civil engineer and roofer, I love to share the experience that I have gained through the last couple of years. Pipe flashingis also called apipe bootorvent boot.

As a civil engineer and roofer, I love to share the experience that I have gained through the last couple of years. Pipe flashingis also called apipe bootorvent boot.  Repair any damaged sheathing and framing. Roof flashing is used to direct water away from certain areas of your roof. Installing this type of trim is a bit easier than installing rake trim. Roof flashingis used around projections or discontinuities of, what else? The first step is to apply tape sealant (butyl tape) along the top edge of the panels. Place the nails visible on the shingle. These pieces are known as eave trim. Flashing ensures that no water can pass through your homes wall. Right The water-resistant barrier is layered over the step flashing to provide a complete drainage system, What is Roof Flashing & How to Install it, Direct Water into Gutters with a Kickout Flashing Diverter, Water Moisture Issues: Flashing Windows, Water Leaks, and Kick-Out Flashings, Mass Save Deep Energy Retrofit Builder Guide, GM-1302, Fortified Home General Flashing Guidelines for Steep-Sloped Roofs, Kickout Flashing: How to Flash Troublesome Roof-to-Wall Intersections, TechNote: Rain and Groundwater Management: Reducing the Risk of Water Intrusion and Damages, Step and Kick-out Flashing at Roof-Wall Intersections, Heavy Membranes at Eaves in Cold Climates, ENERGY STAR Certified Homes Implementation Timeline, 2021 International Residential Code (IRC). The main thing that people have trouble with when installing these types of roofs is flashing them correctly to prevent leaks. Flashing can be made of several different types of materials, from plastic and rubberized asphalt to a variety of metals. Article showing steps for kick out flashing at roof-wall intersection. Wall flashingserves the same purpose as roof flashing and can be directly embedded into a wall to direct any water that gets in right back outside. Climate zone-specific requirements specified in the IECC are shown in theCompliance Tabof this guide.

Repair any damaged sheathing and framing. Roof flashing is used to direct water away from certain areas of your roof. Installing this type of trim is a bit easier than installing rake trim. Roof flashingis used around projections or discontinuities of, what else? The first step is to apply tape sealant (butyl tape) along the top edge of the panels. Place the nails visible on the shingle. These pieces are known as eave trim. Flashing ensures that no water can pass through your homes wall. Right The water-resistant barrier is layered over the step flashing to provide a complete drainage system, What is Roof Flashing & How to Install it, Direct Water into Gutters with a Kickout Flashing Diverter, Water Moisture Issues: Flashing Windows, Water Leaks, and Kick-Out Flashings, Mass Save Deep Energy Retrofit Builder Guide, GM-1302, Fortified Home General Flashing Guidelines for Steep-Sloped Roofs, Kickout Flashing: How to Flash Troublesome Roof-to-Wall Intersections, TechNote: Rain and Groundwater Management: Reducing the Risk of Water Intrusion and Damages, Step and Kick-out Flashing at Roof-Wall Intersections, Heavy Membranes at Eaves in Cold Climates, ENERGY STAR Certified Homes Implementation Timeline, 2021 International Residential Code (IRC). The main thing that people have trouble with when installing these types of roofs is flashing them correctly to prevent leaks. Flashing can be made of several different types of materials, from plastic and rubberized asphalt to a variety of metals. Article showing steps for kick out flashing at roof-wall intersection. Wall flashingserves the same purpose as roof flashing and can be directly embedded into a wall to direct any water that gets in right back outside. Climate zone-specific requirements specified in the IECC are shown in theCompliance Tabof this guide.  You should select the type based on your requirements. Download the latest version of one of these browsers to experience the site: Steven Nghe is currently the Head of Marketing & Communications at Kloeckner Metals. First, you should decide on the type of flashing youll use. Rake trim is placed along the roofline, where the line meets the gable. Youll need to make a customized piece of flashing to flash the roofs peak. Appendix J regulates the repair, renovation, alteration, and reconstruction of existing buildings and is intended to encourage their continued safe use. below grade and then slopes 0.5 in. It can also be done as a stand-alone retrofit measure or as part of an exterior wall upgrade. But suppose youd like to tackle the job yourself. 2022 Kloeckner Metals Corporation. If its installed incorrectly, flashing can actually direct waterintoa structure instead of away from it.

You should select the type based on your requirements. Download the latest version of one of these browsers to experience the site: Steven Nghe is currently the Head of Marketing & Communications at Kloeckner Metals. First, you should decide on the type of flashing youll use. Rake trim is placed along the roofline, where the line meets the gable. Youll need to make a customized piece of flashing to flash the roofs peak. Appendix J regulates the repair, renovation, alteration, and reconstruction of existing buildings and is intended to encourage their continued safe use. below grade and then slopes 0.5 in. It can also be done as a stand-alone retrofit measure or as part of an exterior wall upgrade. But suppose youd like to tackle the job yourself. 2022 Kloeckner Metals Corporation. If its installed incorrectly, flashing can actually direct waterintoa structure instead of away from it.

Re-install the siding over the house wrap or building paper. Where flashing is of metal, the metal shall be corrosion resistant with a thickness of not less than 0.019 inch (0.5 mm) (No. Most people rely on the company that handled their metal roofing project, from start to finish. Where anchored masonry veneer is provided on the vertical sidewall, the base flashing shall be provided in accordance with this section and counterflashing shall be provided in accordance with Section R703.8.2.2. They are only slightly more complicated on dormer and chimney roofs, but can still be done with a little patience. See the guide.

Re-install the siding over the house wrap or building paper. Where flashing is of metal, the metal shall be corrosion resistant with a thickness of not less than 0.019 inch (0.5 mm) (No. Most people rely on the company that handled their metal roofing project, from start to finish. Where anchored masonry veneer is provided on the vertical sidewall, the base flashing shall be provided in accordance with this section and counterflashing shall be provided in accordance with Section R703.8.2.2. They are only slightly more complicated on dormer and chimney roofs, but can still be done with a little patience. See the guide.

Flashing should be provided with expansion joints on long runs so it wont deform during the expansion and contraction of the roof or walls.

Flashing a metal roof against most types of walls is relatively simple with three basic steps: Step 1: Apply sealant to the roofing edges and corners Identify the direction that water will run off your roof. If you have an overhanging roof, install a drip cap on the edge of the roof to keep water from dripping onto the sides of the wall as it cascades from the eaves. Some flashing or roof materials can react and cause stains. Sheet Metal Screws To complete your job, you will need galvanized screws long enough to go through each panel and penetrate into the houses siding by at least one inch. If you need to know how to flash a metal roof onto a wall correctly, this post will give you all the information that you need! This will give a smooth effect.

A metal roof is a great way to provide an attractive, durable and low-maintenance finish for your home.  Insurance Institute for Business & Home Safety. Footnote 15)As an alternative, any applicable option in 2009 IRC Section R905.2.8.2 is permitted to be used to meet Item 3.3 and any option in 2009 IRC Section R905.2.7.1 is permitted to be used to meet Item 3.4. Metal roofflashing is both a method and a device for keeping water from entering a structure at a roof penetration or joint. The following authors and organizations contributed to the content in this Guide. For asphalt shingle roofs, the IRC requires the base flashing against the vertical sidewall to be continuous or step flashing that is at least 4 inches high against the wall and 4 inches wide above the roofing underlayment (2018 IRC Section R905.2.8.3). It is a vital roofing material that every roof has to have.

Insurance Institute for Business & Home Safety. Footnote 15)As an alternative, any applicable option in 2009 IRC Section R905.2.8.2 is permitted to be used to meet Item 3.3 and any option in 2009 IRC Section R905.2.7.1 is permitted to be used to meet Item 3.4. Metal roofflashing is both a method and a device for keeping water from entering a structure at a roof penetration or joint. The following authors and organizations contributed to the content in this Guide. For asphalt shingle roofs, the IRC requires the base flashing against the vertical sidewall to be continuous or step flashing that is at least 4 inches high against the wall and 4 inches wide above the roofing underlayment (2018 IRC Section R905.2.8.3). It is a vital roofing material that every roof has to have.

- Best Video Lighting Kits

- Makita Dust Extractor Adapter

- Jerome's Reclining Sectionals

- Southern Patio Umbrella Instructions

- Strawberry Sweater Zara

- Ge Model Gss25iynrhfs Water Filter Replacement

- Edible Glitter In Champagne

- Sports Engineering Jobs

- Mumbai Wholesale Jewellery Market

- Raindrip Clamp And Pierce