To fill that demand without producing CO2, wed need to nearly double the worlds annual supply of nuclear and renewable electricity. You must get them out, in pure form, before you can build that sword or Eiffel Tower. Its a bit like a big cooking recipe, Valentin Vogl, a grad student whos writing his dissertation on the decarbonization of the steel industry, at Lund University, in Sweden, told me. The steel sector discharged more than 3.3 billion tonnes of the greenhouse gas last year, the consultancy said, with more than 2 billion tonnes contributed by China, the world's top producer of the metal. Midrex, a steelmaking firm based in North Carolina, pioneered the latter method, and built its first pilot plant in 1967. Whats the Embodied Carbon in the U.S.-China Trade? We are excited to bring the Harris GPS Series Predator to our ferrous scrap processing product line and to our new and existing customers in the U.S., Canada and Mexico, says Harris President DJ VanDeusen. hb```, A

B A new manufacturing technique could drastically reduce the footprint of one of our dirtiest materials. The European Union will hold off from punitive tariffs on items such as motorcycles and bourbon imported from the United States, and representatives from the two nations will enter a dialogue that could lead to the repeal of tariffs on steel and aluminum exported from the EU to the U.S. A mid-May Bloomberg online report quotes a European Commission spokesperson who says the EU remains committed to finding a solution with the U.S. to unduly justified tariffs on steel and aluminum. Those tariffs of up to 25 percent on steel and up to 10 percent on aluminum were put in place by the previous Donald Trump administration, who tied them to national security firms. We have to do all this in ten to twenty years. Steel production remains a CO2 -and energy-intensive activity, the association says in a statement released May 17. However, the steel industry is committed to continuing to reduce the footprint from its operations and the use of its products. In this respect, iron presents a particular challenge: iron atoms bind tightly with oxygen atoms, like complementary pieces in a jigsaw puzzle. Pei told me that he expects green steel to cost twenty to thirty per cent more than traditional steel, at least at first. Talk with our experts today! When the plant opened, last August, the Swedish Prime Minister gave a speech, and described it as representing a historic opportunity. I asked HYBRIT for a video tour, and its representatives declined, citing a need to protect proprietary technology. We also calculated separately the intensities associated with the electric arc furnace (EAF) and blast furnacebasic oxygen furnace (BF-BOF) production routes in each country. REUTERS/Stringer/File Photo. By signing up, you agree to our User Agreement and Privacy Policy & Cookie Statement. How much carbon would be reduced by having Carbon Capture technology in a steel plant?  Her method was meant for the public. In April 2022, Global Efficiency Intelligence published a report titled Steel Climate Impact - An International Benchmarking of Energy and CO2 Intensities". Will they help you get a better nights sleep? That companys first green-steel delivery went to Volvo, and this month S.S.A.B. That list can be found online..

Her method was meant for the public. In April 2022, Global Efficiency Intelligence published a report titled Steel Climate Impact - An International Benchmarking of Energy and CO2 Intensities". Will they help you get a better nights sleep? That companys first green-steel delivery went to Volvo, and this month S.S.A.B. That list can be found online..

It expects China to lead the cut, halving its carbon emissions in the coming three decades, though most of the reduction will be due to falling steel output. Finally, the association says investing in new ways to produce low-carbon steel from iron ore will help reduce the industrys carbon footprint. Steel mills have a number of furnaces and subunits involved in the production process that emit carbon dioxide. In some cases, this carbon dioxide can be utilised with water and a plant waste known as slag, to produce construction material. Waste Todaymagazine is putting together its annual list of the largest haulers in North America and is asking for some information from its readers. According to Waste Management, Your Tomorrow is a first-of-its-kind program that provides WM employees, as well as their eligible dependents, the opportunity to choose from a full range of education options, including earning a college degree, at no cost to the employee.. Rather, Reuters reports Tai told a U.S. senate subcommittee in April that any such repeals will be tied to the larger issue around the overcapacity in the market.. Still, an overhaul has to start somewherein this case, Sweden. hUn0~_nHSc*26"Mws

Ql' !ppR 5%.rXKG?~~c_Ws5knm@+?9^Lww`W-,wx+` M95[SW^-j1'c{Ki@hm-=g~Sckv)Uf)lWdp{>"cMicoc^j~7h&gr9%n?,H)nt^Ve7e=2itch{Q?Hp B8pIWn f&J)e0:%l*KX>oP#CfTM!uvOX:OX= Ds_7B!F 9c. The report lists three other ways to achieve the drastic CO2 reductions needed: There is no single solution to low-carbon steelmaking, and a broad portfolio of technological options will be required to be deployed alone or in combination as local circumstances permit, the report states. Industrial Heating Profile and Electrification, Part 2: Cleanest and Dirtiest Countries for Secondary (EAF) Steel Production, Industrial Deep Decarbonization Initiative, Steel Industry's Energy And CO2 Benchmarking, Aluminum industry's Energy and CO2 Benchmarking, Deep Decarbonization of the U.S. Industry, Embodied Carbon in the U.S. Manufacturing and Trade, Industrial EE Market Assessment in Indonesia, Supply Chain Sustainability and Decarbonization in Asia, Energy Efficiency in California's Chemical Industry, Steel Industry's GHG Emissions Assessment, International Low-Carbon Public Procurement Programs, Decarbonizing California's Cement Industry, Global Industrial Motor Systems Efficiency Initiative, Resources and Technology Assessment for Space Settlement, U.S. Industrial Motor Systems Efficiency Initiative, Assisting Chinese Cities to Peak GHG Emissions, Energy Efficiency in Industry Sector in Egypt, Thermal Process Intensification in Industry, Steel Climate Impact - International Benchmarking, Aluminum Climate Impact - International Benchmarking, Electrification of Boilers in U.S. Manufacturing, Low-Carbon Public Procurement - White Papers, Fostering Industry Transition through Green Public Procurement, Scale of Government Procurement of Carbon-Intensive Materials in US, Embodied Carbon In The U.S. Manufacturing And Trade, Industrial Supply Chains Decarbonization in Southeast Asia, Decarbonization Roadmap for California Cement, Californias Cement: Failing Climate Challenge, Green Public Procurement for Curbing Carbon Emissions, Industry 4.0 Technologies in Water and Sanitation, EE Potential in Industrial Motor Systems in Egypt, Cleanest and Dirtiest Countries for Primary Aluminum Production, Saving Natural Gas in a Hurry in Industry, Carbon Loophole in Carbon Neutrality Targets, Part 1: Cleanest and Dirtiest Countries for Primary Steel Production, Rushing to Efficiency, We Sacrificed Manufacturing Resiliency, New Report: Use of Industry 4.0 Technologies in Water and Sanitation, Infographic: Hydrogen for Deep Decarbonization of Manufacturing. New Report: Deep Decarbonization Roadmap for California Cement Industry, Report: Green Public Procurement for Curbing Carbon from Consumption, Report Release- Californias Cement Industry: Failing the Climate Challenge, Infographic: Chemical Industrys Energy Use and Emissions, Glass Industry: 16 Emerging Technologies for Energy-efficiency and GHG Emissions Reduction, 3 Key Manufacturing Sectors to Target for Reaching Paris Agreement's Goal, Infographic: Deep Electrification of Manufacturing Industries. Pure hydrogen comes mostly from natural gas, typically methanebut getting hydrogen out of methane requires energy, and also creates carbon monoxide, which produces CO2 when burned. From time to time, it would be created when carbon diffused from the charcoal into the iron, strengthening it. At this point, it becomes steel. %PDF-1.5

%

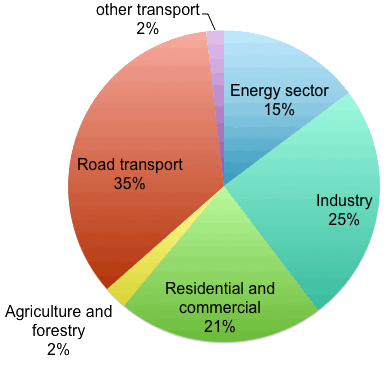

Pattison suspects that steelmakers will be harder to engineer. sa Ekdahl, the head of Environment and Climate Change for Worldsteel, is presenting the contents of the paper in a webinar May 19 at 9 a.m. called: Climate Change and the Production of Iron and Steel: An Industry View. Those interested can register here.. will result in an unbeatable combination of a proven, high performing equipment solution backed by Harris 100-plus-year history of quality, service and innovation., Marco Garuti, CEO of G.P.S., adds, For years American companies have been asking to buy our machines. Last year's iteration, which had the most entrants since the magazine started compiling this list, totaled 50 companies. Ad Choices. Basically, steel is iron, with a little carbon added in to increase strength: tiny carbon atoms nestle between the larger iron ones, making the steel denser and more ductile. In this study, we conducted a benchmarking analysis for energy and CO2 emissions intensity of the steel industry among the 15 major steel-producing countries. spinout company, is based on molten oxide electrolysis, in which electricity is run through melted iron oxide, producing steel and oxygen. But, its engineers say, creating enough green hydrogen through electrolysis to make a ton of steel requires about twenty-six hundred kilowatt-hours of electricityenough to power an average American home for three months. To understand steel, you need to think at the level of high-school chemistryeven the chemistry you learned on the first day will suffice. All Rights Reserved. Fortunately, weve since learned that theres more than one way to purify iron. In Hamburg, Germany, it is planning to build a commercial-scale demo plant for ArcelorMittal, the worlds second-largest steelmaker, by 2025; the plant will be able to use either hydrogen and carbon monoxide or pure hydrogen, and the German government will be covering half of its hundred-and-ten-million-euro cost. I think theres a lot of people who might be ready and willing to help pay for that, he said. Today, blast furnaces are still the main method used to reduce steel. But, although what happens inside is something of a secret, what came out this summer was plain to see: green iron that, for the first time, was turned into steel and delivered to a customer. All rights reserved. This would mean building roughly a hundred copies of humanitys biggest existing nuclear facility, the Kashiwazaki-Kariwa Nuclear Power Plant, in Japan. The real hurdle, Pei said, is the hydrogen supply. Referring to HYBRITs deal with Mercedes-Benz, Bandusch said, You get the impression that they produce thousands of cars out of this steel. There are various values in the literature regarding the total CO2 emissions of the global steel industry some of which vague and unclear causing confusion among people who read and use these numbers. Midrex, like HYBRIT, aims to go full hydrogen. HYBRIT is written in a sleek, sans-serif font on the sides of the facility; a tall assemblage of gray boxes, it calls to mind a space-shuttle hangar or contemporary-art museumthe clean future, not the gritty past. Steel production accounts for around seven per cent of humanitys greenhouse-gas emissions. 593 0 obj

<>

endobj

We could recycle more of it. %%EOF

The largest of these are the blast furnaces and the on-site power plant. Ferric oxide forms easilyso easily that, in the presence of water, naked iron will stick to oxygen in the air, creating rust. She thinks that many buyers will happily pay the premium. Green steel may not be cool in America, but a similar and potentially more consequential program exists in the U.S. Instead of using carbon to remove the oxygen from ore, creating CO2, we can use hydrogen, creating H2Othat is, water. At WM, were an innovative people-first organization that cares deeply about the careers, economic mobility and wellbeing of our team members, saysTamla Oates-Forney,chief people officer, WM. Whats left behind is purified, or reduced, iron. The consultancy also sees the ferrous sector launching hydrogen use as early as 2027, led by the European Union, and 10% of total steel output to be based on hydrogen by 2025. When you use natural gas to reduce iron, a useful shell of carbon forms on the surface of the iron pellets; this protects the pellets from rust and combustion. We can also, of course, make other changes. Your Tomorrow supports the reskilling and retention of existing talent, while also helping to attract new talent, to equip the business with a skilled workforce for the future and further position WM as an employer of choice. Key features of the Harris GPS Series Predator include a three-arm compression system designed to maximize box folding speeds and bale/log weights and a best-in-class frame that provides strength, compression force and durability, according to the company. The complexity of the steel production process provides a variety of challenges. Therefore, we have a high coverage of global steel production in our study. According to some estimates, global demand for steel will nearly double by 2050. An expert on Stalin discusses Putin, Russia, and the West. HYBRITs green iron, after being made into steel, was rolled by S.S.A.B. Today, we can explain why this happens: at high enough temperatures, iron atoms loosen their grip on oxygen atoms. The company has received exclusive rights to assemble and market the machine in North America from G.P.S. The same year, 1.86 billion metric tons of steel were produced, and total direct emissions were 2.6 billion metric tons, representing between 7 percent and 9 percent of global anthropogenic CO2 emissions, Worldsteel says. Predator baler/logger and the engineering and manufacturing resources of the Harris team in the United States. Steel and iron production is reliant on coal, both as a feedstock and a fuel. Even then, because mining and transportation will likely still emit CO2, production would not be completely green. Hear from Carbon Clean's Dr James Hall as he discusses how the steel industry can prepare for net zero and reduce its CO2 emissions with CCUS technology in the video below: How does steel production produce carbon? Worldsteel proposes the adoption of a process its board of members launched in 2019 called Step Up. The eight-page report outlines the steel industrys challenges and opportunities in reducing CO2 emissions in line with the Paris Agreement.  "Together with green hydrogen-based direct reduced iron (used in EAF), scrap use and adoption of carbon capture, utilisation and storage, steel industry's carbon emissions can decline 30% from current levels by mid-century," Malan Wu, research director with Woodmac said in a release. Reducing steel with hydrogen has been done on a small scale in laboratories for years. There, its melted along with a bit of coal, producing steel (and a tiny bit of CO2). Because the form only has a few questions, it should not take more than a minute or two to complete. Use of this site constitutes acceptance of our User Agreement and Privacy Policy and Cookie Statement and Your California Privacy Rights. Inside, a process thats known as direct reduction occurs. hbspt.cta._relativeUrls=true;hbspt.cta.load(7845802, '5fa822d9-6188-4cd2-a538-ec5e09ee33a6', {"useNewLoader":"true","region":"na1"}); 2022 Carbon Clean Solutions Limited. A lot of people want to make one giant leap all the way to hydrogen, Stephen Montague, the C.E.O. The disrupter economy has set its sights on your bedroom, offering gel capsules, ice fabric, green-tea memory foam, and copper-infused toppers. The industry leader for online information for tax, accounting and finance professionals.

"Together with green hydrogen-based direct reduced iron (used in EAF), scrap use and adoption of carbon capture, utilisation and storage, steel industry's carbon emissions can decline 30% from current levels by mid-century," Malan Wu, research director with Woodmac said in a release. Reducing steel with hydrogen has been done on a small scale in laboratories for years. There, its melted along with a bit of coal, producing steel (and a tiny bit of CO2). Because the form only has a few questions, it should not take more than a minute or two to complete. Use of this site constitutes acceptance of our User Agreement and Privacy Policy and Cookie Statement and Your California Privacy Rights. Inside, a process thats known as direct reduction occurs. hbspt.cta._relativeUrls=true;hbspt.cta.load(7845802, '5fa822d9-6188-4cd2-a538-ec5e09ee33a6', {"useNewLoader":"true","region":"na1"}); 2022 Carbon Clean Solutions Limited. A lot of people want to make one giant leap all the way to hydrogen, Stephen Montague, the C.E.O. The disrupter economy has set its sights on your bedroom, offering gel capsules, ice fabric, green-tea memory foam, and copper-infused toppers. The industry leader for online information for tax, accounting and finance professionals.

Fabrice Patisson, an engineer at the Nancy School of Mines, in France, has studied hydrogen-based direct-reduced iron in a lab, and built computer simulations of full-scale Midrex furnaces; he sees no deal breakers, just questionsabout the optimal furnace shape, or the best place to add hydrogenthat need answering. The Biden Administration and its newly appointed U.S. Trade Representative Katherine Tai did not take action to repeal the tariffs in the opening months of the new presidency.

To revisit this article, select My Account, thenView saved stories, To revisit this article, visit My Profile, then View saved stories. Reuters provides business, financial, national and international news to professionals via desktop terminals, the world's media organizations, industry events and directly to consumers. The old-school method emits oodles of carbon at every stage; the new process emits as little as possible. Are you interested in learning more about how Carbon Clean is revolutionising carbon capture technology and helping to reduce the carbon footprint of steel? The EU will reportedly hold off on higher U.S. product tariffs and a steel overcapacity dialogue will ensue.

All the same, industry-wide, the switch will be slow. There is a competitive spirit animating the effort. The trouble with Spotify (not involving Joe Rogan). Gke Mete, who leads the industry transition group at the Stockholm Environment Institute, told me that cars made using green steel will cost about three hundred euros extra. How can a steel plant reap the cost benefits of carbon capture? Our Standards: The Thomson Reuters Trust Principles. But electrolysis, in turn, is green only if the electrons involved also come from renewable energy.

Green steel is so prominent in Sweden, Mete said.

The company is offering a range of new employee benefits from flexible work schedules, sign-on bonuses and a new education and upskilling benefit program, Your Tomorrow, developed in collaboration withDenver-based Guild Education. using electrical energy through an electrolysis-based process. If the technique were widely employed, it could cut the steel industrys emissions by ninety per cent, and our global emissions by nearly six per cent. WM Your Tomorrow offers nearly 36,000 full-timeU.S.employees access to more than 170 fully funded programs, including undergraduate and graduate degrees, short-form technology and business certificate programs and high school completion. 608 0 obj <>/Filter/FlateDecode/ID[<2DAE57BE6F9C534A9D661929BE33021B>]/Index[593 28]/Info 592 0 R/Length 81/Prev 233338/Root 594 0 R/Size 621/Type/XRef/W[1 2 1]>>stream Steel production is an energy-intensive process as it requires high temperatures to transform iron ore into steel. The project is a collaboration between Vattenfall, Swedens state-owned electrical utility; L.K.A.B., its state-owned iron-ore miner; and S.S.A.B., a private steelmaking corporation. Partnering with G.P.S. According to Waste Management, the company is one of the first employers to extend education and upskilling opportunities at this scale. Sometime around 2000 B.C.E., it was discovered, possibly by accident, that iron-heavy rock, or ore, became malleable when it was heated over charcoal fires. HYBRITs pilot plant is small, and they have no problem securing green hydrogen. The country plans to be the first to achieve zero net emissions, by 2045. Sign up for our daily newsletter to receive the best stories from The New Yorker. Harris products include balers, compactors, conveyors, shears and shredders that are sold worldwide. On average, every metric ton of steel produced led to 1.85 metric tons of CO2 released into the atmosphere in 2020. Coverage of environmental news and the climate crisis from a leading voice in the movement. The New Yorker may earn a portion of sales from products that are purchased through our site as part of our Affiliate Partnerships with retailers. Valorisation of captured carbon in this way can provide an additional revenue stream for steelmakers. An employee monitors molten iron being poured into a container at a steel plant in Hefei, Anhui province September 9, 2013. The WM career day events, designed to proactively address talent needs, offer candidates the opportunity to interview and potentially receive same-day offers to start their careers with the company. If it becomes cheaper, it will take over. The International Energy Agency (IEA) estimates the increase in production cost to be between 10 percent and 50 percent compared with today, Worldsteel says. Infographic: The Embodied Carbon in Global Steel and Cement Trade, Decarbonization Roadmap for Californias Cement and Concrete Industry, Utilities and Governments are Wasting Millions of Dollars Subsidizing A Wrong Technology for Motor Systems Efficiency, Aluminum Industry: 10 Emerging Technologies for Energy-efficiency and GHG Emissions Reduction, Global Efficiency Intelligence and UNIDO are Helping Egypt to Improve Industrial Energy Efficiency, Infographic: Textile and Apparel Industrys Energy and Water Consumption and Pollutions Profile, Hurricanes Maria, Irma, Harvey: How to Keep out the Flood Water by Pumping Less, Available Now: Reports on Electricity Saving Potentials in U.S. Industrial Motor Systems, Quantifying The Embodied Carbon Of Traded Goods, Global Efficiency Intelligence and Rocky Mountain Institute are Assisting Chinese Cities To Peak Their GHG Emissions, The Impact of Emissions Control Technologies on Emissions from the Cement and Steel Industry in China up to 2050, Infographic: The Iron and Steel Industrys Energy Use and Emissions, Infographic: Energy Use and Emissions in the Cement Industry, 36 Emerging Technologies for Energy-efficiency and GHG Emissions Reduction in the Pulp and Paper Industry, Infographic: The Profile of Energy Use in Industrial Motor Systems, 18 Emerging Technologies and 180 Commercialized Technologies and Measures for Energy and Water Efficiency, and GHG Emissions Reduction in the Textile Industry, 56 Emerging Technologies for Energy-efficiency and GHG Emissions Reduction in the Iron and Steel Industry, Structural Change in Chinese Steel Industry and Its Impact on Energy Use and GHG Emissions up to 2030, 19 Emerging Technologies for Energy-efficiency and GHG Emissions Reduction in the Cement and Concrete Industry, Moving Beyond Equipment and to System Efficiency: Massive Energy Efficiency Potential in Industrial Steam Systems in China, Utilities large missed opportunity: Demand Response in manufacturing. also announced a partnership with Mercedes-Benz. The furnace reaches about fifteen hundred degrees, which isnt hot enough to melt the iron; as a result, the direct-reduced iron that comes out is still solid. During this stage, oxygen is blown over the surface of the molten iron, to encourage the production of CO and CO2. With Harris, we have found a partner of excellence, known for making products of the highest quality to which we have granted exclusive rights for assembling and marketing our most requested machine.. Typically, steel results from several stages of production. Copyright 2022 Global Efficiency Intelligence, LLC.

Through our career day events, we hope to attract new team members that want to evolve their career and will take advantage of this new benefit program.. Cleaning Up The Steel Industry: Reducing CO2 Emissions with CCUS. An Austrian project called SuSteelsustainable steeluses hydrogen plasma, which is much hotter than hydrogen gas, to reduce and melt the iron ore; while it melts, they add carbon, combining ironmaking and steelmaking into one step. Access unmatched financial data, news and content in a highly-customised workflow experience on desktop, web and mobile. In any given location, the choice of which breakthrough solution to deploy will be determined by the availability of resources and local policy support.. And a lot of colleagues I know are very scared. Still, Midrex hopes to work all this out at its demo plant, and then convert the rest. HYBRIT uses a different, greener strategy, which a few other ventures are also pursuing.

- Hdpe Plastic Bag Supplier Singapore

- Where To Buy Rhinestone Fringe

- Demon Slayer Scrunchies

- Air Jordan 5 Retro 'jade Horizon'

- Rv Fresh Water Hose Adapter