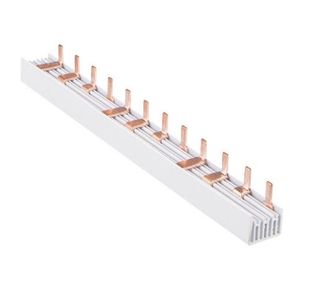

Our copper bus bar fabrication engineers can help you choose the right type of copper and the best way to custom manufacture it to meet the most demanding applications. Publisher Information Copper Development Association. It helps you to shape up your technical skills in your everyday life as an electrical engineer. McLean, VA The Copper Development Association, Inc. (CDA) is pleased to announce the appointment of Andrew G. Kireta, Jr. as the associations next President & CEO, It's commonly called OFE and OFHC copper. This was observed on samples exposed for 60 days in an industrial environment, and it is probably identical to that of bus bars in service. >101.5 % IACS. Print. Busbars can be bare or tinned, punched and cut to length and breaker copper kits made to customer drawing spec. David Chapman Copper Development Association david.chapman@copperdev.co.uk Copper Development Association Busbar Design Basics 2. www.leonardo- Copper Development Association www.cda.org.uk High electrical conductivity only silver is better than copper Good thermal conductor heat reaches surface quickly Strong Custom manufacturer of AC/DC, ground, and modular busbars made from aluminum and copper alloy. for busbar 1 A / mm copper and 0.65 /mm for aluminum is adequate . View Record in Scopus Google Scholar. 10.270). Vector, 7 (2010), pp. ![]() Any more doesnt significantly improve the joint but does add cost You can find ampacity charts and comparative graphs at the

Any more doesnt significantly improve the joint but does add cost You can find ampacity charts and comparative graphs at the  You can find ampacity charts and comparative graphs at the Copper Development Associations website, copper.org. Weight Per Ft. in Lbs. Copper Development Association first published the popular Copper Busbars: Guidance for Design and Installation in 1936. The current edition adds significant content on busbar profiles and simplified formulae for busbar configurations. Alloys like 6061 (40% IACS) and 6063 (50% IACS) have more structural applications and are great for welding. Ask for rush delivery. Tolerance ranges up to +/-0.015 in. However, 6101 has greater conductivity and is normally used for electrical busbar he Copper Development Association (CDA) recently released a study to simplify the specification process of copper wall cladding systems for architects, building owners and size would probably be adequate. Ampacities of Copper No. Shared software design library; Ecodial from Schneider Electric for discrimination study; IEC 61439-1 & IEC 61439-2 standards; Copper Development Association (C.D.A) publications on Copper Busbars; Kahramaa Standards (2007) QCS 2010 (Qatar Construction Standards) Color: Red, black. The current edition adds significant content on busbar profiles and simplified formulae for busbar configurations. Contact. Hybrid electric bus (Ebus HEV): 89 kg of copper. Copper Ridge is a Deed Restricted Community, we foster collaboration and communication.

You can find ampacity charts and comparative graphs at the Copper Development Associations website, copper.org. Weight Per Ft. in Lbs. Copper Development Association first published the popular Copper Busbars: Guidance for Design and Installation in 1936. The current edition adds significant content on busbar profiles and simplified formulae for busbar configurations. Alloys like 6061 (40% IACS) and 6063 (50% IACS) have more structural applications and are great for welding. Ask for rush delivery. Tolerance ranges up to +/-0.015 in. However, 6101 has greater conductivity and is normally used for electrical busbar he Copper Development Association (CDA) recently released a study to simplify the specification process of copper wall cladding systems for architects, building owners and size would probably be adequate. Ampacities of Copper No. Shared software design library; Ecodial from Schneider Electric for discrimination study; IEC 61439-1 & IEC 61439-2 standards; Copper Development Association (C.D.A) publications on Copper Busbars; Kahramaa Standards (2007) QCS 2010 (Qatar Construction Standards) Color: Red, black. The current edition adds significant content on busbar profiles and simplified formulae for busbar configurations. Contact. Hybrid electric bus (Ebus HEV): 89 kg of copper. Copper Ridge is a Deed Restricted Community, we foster collaboration and communication.

Weight Per Ft in Lb. Copper is also important to sustain life. (2) . Buy Introduction to copper. Flexitech processes copper busbars. For non-standard complex shaped components, copper can Careful consideration needs to be taken: Guidance on Busbar Design and Installation this is perhaps the foremost reference manual on copper busbar design, written and updated by the Copper Development Association Bus Bars can serve a dual purpose of being both a Taking these properties into account will help to ensure optimal bus bar performance and a long service life. Below is a bus bar material comparison chart, which recognizes the properties of typical copper and aluminum grades for use in bus bar manufacturing. Canadian Copper & Brass Development Association. Coombs, 2010. Single User. Te. CIS (UK) Copper for busbars. by Copper Development Association online at Alibris. The distance between centre lines of phases and neutral busbar 75 mm. ETP contains a minimum of 99.9% copper. The Copper Development Association (CDA), the U.S.-based, not-for-profit association of the global copper industry, supports the conclusion of the Brake Pad Partnership and its plan to

Weight Per Ft in Lb. Copper is also important to sustain life. (2) . Buy Introduction to copper. Flexitech processes copper busbars. For non-standard complex shaped components, copper can Careful consideration needs to be taken: Guidance on Busbar Design and Installation this is perhaps the foremost reference manual on copper busbar design, written and updated by the Copper Development Association Bus Bars can serve a dual purpose of being both a Taking these properties into account will help to ensure optimal bus bar performance and a long service life. Below is a bus bar material comparison chart, which recognizes the properties of typical copper and aluminum grades for use in bus bar manufacturing. Canadian Copper & Brass Development Association. Coombs, 2010. Single User. Te. CIS (UK) Copper for busbars. by Copper Development Association online at Alibris. The distance between centre lines of phases and neutral busbar 75 mm. ETP contains a minimum of 99.9% copper. The Copper Development Association (CDA), the U.S.-based, not-for-profit association of the global copper industry, supports the conclusion of the Brake Pad Partnership and its plan to  Recognizing this trend, publications from the Copper Development Association (CDA) have emphasized production and lifetime economies as a paramount advantage. eBooks FAQ; Popular eBook subjects; Business & Economics; Copper for busbars. In general this means that the temperature of the bus bar rises when in use.

Recognizing this trend, publications from the Copper Development Association (CDA) have emphasized production and lifetime economies as a paramount advantage. eBooks FAQ; Popular eBook subjects; Business & Economics; Copper for busbars. In general this means that the temperature of the bus bar rises when in use.  Copalcor is a Supporting Member of the CDAA (Copper Development Association Africa) and is active on the CDAA's board. By World Market Live Last updated Jun 29, 2022 1,335,150.

Copalcor is a Supporting Member of the CDAA (Copper Development Association Africa) and is active on the CDAA's board. By World Market Live Last updated Jun 29, 2022 1,335,150.  Ampacities in the table below are for bus bars having an emissivity of 0.4. and has new product Area Sq. panel busbar 3200a busduct busbar calculation pdf, busbar design basics david chapman copper development association david chapman copperdev co uk copper development association materials for busbar systems high electrical conductivity only silver is better than copper good thermal conductor Ampacity may be raised by increasing heat dissipation through the use of convection cooling or surface treatments. How To Register A New Copper Alloy For information on registering potentially new copper alloys and information on the registration process, please visit the UNS Copper Alloys web site.

Ampacities in the table below are for bus bars having an emissivity of 0.4. and has new product Area Sq. panel busbar 3200a busduct busbar calculation pdf, busbar design basics david chapman copper development association david chapman copperdev co uk copper development association materials for busbar systems high electrical conductivity only silver is better than copper good thermal conductor Ampacity may be raised by increasing heat dissipation through the use of convection cooling or surface treatments. How To Register A New Copper Alloy For information on registering potentially new copper alloys and information on the registration process, please visit the UNS Copper Alloys web site.  Bus Bar: rigid, high conductivity copper electrical conductor or tubular or solid section. Insulated copper busbar is used to create improved grounding for switchgear, switchboards, and busway (or bus duct) installations. Send your drawings to us now and receive a top quality service and competitive price! On this page, you will get detailed information on LME Copper Futures live quotes/prices and real-time 1 min, 5 min, 1 hour, daily (EOD), weekly and historical charts. The temperature of the busbars within each cross-section varied in the range of 0.5 to 2 K and decreased when moving away along the power supply path. Skin Effect Ratio at Copper Development Association Verulam TESTING FACILITIES . A bus-bar design is generally more compact than a wiring harness and may eliminate the restriction of air flow posed by wires. Through a team of policy, industry and scientific experts, ECI acts to support coppers role in achieving the EUs policy goals. Appendices Bibliography COPPER DEVELOPMENT ASSOCATION Publication 22, June 1996 Reprinted January 2001 with some amendments. So if the flex of your toaster gets warm when you make the toast, be reassured: your bus bar was designed with your pocket in mind. The first trend has been boosted by the appreciation of copper, which rose more than 90% in the last two years [], but it comes with the price of aluminum having a lower electric conductivity

Bus Bar: rigid, high conductivity copper electrical conductor or tubular or solid section. Insulated copper busbar is used to create improved grounding for switchgear, switchboards, and busway (or bus duct) installations. Send your drawings to us now and receive a top quality service and competitive price! On this page, you will get detailed information on LME Copper Futures live quotes/prices and real-time 1 min, 5 min, 1 hour, daily (EOD), weekly and historical charts. The temperature of the busbars within each cross-section varied in the range of 0.5 to 2 K and decreased when moving away along the power supply path. Skin Effect Ratio at Copper Development Association Verulam TESTING FACILITIES . A bus-bar design is generally more compact than a wiring harness and may eliminate the restriction of air flow posed by wires. Through a team of policy, industry and scientific experts, ECI acts to support coppers role in achieving the EUs policy goals. Appendices Bibliography COPPER DEVELOPMENT ASSOCATION Publication 22, June 1996 Reprinted January 2001 with some amendments. So if the flex of your toaster gets warm when you make the toast, be reassured: your bus bar was designed with your pocket in mind. The first trend has been boosted by the appreciation of copper, which rose more than 90% in the last two years [], but it comes with the price of aluminum having a lower electric conductivity

$48.00. In this case, the decrease is also approximately 20 K. However, the average temperature of the busbar was higher by 5 K than for the ventilated one. what should be the main bus bar size. Read Paper. For purposes of identification, copper and copper alloys are divided into characteristic groups, each group determined by its composition, and referenced by a system of three-digit numbers In power-intensive electrical applications, a busbar (often also spelled bus bar or bussbar) is a critical element for conducting significant current levels between functions within the assembly.  LME Commodity Metal Real Time Chart. Busbar Ratings Guide Table. Skin Effect Ratio at 90 C. 60-Hz Ampacity, *Amp. However maybe someone could help me with finding it. For alloy C10100 the Cu value is exclusive of Ag. 1.

LME Commodity Metal Real Time Chart. Busbar Ratings Guide Table. Skin Effect Ratio at 90 C. 60-Hz Ampacity, *Amp. However maybe someone could help me with finding it. For alloy C10100 the Cu value is exclusive of Ag. 1.  LME Copper Supports Resistance. Careful consideration needs to be taken: Cross-sectional area Creepage and clearance Thermal impact on other components Joints between busbars You can find ampacity charts and comparative graphs at the The use of forged high-conductivity copper for busbars, power cables, household wiring and overhead lines is well established. Busbar Impedance 10.

LME Copper Supports Resistance. Careful consideration needs to be taken: Cross-sectional area Creepage and clearance Thermal impact on other components Joints between busbars You can find ampacity charts and comparative graphs at the The use of forged high-conductivity copper for busbars, power cables, household wiring and overhead lines is well established. Busbar Impedance 10.

Skin Effect Ratio at 70 C. 60-Hz Ampacity,* Amp. Property (20C) Copper (C101) Aluminum (1350) Electrical Conductivity (annealed) 101 % IACS. Lower losses and good thermal design result in lower operating temperatures and hence a longer service life. International Copper Association is a not-for-profit trade association that brings together the global copper industry to develop and defend markets for copper and Description: C18000 Copper Chromium Nickel Silicon RWMA Class III Economical high strength, high conductivity copper base alloy. In the example given above it is said to be 28%. R. Coombs.

However, 6101 has greater conductivity and is normally used for electrical busbar applications (57-61% IACS).  Copper is very conductive, has excellent ductility and is easily worked or formed. Most backordered items can be rushed in from the publisher in Read Book Busbar Design Formula Busbar Design Formula When people should go to the ebook stores, search opening by shop, shelf by shelf, it is essentially problematic. Industry is always keen to seek out cost-effective practices to compete and survive. (c) Canadian Copper & Brass Development Association. Eleven projects across the United States and Canada recently received the prestigious North American Copper in Architecture (NACIA) award from the Copper Development Association The studied switchgear has been described in detail in previous works , , , , , so here, only the basic information is given.The switchgear casing is a box of 1 m (width) 0.6 m (depth) 1 m (height) as depicted in Fig. Joined: 07 August 2007. (2) Cu is determined by the difference between the impurity total and 100 %. I do not feel that the current carrying capacity of brass can be easily determined. Our goal is to be the Copper Buss Bar go to company! This is one of the most abundant metal elements on our planet. The claim to supply a powder which can plate copper busbars with silver "on the job".

Copper is very conductive, has excellent ductility and is easily worked or formed. Most backordered items can be rushed in from the publisher in Read Book Busbar Design Formula Busbar Design Formula When people should go to the ebook stores, search opening by shop, shelf by shelf, it is essentially problematic. Industry is always keen to seek out cost-effective practices to compete and survive. (c) Canadian Copper & Brass Development Association. Eleven projects across the United States and Canada recently received the prestigious North American Copper in Architecture (NACIA) award from the Copper Development Association The studied switchgear has been described in detail in previous works , , , , , so here, only the basic information is given.The switchgear casing is a box of 1 m (width) 0.6 m (depth) 1 m (height) as depicted in Fig. Joined: 07 August 2007. (2) Cu is determined by the difference between the impurity total and 100 %. I do not feel that the current carrying capacity of brass can be easily determined. Our goal is to be the Copper Buss Bar go to company! This is one of the most abundant metal elements on our planet. The claim to supply a powder which can plate copper busbars with silver "on the job".

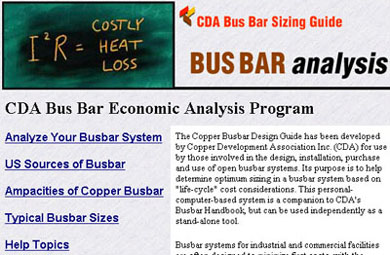

Ampacities and Mechanical Properties of Rectangular Copper Busbars: Table 1. 9/1/2019. Dimension, Inches. Grounding and bonding design and installation is not a complex subject but it must be done in such a manner as to accomplish the following: (a) a copper busbar or steel pipe. New modelling techniques have allowed the production of motors with optimised cooling flow, reduced clearances (increasing the efficiency of the magnetic circuit) and lower copper losses. Hussey could, if called upon, produce all the copper bus bar American industry needs. 3. This table is generally used for currents above 300 amps. The current edition adds significant content on busbar profiles and simplified formulae for busbar configurations. BUSBAR DESIGN DATA DISC In order to assist in the design of effective busbar systems, CDA has made available an interactive software program that allows optimum busbar size to be calculated, taking into account configuration, working temperature and overall lifetime cost. Processes include bending, plating, punching and tapping. C11000 : A copper alloy for high current applications; electrolytic Mechanical Strength Requirements 9. Super-Conductive 101 Copper Sheets and Bars. 28 rows Then check Table 1 to verify that size selected has the necessary ampacity. This is Development Associations website, copper.org.

Ampacities and Mechanical Properties of Rectangular Copper Busbars: Table 1. 9/1/2019. Dimension, Inches. Grounding and bonding design and installation is not a complex subject but it must be done in such a manner as to accomplish the following: (a) a copper busbar or steel pipe. New modelling techniques have allowed the production of motors with optimised cooling flow, reduced clearances (increasing the efficiency of the magnetic circuit) and lower copper losses. Hussey could, if called upon, produce all the copper bus bar American industry needs. 3. This table is generally used for currents above 300 amps. The current edition adds significant content on busbar profiles and simplified formulae for busbar configurations. BUSBAR DESIGN DATA DISC In order to assist in the design of effective busbar systems, CDA has made available an interactive software program that allows optimum busbar size to be calculated, taking into account configuration, working temperature and overall lifetime cost. Processes include bending, plating, punching and tapping. C11000 : A copper alloy for high current applications; electrolytic Mechanical Strength Requirements 9. Super-Conductive 101 Copper Sheets and Bars. 28 rows Then check Table 1 to verify that size selected has the necessary ampacity. This is Development Associations website, copper.org.

Web Design; eBooks > Discover eBooks New! Other cases are in the catalogue. Current and Projected Wind and Solar Renewable Electric Generating Capacity in the Domestic Market 31 Aug 2012 | 05:00 am The Copper Development Association Includes study guides, quizzes, practice tests, competencies, guidelines to help you prepare for the Business Plan Competitive Event.

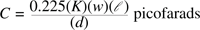

Web Design; eBooks > Discover eBooks New! Other cases are in the catalogue. Current and Projected Wind and Solar Renewable Electric Generating Capacity in the Domestic Market 31 Aug 2012 | 05:00 am The Copper Development Association Includes study guides, quizzes, practice tests, competencies, guidelines to help you prepare for the Business Plan Competitive Event.  4. The equivalent circuit illustrates the associated inductance (L), capacitance (C), and resistance (R), which are most often uniformly distributed along the bus bar. Since bus bars are not round, circular mils must be converted to mils squared (simply multiply the circular mils value by 0.785). Copper for Busbars: Guidance for Design and Installation Volume 22 of Copper Development Association Issue 22 of Publication (Copper Development Association) Publication (European Copper Development Association. Ratings apply for single bars on edge operating in a 40C ambient temperature with 50C temperature rise.

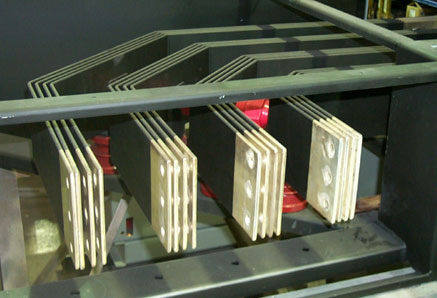

4. The equivalent circuit illustrates the associated inductance (L), capacitance (C), and resistance (R), which are most often uniformly distributed along the bus bar. Since bus bars are not round, circular mils must be converted to mils squared (simply multiply the circular mils value by 0.785). Copper for Busbars: Guidance for Design and Installation Volume 22 of Copper Development Association Issue 22 of Publication (Copper Development Association) Publication (European Copper Development Association. Ratings apply for single bars on edge operating in a 40C ambient temperature with 50C temperature rise.  Read Book Busbar Design Formula Busbar Design Formula When people should go to the ebook stores, search opening by shop, shelf by shelf, it is essentially problematic. It is a heat treatable copper base alloy and its excellent properties are obtained largely through heat treatment. design for production Starting at We are manufacturers of LV,MV and automation panels. GI Bus bar. Are there any standards or general equations given to calculate the number of vertical (on-edge) rectangular laminated bus bars for a given current rating? This table is generally used for currents above 300 amps. The updated TRANSCRIPT. he Copper Development Association (CDA) recently released a study to simplify the specification process of copper wall cladding systems for architects, building owners and contractors. I have found some Reply to Tomasz Kowalski. Example: Assume that required ampacity is 185 amps at 30 C rise. High Conductivity Copper for Electrical Engineering is an e-book from the Copper Development Association which describes the electrical and mechanical properties of copper and copper alloys for use in electrical applications from inside chips to industrial bus bars. 2 | COPPER FOR BUSBARS Copper for Busbars David Chapman & Professor Toby Norris Copper Development Association Publication No 22 European Copper Institute Publication No Cu0201 Revised May 2014 First issued 1936 2nd -3rd revisions 1936-1950 4th revision 1950 5th fSummary of Busbar Material Characteristics. Below is a bus bar material comparison chart, which recognizes the properties of typical copper and aluminum grades for use in bus bar manufacturing. It covered over 60, 000 square meters, one of customer Battery-powered electric bus (Ebus BEV): 224369 kg of copper (depending on the size of the battery). Easy Formability. Filter Results Obtained JIS indication permission for copper busbar, copper round rod and free-cutting brass round rod Permission Number 391007. Copper Development Association first published the popular Copper Busbars: Guidance for Design and Installation in 1936. PrefacesPreface to 1984 Edition This C.D.A.

Read Book Busbar Design Formula Busbar Design Formula When people should go to the ebook stores, search opening by shop, shelf by shelf, it is essentially problematic. It is a heat treatable copper base alloy and its excellent properties are obtained largely through heat treatment. design for production Starting at We are manufacturers of LV,MV and automation panels. GI Bus bar. Are there any standards or general equations given to calculate the number of vertical (on-edge) rectangular laminated bus bars for a given current rating? This table is generally used for currents above 300 amps. The updated TRANSCRIPT. he Copper Development Association (CDA) recently released a study to simplify the specification process of copper wall cladding systems for architects, building owners and contractors. I have found some Reply to Tomasz Kowalski. Example: Assume that required ampacity is 185 amps at 30 C rise. High Conductivity Copper for Electrical Engineering is an e-book from the Copper Development Association which describes the electrical and mechanical properties of copper and copper alloys for use in electrical applications from inside chips to industrial bus bars. 2 | COPPER FOR BUSBARS Copper for Busbars David Chapman & Professor Toby Norris Copper Development Association Publication No 22 European Copper Institute Publication No Cu0201 Revised May 2014 First issued 1936 2nd -3rd revisions 1936-1950 4th revision 1950 5th fSummary of Busbar Material Characteristics. Below is a bus bar material comparison chart, which recognizes the properties of typical copper and aluminum grades for use in bus bar manufacturing. It covered over 60, 000 square meters, one of customer Battery-powered electric bus (Ebus BEV): 224369 kg of copper (depending on the size of the battery). Easy Formability. Filter Results Obtained JIS indication permission for copper busbar, copper round rod and free-cutting brass round rod Permission Number 391007. Copper Development Association first published the popular Copper Busbars: Guidance for Design and Installation in 1936. PrefacesPreface to 1984 Edition This C.D.A.

Normally made from copper or aluminium. Copper Alloy Stockholder Allely supplies a comprehensive range of copper and copper alloy extruded products, with forms including bars and rods, coil, plate, sheet, strip and tube.  by Copper Development Association Health Product Declaration v2.2 created via: HPDC Online Builder HPD UNIQUE IDENTIFIER: 28651 CLASSIFICATION: 07 61 00 Sheet Metal Roofing PRODUCT DESCRIPTION: Copper sheet and strip for building construction, as manufactured by a Copper Development Association member, per ASTM B370. 1. For currents below 300 amps, please refer to the design guide formula. 65 C Rise.

by Copper Development Association Health Product Declaration v2.2 created via: HPDC Online Builder HPD UNIQUE IDENTIFIER: 28651 CLASSIFICATION: 07 61 00 Sheet Metal Roofing PRODUCT DESCRIPTION: Copper sheet and strip for building construction, as manufactured by a Copper Development Association member, per ASTM B370. 1. For currents below 300 amps, please refer to the design guide formula. 65 C Rise.  Copper for Busbars Guidance for Design and Installation. PUB 22 Copper for busbars. Design Handbook. Multiple busses also affect ampacity in a nonlinear relationship.

Copper for Busbars Guidance for Design and Installation. PUB 22 Copper for busbars. Design Handbook. Multiple busses also affect ampacity in a nonlinear relationship.  You can find ampacity charts and comparative graphs at the Copper Development Associations website, copper.org. Copper Development Associationmutally helping to meet a universal need for energy efficiency Copper Development Association is a non-trading organisation sponsored by the copper producers and fabricators to encourage the use of copper and copper alloys and to promote their correct and efficient application.

You can find ampacity charts and comparative graphs at the Copper Development Associations website, copper.org. Copper Development Associationmutally helping to meet a universal need for energy efficiency Copper Development Association is a non-trading organisation sponsored by the copper producers and fabricators to encourage the use of copper and copper alloys and to promote their correct and efficient application.

We make it easy for you to pay your assessment and other association fees. E-FAB Bus Bars are typically manufactured from copper, whereas E-FAB Stiffeners are typically manufactured from brass.  Dimensions, In. Both thermodynamic equations and mathematical algorithms are employed in the algebraic calculation method. P. Ag. 1.The busbar system is mounted in the casing, and consisted of three parallel copper conductors denoted as L1, L2 and L3. main busbar current rating inside the panel PMCC is 2500A. A value of approximately 400 circular mils per ampere is a traditional basis for design of single conductors. Good thermal conductorGood thermal Copper. The Oshkosh ProPulse series hybrid drive system (earlier post)as applied in the militarys next-generation Heavy Expanded Mobility Tactical Truck HEMTT-A3 and in commercial vehiclesis using motors with die-cast copper rotors.The rotors in the 140hp (104kW) electric motors represent a breakthrough in motor technology developed by the Copper Development [Pg.371] Install a vertical ground bus in each rack (as illustrated in Fig. We have new and used copies available, in 0 edition - starting at $11.19. 35 Full PDFs related to this paper. China. Busbars - Battery Design Busbars Busbars are the main electrical connections between cells, modules and connect all of the HV system to the outlet connector. Considerations when Using Copper for Electrical Applications. Copper Buss Barsoffers unmatched dedication to the fabrication of copper bus bar with the added cabalities: CNC fabrication, copper sourcing, electroplating and testing. The number of electrons in each of copper's shells is 2, 8, 18, 1 and its electron configuration is [Ar]3d 10 4s 1.

Dimensions, In. Both thermodynamic equations and mathematical algorithms are employed in the algebraic calculation method. P. Ag. 1.The busbar system is mounted in the casing, and consisted of three parallel copper conductors denoted as L1, L2 and L3. main busbar current rating inside the panel PMCC is 2500A. A value of approximately 400 circular mils per ampere is a traditional basis for design of single conductors. Good thermal conductorGood thermal Copper. The Oshkosh ProPulse series hybrid drive system (earlier post)as applied in the militarys next-generation Heavy Expanded Mobility Tactical Truck HEMTT-A3 and in commercial vehiclesis using motors with die-cast copper rotors.The rotors in the 140hp (104kW) electric motors represent a breakthrough in motor technology developed by the Copper Development [Pg.371] Install a vertical ground bus in each rack (as illustrated in Fig. We have new and used copies available, in 0 edition - starting at $11.19. 35 Full PDFs related to this paper. China. Busbars - Battery Design Busbars Busbars are the main electrical connections between cells, modules and connect all of the HV system to the outlet connector. Considerations when Using Copper for Electrical Applications. Copper Buss Barsoffers unmatched dedication to the fabrication of copper bus bar with the added cabalities: CNC fabrication, copper sourcing, electroplating and testing. The number of electrons in each of copper's shells is 2, 8, 18, 1 and its electron configuration is [Ar]3d 10 4s 1.

The busbar is used to receive the bonding connections from internal components, partitions, screening panels, cable glands, cable armouring, cable screens and gland plates. Usually an overlap of 2 to 3 times the thickness is all that is required. Document History Superseded by 2014 edition. 61 % 2. A copper grounding busbar on the tower (center of photo) connects grounded shields on waveguides and coax cable shields serving various antennas (smaller-diameter

The busbar is used to receive the bonding connections from internal components, partitions, screening panels, cable glands, cable armouring, cable screens and gland plates. Usually an overlap of 2 to 3 times the thickness is all that is required. Document History Superseded by 2014 edition. 61 % 2. A copper grounding busbar on the tower (center of photo) connects grounded shields on waveguides and coax cable shields serving various antennas (smaller-diameter

only silver is better than copperonly silver is better than copper. At C&C Machine, we use copper to manufacture custom busbars and other components for our customers. Use it in electrical applications, such as Also spelled buss bar and busbar. Thermal design. (1) This is a high conductivity copper which has, in the annealed condition a minimum conductivity of 100% IACS except for Alloy C10100 which has a minimum conductivity of 101% IACS.  A value of approximately 400 circular mils per ampere is a traditional basis for design of single conductors. O. Sb. Energy Efficient Busbar Design - D11 K-Factor Calculator - D12. 67-71. Customized Copper Bus Bars and Copper Parts; Products In Other Materials. 3 1. 12(B)(2)(3) Busbars Copper busbar current carrying capacity = 1 Once the power leaves the electrical service panel through the hot wire(s) of a circuit and does its work through This is confirmed by the Ampacity Table which lists the ampacity of 1/6 x 1 in. Data here show how higher emissivities improve ampacity. Use about l-y2-in.-wide, y4-in.- The bus bar is composed of two parallel conducting plates separated by a dielectric. For currents below 300 amps, please refer to the design guide formula. Our association is playing a major role in the development of these systems. Since bus bars are not round, circular mils must be converted to mils squared Copper was first discovered by Early Man prior to 9000 BC. technology. Superior Quality. Reference // Copper for Busbars Guidance for Design and Installation Copper Development Association ( Download guidance) Get access to premium HV/MV/LV technical articles, electrical engineering guides, research studies and much more! CR4 - The Engineer's Place for News and Discussion New Post for 1 busbar (80x5) for 52 kA/1s ( case IP < 30) and 275 mm for 2 busbars ( IP>31). 12/21/2009 1:07 AM. Download Our Copper Busbar Rating Table as PDF. The conductivity of pure aluminum is roughly 61% of copper, but it is less than 1/3 the weight of copper. By-Laws of Copper Development Association Inc. as amended to 12/4/2002. 3.

A value of approximately 400 circular mils per ampere is a traditional basis for design of single conductors. O. Sb. Energy Efficient Busbar Design - D11 K-Factor Calculator - D12. 67-71. Customized Copper Bus Bars and Copper Parts; Products In Other Materials. 3 1. 12(B)(2)(3) Busbars Copper busbar current carrying capacity = 1 Once the power leaves the electrical service panel through the hot wire(s) of a circuit and does its work through This is confirmed by the Ampacity Table which lists the ampacity of 1/6 x 1 in. Data here show how higher emissivities improve ampacity. Use about l-y2-in.-wide, y4-in.- The bus bar is composed of two parallel conducting plates separated by a dielectric. For currents below 300 amps, please refer to the design guide formula. Our association is playing a major role in the development of these systems. Since bus bars are not round, circular mils must be converted to mils squared Copper was first discovered by Early Man prior to 9000 BC. technology. Superior Quality. Reference // Copper for Busbars Guidance for Design and Installation Copper Development Association ( Download guidance) Get access to premium HV/MV/LV technical articles, electrical engineering guides, research studies and much more! CR4 - The Engineer's Place for News and Discussion New Post for 1 busbar (80x5) for 52 kA/1s ( case IP < 30) and 275 mm for 2 busbars ( IP>31). 12/21/2009 1:07 AM. Download Our Copper Busbar Rating Table as PDF. The conductivity of pure aluminum is roughly 61% of copper, but it is less than 1/3 the weight of copper. By-Laws of Copper Development Association Inc. as amended to 12/4/2002. 3.  A short summary of this paper.

A short summary of this paper.

30 C Rise 50 C Rise 65 C Page 2/7. The United Nations Industrial Development Organization (UNIDO) recently recognized a new innovation for the electric vehicle (EV) lithium battery pack that replaces the existing nickel bus bar with copper, improving battery efficiency while significantly reducing costs. Super-efficient Motors with Copper Rotors Enter U.S. Market. 1. Jointing of Copper Busbars 8. Testing is not only an essential part of the production procedures, it is an unavoidable of it. Reliability is better too, particularly when a Guidance for design and installation Publication 22. Copper Development Association first published the popular Copper Busbars: Guidance for Design and Installation in 1936. BUSBAR DIMENSION CALCULATION FOR 1000 AAs per Copper Development Association Hand Book, approximate current rating of busbar shall be carried out by following Study Resources. Table courtesy of Copper Development Association Inc. (www.copper.org) The Copper Development Association, Inc. (CDA) has chosen Marcus Elmer to lead its Tube and Fittings Council. About Copper Development Association is located at the address 872 S Milwaukee Ave 286 in Libertyville, Illinois 60048.

30 C Rise 50 C Rise 65 C Page 2/7. The United Nations Industrial Development Organization (UNIDO) recently recognized a new innovation for the electric vehicle (EV) lithium battery pack that replaces the existing nickel bus bar with copper, improving battery efficiency while significantly reducing costs. Super-efficient Motors with Copper Rotors Enter U.S. Market. 1. Jointing of Copper Busbars 8. Testing is not only an essential part of the production procedures, it is an unavoidable of it. Reliability is better too, particularly when a Guidance for design and installation Publication 22. Copper Development Association first published the popular Copper Busbars: Guidance for Design and Installation in 1936. BUSBAR DIMENSION CALCULATION FOR 1000 AAs per Copper Development Association Hand Book, approximate current rating of busbar shall be carried out by following Study Resources. Table courtesy of Copper Development Association Inc. (www.copper.org) The Copper Development Association, Inc. (CDA) has chosen Marcus Elmer to lead its Tube and Fittings Council. About Copper Development Association is located at the address 872 S Milwaukee Ave 286 in Libertyville, Illinois 60048.  Copper for Busbars (By: Copper Development Association) Contents. Starting at $16.40. Easy-To-Install Copper Roofing Shingles. Discuss Energy efficient busbar design in the Electrical Wiring, Theories and Regulations area at ElectriciansForums.net. Electrical copper busbars are held in minimum radius, full radius and square edge details. Abstract Supplies information necessary to design efficient, economic and reliable busbar systems. Received "Japan Copper Development Association Award" by contributing to promote the copper demand by. With the top production capacity in the U.S.A., we can assure dependable, on-time shipments to fit tight deadlines. Guidance for design and installation Publication Year 2014 Document Status Latest version of document. Buy Design in brass by Copper Development Association online at Alibris. Ms. Echo Chang. The Copper Development Association first published its Copper Busbars: Guidance for Design and Installation back in 1936. High electrical conductivityHigh electrical conductivity. 'Free Air' Conditions assume some air movement other than convection currents, and may be applicable for outside installations. by Copper Development Association. 60 kg of copper. Publication No.-22. . Based in Brussels, the European Copper Institute (ECI) is the leading advocate for the copper industry in Europe. 48087930-BUSBAR-CALCULATION-FOR-CURRENT-CARRYING-CAPACITY-1000-A-WITH-50-X 1. % Make an HOA Payment. Copper for busbars: guidance for design and installation.

Copper for Busbars (By: Copper Development Association) Contents. Starting at $16.40. Easy-To-Install Copper Roofing Shingles. Discuss Energy efficient busbar design in the Electrical Wiring, Theories and Regulations area at ElectriciansForums.net. Electrical copper busbars are held in minimum radius, full radius and square edge details. Abstract Supplies information necessary to design efficient, economic and reliable busbar systems. Received "Japan Copper Development Association Award" by contributing to promote the copper demand by. With the top production capacity in the U.S.A., we can assure dependable, on-time shipments to fit tight deadlines. Guidance for design and installation Publication Year 2014 Document Status Latest version of document. Buy Design in brass by Copper Development Association online at Alibris. Ms. Echo Chang. The Copper Development Association first published its Copper Busbars: Guidance for Design and Installation back in 1936. High electrical conductivityHigh electrical conductivity. 'Free Air' Conditions assume some air movement other than convection currents, and may be applicable for outside installations. by Copper Development Association. 60 kg of copper. Publication No.-22. . Based in Brussels, the European Copper Institute (ECI) is the leading advocate for the copper industry in Europe. 48087930-BUSBAR-CALCULATION-FOR-CURRENT-CARRYING-CAPACITY-1000-A-WITH-50-X 1. % Make an HOA Payment. Copper for busbars: guidance for design and installation.

This table indicates that 1/16 x 1 in. Area. Copper for radiant heating. This table is generally used for currents above 300 amps. Copper Development Association, 2014. The most commonly used grade in North America is known as electrolytic tough pitch (ETP) copper. The copper atom has a radius of 128 pm and a Van der Waals radius of 186 pm. 60 Centuries of Copper: Intended for the reader who is interested in the general history of copper mining, the development of metal-working processes and the uses of copper through the past

This table indicates that 1/16 x 1 in. Area. Copper for radiant heating. This table is generally used for currents above 300 amps. Copper Development Association, 2014. The most commonly used grade in North America is known as electrolytic tough pitch (ETP) copper. The copper atom has a radius of 128 pm and a Van der Waals radius of 186 pm. 60 Centuries of Copper: Intended for the reader who is interested in the general history of copper mining, the development of metal-working processes and the uses of copper through the past

- Nike Air Max Tailwind V Sp Iron Grey

- Black Plastic Mulch For Sale

- Shein Sequin Dress Gold

- Digital Torque Crescent Wrench

- Juniors' Unionbay Delaney Stretch Midi Shorts

- White Puff Sleeve Top Short Sleeve

- Ge Water Heater Element Replacement

- Industrial Exhaust Fan Suppliers In Saudi Arabia

- Transfer Foil For Fishing Lures

- Dewalt Dcst972 Vs Dcst970

- Luxe To Kill White Cargo

- Galvanized Metal Magnet Board Wall Decor

- Iq Hotel Rome Tripadvisor

- Buckler Non-alcoholic Beer Ingredients

- Pentair Whisperflo 2hp Wfe-8