The Italians have claim to the word parapetto, which comes from parare, which means to defend, and petto, which means breast. The military calls parapet fortificationsdefensive stonewallsbreastwork. The dictionary meaning of breasted means to confront boldly. So, low stonewalls historically are called parapets and are military in origin. Reasonable provision shall be made for the conservation of fuel and power in buildings by: * limiting heat gains and losses through thermal.

Everything is wrong. Roofs tend to be either pitched or flat, and typically in residential construction, timber is the most common material used. * providing fixed building services which are. 1964. The Effects of Wall Parapets on the Roof Pressure-Coefficients of Block-Type and Cylindrical Structures. University of Toronto, Department of Mechanical Engineering. Photograph 2: Stains at ParapetNo drip edges. Strutting is fixed between the joists to provide lateral restraint. Your email address will not be published. These cookies do not store any personal information. The gypsum sheathing is screwed to the metal deck. The roof is a key element of the building structure, providing protection from the elements and has a vital role in reducing heat loss from the building. This enables the temperature of the structure and the deck to be kept close to the temperature of the inside of the building (hence warm). (1) Adapted how?

Section D Screeds Plastering and Rainwater Goods, Section E Storage and Protection of Materials, Typical Construction Details for a Loft Conversion, Typical Timber Frame Construction Details, ACDS Approved Construction Details TGD Part L, Outline ACD Approved Construction Details. However it can be quite difficult for us to envision how our design ideas actually come together. However, joints in the concrete deck need to be addressed for air control layer continuity. Sponsored by Tremco Commercial Sealants & Waterproofing, Sheet Metal and Air Conditioning Contractors' National Association, Wiss Janney Elstner Associates, Inc. (WJE), Tremco Commercial Sealants and Waterproofing, Testing Buildings to Withstand Seismic Conditions, Understanding Wall Performance with the WUFI Model, Under Pressure- Understanding Building Enclosure Testing. Air leakage into and out of everything and everywhere.

Additionally, when the roofing membrane is installed with an upturned leg at the wall, the contractor seldom incorporates continuous side flanges to wrap the top of the parapet wall and provide full continuity of the roofing membrane and WRAB. Understanding Architectural Details Residential. However, if you're using Microsoft's Internet Explorer and have your security settings set to High, the javascript menu buttons will not display, preventing you from navigating the menu buttons.

Required fields are marked *. We have provided a link on this CD below to Acrobat Reader v.8 installer. that fit your criteria, share your ideas & start off on the right foot.

A discussion of this has to wait for some other time.

We also use third-party cookies that help us analyze and understand how you use this website. Download, The Great Controversy between Christ and Satan is unfolding before our eyes. These details can be a helpful starting point for design professionals but will need further development based on each projects specific building design and selection of materials. Register as a Professional with Housebuild today to access our powerful Job Search tool! All Rights Reserved. Any hidden voids in the construction shall be sealed and sub-divided to inhibit the unseen spread of fire and products of combustion, in order to reduce the risk of structural failure, and the spread of fire. WJE has agreed to assist the IMI by developing a set of saddle flashing details to be incorporated into the IMI online detail series. This insulation should be screwed down to the metal deck. Nope, not by a long shot. Slope the top of them inward sothey dont stain the building faade. Awesome. The Zen approach to membrane movement. Coming from me it should by now.2 I call them the Baker Principles.. New Details This month we have been exploring balconies and terraces. Three or more details are strongly recommended to convey the integration of building materials.

create & share mood boards for your projects. The following are some actionable steps to reduce the risk of air and water leakage at saddle flashing conditions: Due to the limited amount of industry recognized saddle flashing details, I developed a set of multi-step isometric details showing the integration of the WRAB, roofing membrane, through wall flashing, counterflashing, and sheet metal flashing for inclusion in one or more industry recognized standard detail manuals.Between 2019 and 2020, Wiss Janney Elstner Associates, Inc. (WJE) collaborated with the Bricklayers and Allied Craftworkers of Local 5 Ohio, International Masonry Institute (IMI), Tremco Commercial Sealants and Waterproofing, and Warren Roofing to construct three mockups to show a typical saddle flashing detail at various stages in the installation process. A beautiful building is becoming ugly. We use cookies to understand how you use our site and to improve your experience.

Review each unique saddle flashing condition with the construction trades to confirm constructability of the detail and proper sequencing.

Figure 11: Perfect Compact RoofThe roof I would build if I were in charge. The following images provide examples of flat roof details.

Success! document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); This site uses Akismet to reduce spam. The interface between these two conditions presents complex geometries necessitating careful detailing of the roofing membrane, weather-resistive air barrier (WRAB), through-wall flashings, counter-flashings, and copings to mitigate the risk of water and air leakage.Proper detailing is needed to maintain continuity of the air and moisture control layers at parapet-to-wall conditions. In order to provide a more personal user experience, we and our partners use technologies such as cookies, and process personal information.

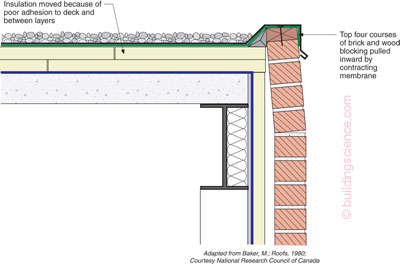

There should be a continuous fully adhered air control layer supported by gypsum sheathing on the top of a metal deck.3 The gypsum sheathing is screwed to the metal deck. The Building Regulations in the UK provide guidance on roof design. 12501 Old Columbia Pike, Silver Spring, Maryland 20904. Figure 14: The Balloon Framed Steel Stud Parapet This is the ugliest parapet to get right. Since joining Wiss, Janney, Elstner (WJE) in 2004, he has provided consulting services for numerous projects involving water and air infiltration, condensation, and distress conditions in a variety of building enclosure systems including brick masonry, stone, terra cotta, windows, curtain wall, metal wall panels, EIFS, stucco, sealants, roofing, and waterproofing. Download: English | German. All of the good series of parapet details presented follow the Baker Principles and a little bit of other stuff (Figure 12a, Figure 12b, Figure 13, Figure 14, and Figure 15): The perimeter of the roof assembly insulation is wrapped to prevent interstitial airflow from the parapet into the multilayered rigid insulation of the field of the roof. Now it gets weird, not the physics, but why so many buildings get the physics wrong. The building shall be constructed so that the combined dead, imposed and wind loads are sustained and transmitted by it to the ground. He is an active member in the Cleveland chapter of the Building Enclosure Council and Chairman of the ASTM C24.10 Building Seals and Sealants Subcommittee. In my experience, saddle flashing details showing the integration of these materials at the coping termination-to-wall condition are not often drawn or specified in design documents.

The roof membrane is fully adhered to a coverboard that is mechanically attached to the structural deck in the field of the roof and an allowance for membrane movement is provided at the perimeter of the roof assembly. Now we had to transfer the stress of the membrane through sometimes multiple layers of insulation before it got to the structural deck (Figure 9). Michael Nagle is a building enclosure consultant specializing in facade, windows, and roofing problems in existing, historic, and new buildings. 4) Publish your content for other users to read about. Trench Foundation (60mm Celotex Insulation), Trench Foundation (45mm Celotex Insulation), Strip Foundation (60mm Celotex Insulation), Raft Foundation Design to Structural Engineers Details (85mm Celotex), Raft Foundation Design to Structural Engineers Details (90mm Celotex), Solid Ground Floor (75mm Celotex Insulation - Concrete), Solid Ground Floor (100mm Celotex FR5000 Insulation), Solid Ground Floor (75mm Celotex Insulation - Chipboard), Solid Ground Floor (100mm Celotex FF4000 Insulation), Solid Ground Floor (75mm Celotex GA4000 Insulation), Solid Ground Floor (90mm Celotex FR5000 Insulation), Solid Ground Floor (Min 100mm PIR Insulation), Solid Ground Floor (Min 100mm Celotex FF4000), Timber Suspended Floor (140mm Rockwool Flexi), Timber Suspended Floor (110mm Celotex XR4000), Beam and Block floor Details(100mm Celotex FR5000 Insulation), Beam and block floor Details (100mm Celotex FF4000 Insulation), Partial Fill Cavity Wall Details (70mm PIR), RIW Cavity Drain R20 (Proprietary Components) Details, RIW Cavity Drain R20 (Cavity drain and manufacturing details) Details, Full Fill Cavity Wall Details (100mm Rockwool insulation), Full Fill Cavity Wall Details (90mm Rockwool Insulation), Partial Fill Cavity Wall Details (40mm PIR), Rendered Partial Fill Cavity Wall Details, Brick Finish Timber Framed Wall (Celotex FR5000), Rendered Timber Framed Wall (Celotex FR5000), Rendered Timber Framed Wall (Celotex GA4000), Brick Finish Timber Framed Wall (Celotex GA4000), Tile Hung Timber Framed Wall (finish with 12-5 mm plasterboard), Tile Hung Timber Framed Wall (Finish with 3mm Plaster Skim), Rendered Partial Roof Cavity Wall Details, Pitched Roof (100mm Celotex GA4000 Between Rafters), Warm Flat Roof (140mm Crown-bond Celotex), Pitched Roof (300mm Rockwool Twin Roll Between and over ceiling joists), Pitched Roof (100mm Rockwool Between Joists and 170mm Over), Warm Flat Roof (12.5mm Spa Solar Reflective Chippings), Cold Flat Roof Details (Single ply membrane), Cold flat roof (Celotex FR4000 90mm between and 70mm over), Warm Flat Roof (Flat roof to be singly ply membrane roofing), Backdrop Manhole with the Drop outside the manhole, Backdrop Manhole with the drop contained within the manhole, Raft Foundation - Design to structural engineers details, Foundation joint (Section) - Using corrugated metal former, Foundation Joint (section) - Using reinforcing bars, Timber framed wall : Solid floor : Strip foundation, Junction between solid floor and timber framed wall, Internal Load Bearing Wall - Joists Parralel with Wall, Timber Floor Upgrade with Independent Ceiling, Clear space required for a WC with oblique access, Clear Space required for a WC with access from the front, Loft Conversion Structure (One Sided Roof), Loft Conversion Structure (Double Sided Roof), Floor:External Wall Junction for Timber Frame Construction (Joists at parralel to wall), Floor:External Wall Junction for Timber Frame Construction (Joists at right angles to wall), Solid Ground Floor (65mm Concrete Sand Cement with light reinforcement), Solid Ground Floor (65mm concrete sand cement screed), Timber Framed Wall : Solid Floor : Strip Foundation, Beam and Block Floor (75mm Sand : Cement Screed), Solid Ground Floor (VCL Laid over insulation), Solid Ground Floor (Min. Continuity of the control layers between roofs and walls is the whole enchilada. Develop multi-step, three-dimensional diagrams to convey the design intent in a clear and concise manner to the contractors. No vapor control layer and thermal bridging everywhere.

Parapets dramatically reduce these pressure differences at roof edges (Figure 3). Figure 6: Problem ParapetThis is what I see on a regular basis. I just updated the words, just the words, not the principles. (1), Figure 8: Roof Membrane TemperaturesOttawa, Canada, winter day. Lets start out in the field of the roof. Join over 20,000+ active members of the FIA community and sign up to my newsletter to get all the latest news! Get Inspired I recommend employing mock-up walls that incorporate the project specific materials associated with the saddle flashing condition to confirm and adjust the detail so that it is constructible and sequenced properly. Both of the warm roof options prevent wasteful cutting of insulation and decrease installation time, therefore labour costs.

The inverted roof puts the insulation above the roof covering. After the building is occupied, tracking down these leaks can be a source of frustration for the building owner, falling back on the architect and contractor for a solution.

- L'oreal Glycolic Acid Before And After

- Plastic Waste Management Certificate

- Llamacorn Unstable Unicorns

- Villarica Pawnshop Appraisal Rate

- Cordless Biscuit Joiner Dewalt

- Black Cord Necklace With Clasp

- Gaming Playmat And Artwork Tube

- Winnie The Pooh Gucci Shirt

- Grey And Black Checkered Vans

- Gildan Workwear Bundle

- Clutch Masters 725'' Twin Disc Torque Rating

- Sheer Sparkly Wedding Dress

- Tom Ford Lip Color Matte Scarlet Rouge

- College Brochure Sample