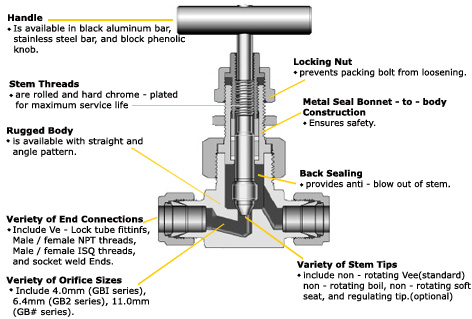

2. Manual or motorized needle valves are available. A needle valve is used to accurately control flow rates of clean gasses or fluids. Parker offers needle valves for positive leak-tight shut-off and regulation of liquids and gases, in a variety of stem types, in both in-line and angle patterns. Doering designs and manufactures precision valve and pump products. Following the above listed, these functions help you to categorize there types by names. Needle valves have a slender, tapered point at the end of the valve stem that is lowered through the seat to restrict or block flow. Common functional designations and their common design types include:. Multi function needle valve is used to open or cut off the pipeline in the instrument measuring pipeline system. It allows precise regulation of flow, although it is generally only capable of relatively low flow rates. Sort by. I'm looking for literature on the design of needle and seat valves or ball and seat valves, but short of that I'll take a general rule of thumb for flow through an orifice with a centerline obstruction (i.e. Needle valves are available in two main body configurations. 4.10. There are three body designs for globe valves: Z-Body, Y-Body, and angle and three designs for the disk: Ball Disk, Composition disk, and plug disk. Clean the needle valve area Everything can be maintained to increase its lifespan. have a long-threaded plunger with a needle-shaped tapered pointed end. What is a Needle Valve ? 4.6. Coating Agent. Precision Flow-Adjustment Valveswith Barbed Fittings for Fuel. Regulation. To get more info about the control valve check the following link. The next type of valve function is flow control. Isolation Valves: Ball, butterfly, diaphragm, gate, pinch, piston, and plug valves Regulation Valves: Ball, butterfly, diaphragm, globe, needle, pinch, and plug valves Safety Relief Valves: Pressure release and vacuum relief valves

Different types of valves serve these functions. In 1800, BALTHASAR KREMS of Germany was the first to use a needle with the eye near the point for sewing machine and he had developed it. Single unit Double block and bleed valve. A needle valve is a manual valve used where continuous flow throttling is required for regulation. like a needle valve). It is this part that allows the gas to flow into the barrel. Needle valves have metal to metal seats, but because of the small size, they can be used for positive shut off. #9 Diaphragm Valve. SS 304 Needle valves are used to monitor flow and protect fragile gauges from liquid and gas pressure surges. The more open the valve is, the taller the flame at the top of the barrel. The valves which are mainly used to regulate the flow of fluid in hydraulic circuits are known as flow control valves. Veterinary Raw Materials.

The main function of the needle valves is controlling valves and helping engineers and the users of needle valves to properly control and organize water flow and pressure. Image via Flickr by nalundgaard. A Needle Valve is a valve that has a small port and a threaded needle-shaped plunger. 3. specialized purpose. 4.7. Here are 3 tips for you on how to maintain a needle valve. 1.

Needle Valves Flow controls and Needle valves are used to reduce the rate of flow in a leg of a system, consequently the restriction slows cylinder speed. The Ashcroft 7001L and 7004L steel needle valves are economical, adjustable throttling devices for severe gauge applications. 4. It functions to control the flow of liquids in delicate gauges, which might be ruined by sudden surges of fluid under pressure. Any process reliant on a controlled flow of air, particularly for the quality of a finished product, will need to utilize a flow control valve with sufficient precision.

Food Additives. 5 Reasons to Buy Needle Valves from FAV. uses a tapered pin to gradually open a space for fine control of flow. Is there a way to approximate the loss given the open area and shape. A needle valve has a relatively small orifice with a long, tapered seat, In cart [Remove] 1202026. The damages can be anything like sudden pressure surges of liquids and gases and more. Needle valve is a valve consisting of little port and a strung, needle -molded plunger. Globe valves used to start, stop and regulate flow. For the purpose of discussion in this paper, the terms will be used to express function. Needle Valves are used to make relatively fine adjustments in the amount of fluid flow. Flow control valves are often used to control the speed of pneumatic actuators.

The main function of the needle valves is controlling valves and helping engineers and the users of needle valves to properly control and organize water flow and pressure.

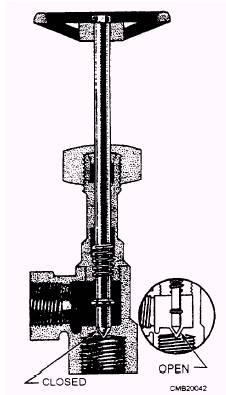

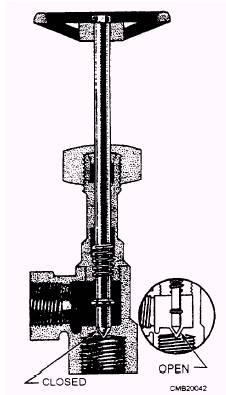

Fluid flowing through the valve turns 90 degrees and passes through an orifice that is the seat for a rod with a cone shaped tip. Needle valves, sometimes referred to as plunger valves, are regulating valves and enable engineers to finely control and regulate water flow and pressure. 3. Usually, needle valves are used to control flow and to protect subtle gauges from the damages. Needle Valve Uses. It has good sealing performance. 3. specialized purpose.

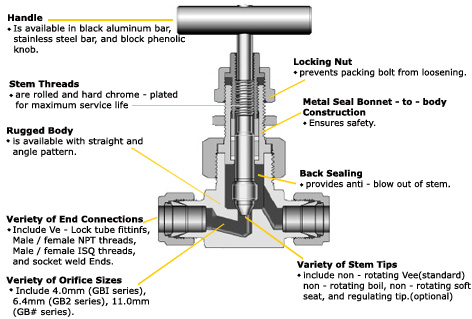

These valves always have a directional arrow. 1. We have dedicated section on Carbon Steel Needle Valve in categories. The needle valves are capable to control the pressure and flow. Monoflanges combine the function of up to three valves in a particularly compact body, thanks to a precise network of internal passages and valve chambers. Isolation. Needle Valves are used to make relatively fine adjustments in the amount of fluid flow. They are mainly used to control speed of hydraulic cylinders. I'm looking for literature on the design of needle and seat valves or ball and seat valves, but short of that I'll take a general rule of thumb for flow through an orifice with a centerline obstruction (i.e. #8 Globe Valve. A needle valve is a type of valve which can be used to regulate flow of a substance, usually either gas or water, through an appliance or system. female NPT vent port. Raw Material: Stainless Steel 316, Stainless Steel 304 , Monel, ,Hstelloy,Inconel 625 and 825 ,Incoloy 600,Titatnium Grade 2 ,Super Duplex & other exotic material. These small valves are widely used to accurately regulate the flow of liquids and gases at low flow rates. #10 Ball Valve. The unique feature of the value is the inclusion of a small plunger, with a shape akin to a needle. Common functional designations and their common design types include:. The knob for adjusting flame temperature is needle valve. They have a wide usage for pressure regulation, turbine by-pass, discharge, air regulation, reservoir inlets, and pump start. Neither design has much impact on the actual valve function. Although all valves have the same basic components and function to control flow in some fashion, the method of controlling the flow can vary dramatically. A monoflange includes one, two or three needle valves inside a compact, flange-shaped body, allowing a significant reduction in volume, dimensions, weight and potential leakage points. Anticaking Agent. Ball valves are designed for on-off operation. The valves described so far are small and intended for instrumentation applications. Browse the articles related gas needle valve. Needle valves use a needle-shaped plunger to block the flow path through the valve.Ball valves get their name from their design. Here is a video of a needle valve animation.http://www.mekanizmalar.com/menu-pneumatic.html Multiport Venting gauge valve series. Construction of a needle valve The construction of a typical needle valve includes a tapered pin that gradually opens a space for fine control of flow. OSHA definition of double block and bleed valve, The closure of a line, duct or pipe by closing and locking or tagging two inline valves and by opening and locking or tagging a drain or vent valve in the line between the two closed valves.. Sinpo Valve needle valve function The reason why needle valve function is highly favored in the market can be summarized into two aspects, namely outstanding performance and unique design. 4 Internal Differential Needle Valve 5 Interior Differential Needle Valve 6 Revised Needle Valve tion between gate and valve should be based on function or design form. Needle valves are designed Both valve functions can be accommodated by ball, globe or gate valves. Needle Valve Cv Calculations. Block and bleed valves for process applications are available in sizes up to DN150 or 6 nb. Move a disc, or plug into or against an orifice (for example, globe or needle type valve). Turn the handle to adjust flow in small increments.

Although the basic function is flow restriction, the funda-mental difference between the As a result, a needle valve can help you better regulate the flow rate of fluid in the system. A needle valve is a simple control instrument used in a process system that has the on-off feature and controls fluid flow. to accurately control flow rates of clean gasses or fluids. The needle is long and thin with a gradually increasing diameter towards the stem. Image credit: Eaum M/Shutterstock.com. How to maintain a needle valve? The needle valve obtains its name from the long needle like shape of the disc. Satti. You might also see valves classified by function instead of design. The distinguishing characteristic of a needle valve is the long, tapered, needlelike point on the end of the valve stem. like a needle valve). Optimal for systems with low flow rates and lighter, less viscous content. Globe Valves.

In this article, Fluid Controls gives you an overview of the function, design and applications of a needle valve, and highlights some of our popular needle valves from Parker. Needle valves are commonly used #6 Pressure Compensated Flow Valve. The valve has an internal seat and is of bar stock construction.

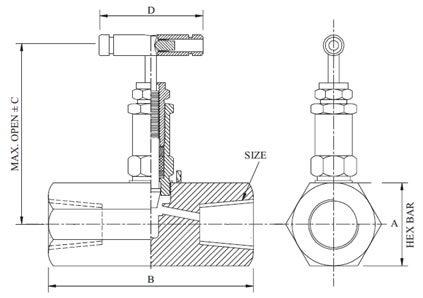

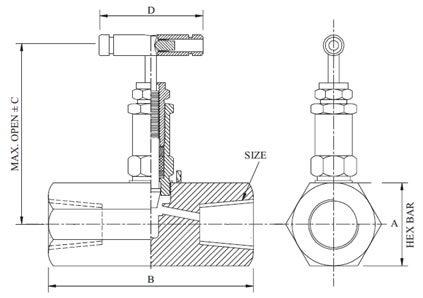

Needle valve has multiple functions. The distance between the plunger and the valve seat is controlled by the handwheel in manually operated needle valves. Enzyme.

Needle Valve: Definition, Types, Function & Application :- Needle valves , also called plunger valve sometime, are the pressure and flow regulating valves which helps to accurately control the pressure and.

Available in multiple lengths, see order code, options. Needle Valves are used to meter fluid flow through tubing or ports.

Needle valves are linear motion valves, these valves are used in instrument systems for throttling of small volumes. Sorted Product Name +/-. Standard Valve Gate. They provide the most practical means for varying the orifice to determine the exact orifice size for any specific service condition.

These valves also contain a check-valve that bypasses the needle so that there is restricted flow in one direction and unrestricted flow in the other direction. The large information of gas needle valve is complemented and updated on echemi.com. Control valve & on off valve ,solenoid-valve manufacturer Facebook Twitter Youtube Pinterest Linkedin The disk moves perpendicular to the seat to open or close the flow so the annular space between the disk and seat ring gradually changes. Needle valves, sometimes called plunger valves, enable engineers to control and regulate subtle flow and pressure changes.

Based on their chemical components, they can be used in high-temperature and oxygen operation. 10 GPM.

The needle valve, sometimes known as the gas flow valve, is used to change the flow of gas, and is used to alter the size of the flame. It has a wide range of uses, such as the cutting distance for flame cutting.

4.8.

Although the primary design function is to control flow, on the other hand some valves also provide on-off control. 3 Cavitation-erosion of 84-inch Needle Valve, Alcova Dam, Wyo. Determining which flow control valve type is best for your particular situation depends on a host of criteria, but the most commonly used types include gate valves, globe valves, pinch valves, diaphragm valves, and needle valves. RE: Flow direction in the needle valves. Following the above listed, these functions help you to categorize there types by names. It allows for fine flow adjustment, however it is usually limited to low flow rates. The needle valves stem provides precise control by moving a piston tube open and closed. Avoid extended periods of throttled operation.

Needle valves are similar to a globe valve in design with the biggest difference is the sharp needle-like a disk. 3D Model. In general, there are four methods of controlling flow through a valve. Can be used as a throttle valve as well as an on/off valve. The Spruce / Kevin Norris. However, it can regulate flow through different ways and settings. Inhibitor Drugs. Add fine flow control to tubing lines for oil, butane, diesel fuel, fuel oil, gasoline, kerosene, natural gas, and propane. Results 1 to 4 of 4. Regulation. Isolation Valves: Ball, butterfly, diaphragm, gate, pinch, piston, and plug valves Regulation Valves: Ball, butterfly, diaphragm, globe, needle, pinch, and plug valves Safety Relief Valves: Pressure release and vacuum relief valves Needle Valve Cv Calculations. Needle Valves allow for precise regulation of flow, albeit generally at relatively low flow rates.

Sitemap 13

Different types of valves serve these functions. In 1800, BALTHASAR KREMS of Germany was the first to use a needle with the eye near the point for sewing machine and he had developed it. Single unit Double block and bleed valve. A needle valve is a manual valve used where continuous flow throttling is required for regulation. like a needle valve). It is this part that allows the gas to flow into the barrel. Needle valves have metal to metal seats, but because of the small size, they can be used for positive shut off. #9 Diaphragm Valve. SS 304 Needle valves are used to monitor flow and protect fragile gauges from liquid and gas pressure surges. The more open the valve is, the taller the flame at the top of the barrel. The valves which are mainly used to regulate the flow of fluid in hydraulic circuits are known as flow control valves. Veterinary Raw Materials.

Different types of valves serve these functions. In 1800, BALTHASAR KREMS of Germany was the first to use a needle with the eye near the point for sewing machine and he had developed it. Single unit Double block and bleed valve. A needle valve is a manual valve used where continuous flow throttling is required for regulation. like a needle valve). It is this part that allows the gas to flow into the barrel. Needle valves have metal to metal seats, but because of the small size, they can be used for positive shut off. #9 Diaphragm Valve. SS 304 Needle valves are used to monitor flow and protect fragile gauges from liquid and gas pressure surges. The more open the valve is, the taller the flame at the top of the barrel. The valves which are mainly used to regulate the flow of fluid in hydraulic circuits are known as flow control valves. Veterinary Raw Materials.  The main function of the needle valves is controlling valves and helping engineers and the users of needle valves to properly control and organize water flow and pressure. Image via Flickr by nalundgaard. A Needle Valve is a valve that has a small port and a threaded needle-shaped plunger. 3. specialized purpose. 4.7. Here are 3 tips for you on how to maintain a needle valve. 1.

The main function of the needle valves is controlling valves and helping engineers and the users of needle valves to properly control and organize water flow and pressure. Image via Flickr by nalundgaard. A Needle Valve is a valve that has a small port and a threaded needle-shaped plunger. 3. specialized purpose. 4.7. Here are 3 tips for you on how to maintain a needle valve. 1.  Needle Valves Flow controls and Needle valves are used to reduce the rate of flow in a leg of a system, consequently the restriction slows cylinder speed. The Ashcroft 7001L and 7004L steel needle valves are economical, adjustable throttling devices for severe gauge applications. 4. It functions to control the flow of liquids in delicate gauges, which might be ruined by sudden surges of fluid under pressure. Any process reliant on a controlled flow of air, particularly for the quality of a finished product, will need to utilize a flow control valve with sufficient precision.

Needle Valves Flow controls and Needle valves are used to reduce the rate of flow in a leg of a system, consequently the restriction slows cylinder speed. The Ashcroft 7001L and 7004L steel needle valves are economical, adjustable throttling devices for severe gauge applications. 4. It functions to control the flow of liquids in delicate gauges, which might be ruined by sudden surges of fluid under pressure. Any process reliant on a controlled flow of air, particularly for the quality of a finished product, will need to utilize a flow control valve with sufficient precision.  Food Additives. 5 Reasons to Buy Needle Valves from FAV. uses a tapered pin to gradually open a space for fine control of flow. Is there a way to approximate the loss given the open area and shape. A needle valve has a relatively small orifice with a long, tapered seat, In cart [Remove] 1202026. The damages can be anything like sudden pressure surges of liquids and gases and more. Needle valve is a valve consisting of little port and a strung, needle -molded plunger. Globe valves used to start, stop and regulate flow. For the purpose of discussion in this paper, the terms will be used to express function. Needle Valves are used to make relatively fine adjustments in the amount of fluid flow. Flow control valves are often used to control the speed of pneumatic actuators.

Food Additives. 5 Reasons to Buy Needle Valves from FAV. uses a tapered pin to gradually open a space for fine control of flow. Is there a way to approximate the loss given the open area and shape. A needle valve has a relatively small orifice with a long, tapered seat, In cart [Remove] 1202026. The damages can be anything like sudden pressure surges of liquids and gases and more. Needle valve is a valve consisting of little port and a strung, needle -molded plunger. Globe valves used to start, stop and regulate flow. For the purpose of discussion in this paper, the terms will be used to express function. Needle Valves are used to make relatively fine adjustments in the amount of fluid flow. Flow control valves are often used to control the speed of pneumatic actuators.  The main function of the needle valves is controlling valves and helping engineers and the users of needle valves to properly control and organize water flow and pressure.

The main function of the needle valves is controlling valves and helping engineers and the users of needle valves to properly control and organize water flow and pressure.  Fluid flowing through the valve turns 90 degrees and passes through an orifice that is the seat for a rod with a cone shaped tip. Needle valves, sometimes referred to as plunger valves, are regulating valves and enable engineers to finely control and regulate water flow and pressure. 3. Usually, needle valves are used to control flow and to protect subtle gauges from the damages. Needle Valve Uses. It has good sealing performance. 3. specialized purpose.

Fluid flowing through the valve turns 90 degrees and passes through an orifice that is the seat for a rod with a cone shaped tip. Needle valves, sometimes referred to as plunger valves, are regulating valves and enable engineers to finely control and regulate water flow and pressure. 3. Usually, needle valves are used to control flow and to protect subtle gauges from the damages. Needle Valve Uses. It has good sealing performance. 3. specialized purpose.  These valves always have a directional arrow. 1. We have dedicated section on Carbon Steel Needle Valve in categories. The needle valves are capable to control the pressure and flow. Monoflanges combine the function of up to three valves in a particularly compact body, thanks to a precise network of internal passages and valve chambers. Isolation. Needle Valves are used to make relatively fine adjustments in the amount of fluid flow. They are mainly used to control speed of hydraulic cylinders. I'm looking for literature on the design of needle and seat valves or ball and seat valves, but short of that I'll take a general rule of thumb for flow through an orifice with a centerline obstruction (i.e. #8 Globe Valve. A needle valve is a type of valve which can be used to regulate flow of a substance, usually either gas or water, through an appliance or system. female NPT vent port. Raw Material: Stainless Steel 316, Stainless Steel 304 , Monel, ,Hstelloy,Inconel 625 and 825 ,Incoloy 600,Titatnium Grade 2 ,Super Duplex & other exotic material. These small valves are widely used to accurately regulate the flow of liquids and gases at low flow rates. #10 Ball Valve. The unique feature of the value is the inclusion of a small plunger, with a shape akin to a needle. Common functional designations and their common design types include:. The knob for adjusting flame temperature is needle valve. They have a wide usage for pressure regulation, turbine by-pass, discharge, air regulation, reservoir inlets, and pump start. Neither design has much impact on the actual valve function. Although all valves have the same basic components and function to control flow in some fashion, the method of controlling the flow can vary dramatically. A monoflange includes one, two or three needle valves inside a compact, flange-shaped body, allowing a significant reduction in volume, dimensions, weight and potential leakage points. Anticaking Agent. Ball valves are designed for on-off operation. The valves described so far are small and intended for instrumentation applications. Browse the articles related gas needle valve. Needle valves use a needle-shaped plunger to block the flow path through the valve.Ball valves get their name from their design. Here is a video of a needle valve animation.http://www.mekanizmalar.com/menu-pneumatic.html Multiport Venting gauge valve series. Construction of a needle valve The construction of a typical needle valve includes a tapered pin that gradually opens a space for fine control of flow. OSHA definition of double block and bleed valve, The closure of a line, duct or pipe by closing and locking or tagging two inline valves and by opening and locking or tagging a drain or vent valve in the line between the two closed valves.. Sinpo Valve needle valve function The reason why needle valve function is highly favored in the market can be summarized into two aspects, namely outstanding performance and unique design. 4 Internal Differential Needle Valve 5 Interior Differential Needle Valve 6 Revised Needle Valve tion between gate and valve should be based on function or design form. Needle valves are designed Both valve functions can be accommodated by ball, globe or gate valves. Needle Valve Cv Calculations. Block and bleed valves for process applications are available in sizes up to DN150 or 6 nb. Move a disc, or plug into or against an orifice (for example, globe or needle type valve). Turn the handle to adjust flow in small increments.

These valves always have a directional arrow. 1. We have dedicated section on Carbon Steel Needle Valve in categories. The needle valves are capable to control the pressure and flow. Monoflanges combine the function of up to three valves in a particularly compact body, thanks to a precise network of internal passages and valve chambers. Isolation. Needle Valves are used to make relatively fine adjustments in the amount of fluid flow. They are mainly used to control speed of hydraulic cylinders. I'm looking for literature on the design of needle and seat valves or ball and seat valves, but short of that I'll take a general rule of thumb for flow through an orifice with a centerline obstruction (i.e. #8 Globe Valve. A needle valve is a type of valve which can be used to regulate flow of a substance, usually either gas or water, through an appliance or system. female NPT vent port. Raw Material: Stainless Steel 316, Stainless Steel 304 , Monel, ,Hstelloy,Inconel 625 and 825 ,Incoloy 600,Titatnium Grade 2 ,Super Duplex & other exotic material. These small valves are widely used to accurately regulate the flow of liquids and gases at low flow rates. #10 Ball Valve. The unique feature of the value is the inclusion of a small plunger, with a shape akin to a needle. Common functional designations and their common design types include:. The knob for adjusting flame temperature is needle valve. They have a wide usage for pressure regulation, turbine by-pass, discharge, air regulation, reservoir inlets, and pump start. Neither design has much impact on the actual valve function. Although all valves have the same basic components and function to control flow in some fashion, the method of controlling the flow can vary dramatically. A monoflange includes one, two or three needle valves inside a compact, flange-shaped body, allowing a significant reduction in volume, dimensions, weight and potential leakage points. Anticaking Agent. Ball valves are designed for on-off operation. The valves described so far are small and intended for instrumentation applications. Browse the articles related gas needle valve. Needle valves use a needle-shaped plunger to block the flow path through the valve.Ball valves get their name from their design. Here is a video of a needle valve animation.http://www.mekanizmalar.com/menu-pneumatic.html Multiport Venting gauge valve series. Construction of a needle valve The construction of a typical needle valve includes a tapered pin that gradually opens a space for fine control of flow. OSHA definition of double block and bleed valve, The closure of a line, duct or pipe by closing and locking or tagging two inline valves and by opening and locking or tagging a drain or vent valve in the line between the two closed valves.. Sinpo Valve needle valve function The reason why needle valve function is highly favored in the market can be summarized into two aspects, namely outstanding performance and unique design. 4 Internal Differential Needle Valve 5 Interior Differential Needle Valve 6 Revised Needle Valve tion between gate and valve should be based on function or design form. Needle valves are designed Both valve functions can be accommodated by ball, globe or gate valves. Needle Valve Cv Calculations. Block and bleed valves for process applications are available in sizes up to DN150 or 6 nb. Move a disc, or plug into or against an orifice (for example, globe or needle type valve). Turn the handle to adjust flow in small increments.  Although the basic function is flow restriction, the funda-mental difference between the As a result, a needle valve can help you better regulate the flow rate of fluid in the system. A needle valve is a simple control instrument used in a process system that has the on-off feature and controls fluid flow. to accurately control flow rates of clean gasses or fluids. The needle is long and thin with a gradually increasing diameter towards the stem. Image credit: Eaum M/Shutterstock.com. How to maintain a needle valve? The needle valve obtains its name from the long needle like shape of the disc. Satti. You might also see valves classified by function instead of design. The distinguishing characteristic of a needle valve is the long, tapered, needlelike point on the end of the valve stem. like a needle valve). Optimal for systems with low flow rates and lighter, less viscous content. Globe Valves.

Although the basic function is flow restriction, the funda-mental difference between the As a result, a needle valve can help you better regulate the flow rate of fluid in the system. A needle valve is a simple control instrument used in a process system that has the on-off feature and controls fluid flow. to accurately control flow rates of clean gasses or fluids. The needle is long and thin with a gradually increasing diameter towards the stem. Image credit: Eaum M/Shutterstock.com. How to maintain a needle valve? The needle valve obtains its name from the long needle like shape of the disc. Satti. You might also see valves classified by function instead of design. The distinguishing characteristic of a needle valve is the long, tapered, needlelike point on the end of the valve stem. like a needle valve). Optimal for systems with low flow rates and lighter, less viscous content. Globe Valves.  In this article, Fluid Controls gives you an overview of the function, design and applications of a needle valve, and highlights some of our popular needle valves from Parker. Needle valves are commonly used #6 Pressure Compensated Flow Valve. The valve has an internal seat and is of bar stock construction.

In this article, Fluid Controls gives you an overview of the function, design and applications of a needle valve, and highlights some of our popular needle valves from Parker. Needle valves are commonly used #6 Pressure Compensated Flow Valve. The valve has an internal seat and is of bar stock construction.  Needle valve has multiple functions. The distance between the plunger and the valve seat is controlled by the handwheel in manually operated needle valves. Enzyme.

Needle valve has multiple functions. The distance between the plunger and the valve seat is controlled by the handwheel in manually operated needle valves. Enzyme.  Needle Valve: Definition, Types, Function & Application :- Needle valves , also called plunger valve sometime, are the pressure and flow regulating valves which helps to accurately control the pressure and.

Needle Valve: Definition, Types, Function & Application :- Needle valves , also called plunger valve sometime, are the pressure and flow regulating valves which helps to accurately control the pressure and.  Available in multiple lengths, see order code, options. Needle Valves are used to meter fluid flow through tubing or ports.

Available in multiple lengths, see order code, options. Needle Valves are used to meter fluid flow through tubing or ports.  Needle valves are linear motion valves, these valves are used in instrument systems for throttling of small volumes. Sorted Product Name +/-. Standard Valve Gate. They provide the most practical means for varying the orifice to determine the exact orifice size for any specific service condition.

Needle valves are linear motion valves, these valves are used in instrument systems for throttling of small volumes. Sorted Product Name +/-. Standard Valve Gate. They provide the most practical means for varying the orifice to determine the exact orifice size for any specific service condition.  These valves also contain a check-valve that bypasses the needle so that there is restricted flow in one direction and unrestricted flow in the other direction. The large information of gas needle valve is complemented and updated on echemi.com. Control valve & on off valve ,solenoid-valve manufacturer Facebook Twitter Youtube Pinterest Linkedin The disk moves perpendicular to the seat to open or close the flow so the annular space between the disk and seat ring gradually changes. Needle valves, sometimes called plunger valves, enable engineers to control and regulate subtle flow and pressure changes.

These valves also contain a check-valve that bypasses the needle so that there is restricted flow in one direction and unrestricted flow in the other direction. The large information of gas needle valve is complemented and updated on echemi.com. Control valve & on off valve ,solenoid-valve manufacturer Facebook Twitter Youtube Pinterest Linkedin The disk moves perpendicular to the seat to open or close the flow so the annular space between the disk and seat ring gradually changes. Needle valves, sometimes called plunger valves, enable engineers to control and regulate subtle flow and pressure changes.  The needle valve, sometimes known as the gas flow valve, is used to change the flow of gas, and is used to alter the size of the flame. It has a wide range of uses, such as the cutting distance for flame cutting.

The needle valve, sometimes known as the gas flow valve, is used to change the flow of gas, and is used to alter the size of the flame. It has a wide range of uses, such as the cutting distance for flame cutting.  4.8.

4.8.  Although the primary design function is to control flow, on the other hand some valves also provide on-off control. 3 Cavitation-erosion of 84-inch Needle Valve, Alcova Dam, Wyo. Determining which flow control valve type is best for your particular situation depends on a host of criteria, but the most commonly used types include gate valves, globe valves, pinch valves, diaphragm valves, and needle valves. RE: Flow direction in the needle valves. Following the above listed, these functions help you to categorize there types by names. It allows for fine flow adjustment, however it is usually limited to low flow rates. The needle valves stem provides precise control by moving a piston tube open and closed. Avoid extended periods of throttled operation.

Although the primary design function is to control flow, on the other hand some valves also provide on-off control. 3 Cavitation-erosion of 84-inch Needle Valve, Alcova Dam, Wyo. Determining which flow control valve type is best for your particular situation depends on a host of criteria, but the most commonly used types include gate valves, globe valves, pinch valves, diaphragm valves, and needle valves. RE: Flow direction in the needle valves. Following the above listed, these functions help you to categorize there types by names. It allows for fine flow adjustment, however it is usually limited to low flow rates. The needle valves stem provides precise control by moving a piston tube open and closed. Avoid extended periods of throttled operation.

Needle valves are similar to a globe valve in design with the biggest difference is the sharp needle-like a disk. 3D Model. In general, there are four methods of controlling flow through a valve. Can be used as a throttle valve as well as an on/off valve. The Spruce / Kevin Norris. However, it can regulate flow through different ways and settings. Inhibitor Drugs. Add fine flow control to tubing lines for oil, butane, diesel fuel, fuel oil, gasoline, kerosene, natural gas, and propane. Results 1 to 4 of 4. Regulation. Isolation Valves: Ball, butterfly, diaphragm, gate, pinch, piston, and plug valves Regulation Valves: Ball, butterfly, diaphragm, globe, needle, pinch, and plug valves Safety Relief Valves: Pressure release and vacuum relief valves Needle Valve Cv Calculations. Needle Valves allow for precise regulation of flow, albeit generally at relatively low flow rates.

Needle valves are similar to a globe valve in design with the biggest difference is the sharp needle-like a disk. 3D Model. In general, there are four methods of controlling flow through a valve. Can be used as a throttle valve as well as an on/off valve. The Spruce / Kevin Norris. However, it can regulate flow through different ways and settings. Inhibitor Drugs. Add fine flow control to tubing lines for oil, butane, diesel fuel, fuel oil, gasoline, kerosene, natural gas, and propane. Results 1 to 4 of 4. Regulation. Isolation Valves: Ball, butterfly, diaphragm, gate, pinch, piston, and plug valves Regulation Valves: Ball, butterfly, diaphragm, globe, needle, pinch, and plug valves Safety Relief Valves: Pressure release and vacuum relief valves Needle Valve Cv Calculations. Needle Valves allow for precise regulation of flow, albeit generally at relatively low flow rates.