The first step is to get your card printed onto a transparency sheet. We offer these general printing tips and frequently ask questions to highlight key areas. 24 pt+ and wet strength for beverage containers.

The first step is to get your card printed onto a transparency sheet. We offer these general printing tips and frequently ask questions to highlight key areas. 24 pt+ and wet strength for beverage containers. Inks formulated with higher solids are recommended so ink film integrity, adhesion, and abrasion characteristics are achieved. 2.5 Ink Holdout - Due to the non-absorbent substrate, ink holdout is maximized. 42 lbs./ream (68 gsm) -- Beverage and general purpose label applications. Vacumet Corp. has an extensive technical team capable of supporting any converting operation. The holographic effects are created by metalizing the surface with a thin layer of shiny silver aluminum. Please see our Printers FAQ section for more information. Unit 3, Stratton View Business ParkBude, Cornwall, EX23 9NR, United Kingdom, After Hours Creative Ltd 2022Company No: 6857235. In each instance, the unique look of the cardstock can help you stand out. a.

Entirely optional, but if you have them laying around, I highly recommend busting them out. Eventually, I had my image printing at a quality I was happy with by using HPs photo settings.

The graphic design determines number of ink layers and opacity.

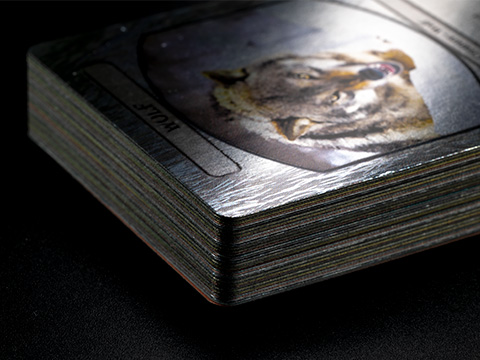

The graphic design determines number of ink layers and opacity. 3 Stunning Applications for Glitter Cardstock, How Specialty Paper Can Help Your Business. Once youve figured out whether or not youre going to attach your layers, all thats left is to cut them out and get them in a sleeve. Can I have my design printed on holographic rainbow card stock. When printing directly on the metallic surface without an opaque white base coat, there are no special precautions necessary for a superior printed finish. Whether you're creating a birthday card, a thank-you card, or just a fun card to say hello, holographic cardstock can add an extra touch of personality. During printing, material temperatures exceeding 104F can diminish the holographic appearance. Amazon didnt have it in stock, so I had to hop in the car for this one. I spent a lot of my formative gaming years playing Magic, so Ive got a pretty solid appreciation for holographic cards. Were experts at eye-catching, working with metallic foil stamping and sparkling Pantone metallic inks to bring shine and depth to projects like black business cards (one of our specialties) and sleek white wedding invitations. These holographic cards are thicc. Grain direction is noted for sheets with an underline on the grain dimension. There are a few things to keep in mind when printing on this type of paper. You can print these sheets on the end of another project.

For "first-time" printers, we recommend process testing some sheets prior to printing a large project. If necessary, fan or air the stock before feeding onto the press. Consider using holographic cardstock if you're throwing a party and want your invitations to stand out. c. The use of mineral oil, paste and gel reducer should be avoided. Posted in. Aqueous coatings need to be specifically designed for use on metallized or foil papers so the ink film is allowed to set prior to final dry of the coating. Check your inbox to confirm your subscription.

We do the highest-quality holographic foil work in the industry (something to brag about!). With our expertise and savvy, well lead you to the best white-ink style for your projectfrom white foil stamping to Pantone white ink offset to white letterpress. For best performance, remove the film wrapping and allow the material to adjust to the press room temperature conditions at least twenty-four (24) hours before printing. With a quick spray of adhesive, I attached the cardstock and the transparency sheet. For example, to achieve a shiny, glossy shade, transparent inks should be used. NovaVision does not warranty any information provided here as to its correctness. Holographic paper and board stock have two dimensional holographic effects that reflect and diffract interior and natural lighting. Special thanks to Amerikano of the MCM Podcast for sending me down this rabbit hole. SOME ONLINE PRICING IS TEMPORARILY SUSPENDED. This attention-grabbing rainbow printing technique creates a futuristic effect on invitations, business cards, and stationery and even on the edges of books and packaging. For a solid appearance, opaque inks are recommended. Additives may be used in the damping solutions to aid the drying process. Metalized paper labels will perform on most standard gluing equipment. Sign up for the Publicides rare but exciting updates! A range of 65F (18C) to 75F (24C) and 40% - 60% relative humidity is recommended for the press room while running and/or stacking holographic paper and board. When your project calls for a transparent finish, whether thats high-gloss, matte, metallic, holographic, or even pastel, we know exactly where to turn. Using de-curling units can guard against curl sometimes caused during the printing process. Tack: 14 or less. NovaVision stocks direct metalized material and material which is laminated with holographic film.

I wanted to go a little bit further and see if I could attach the two. The first color should be between 18 to 20 at 1,200 rpm or 11 to 14 at 800 rpm. Avoid excessive heat (maximum 104F) which may accumulate in printed stacks. "Make-ready" can be done with more economical coated papers. For unbeatable dazzle, we print on mirror reflective metallic paper, too. These transparency sheets have two distinct sides, and only one of them is meant to hold ink. # Type at least 3 character to search # Hit enter to search, Looking for a stationery set? I used inkjet sheets, but just be aware of what type of printer youve got. This information should always be used along with recommendations of the ink supplier and press manufacturer. 6. Contact your ink supplier in advance and ask for recommendations. All additives should be used according to the manufacturer's recommendation. When printing on COATED backsides, metallic surfaces or film, inks dry by oxidation. A holographic paper is simply a coated paper, and the coating reacts with laser light to create the holographic effect. Temperatures exceeding 104F during printing or while in storage can diminish the holographic effect. Ask me how I know this. By improving shelf appeal, holographic paper and board has proven its success to increase sales through improved product awareness and enhanced brand image. This embossed surface diffracts the light into many colors and reflects the light. All Rights Reserved.

Are holographic substrates environmentally friendly? Holographic Foil Cardstock sold by Michaels, Zombicide Player Storage Making the Most of Small Spaces. White can be printed underneath full colour to allow for full colour designs on rainbow card. Sheet damping must be even across the sheet especially avoiding excess water at the edge of the sheets. This team has experience in all commercial print technologies, laminating, holography, coating and general converting. The minimum amount of ink and water needs to be applied.

Designing with a variation of opaque white intensities, opaque color inks and translucent color inks will create unique and eye-catching effects. 2020 Announcement Converters. For direct metalized products, the metalized holographic surface provides improved gloss, enhanced appearance and a silver reflective background. As an Amazon Associate I earn from qualifying purchases. Your clients and customers will be impressed with your attention to detail, and you'll be sure to make a lasting impression. It can add a touch of excitement to any project. HOLOPRISM is a registered trademark of Vacumet.

A range of 65F to 75F and 40% to 60% relative humidity is recommended for the press room while running and/or stacking. When printing on UNCOATED both sides, inks dry by absorption. For this step, I used the exact product pointed out in the video, which is Holographic Foil Cardstock sold by Michaels. or check out our range of holographic business cards. Announcement Converters offers a wide selection of holographic cardstock paper, so you're sure to find the perfect paper for your needs. Delivering maximum contrast, this technique wows on black paperthink black business cards and black invitationsbut it also pops on other paper colors, dark to light. Our stock holographic paper and board stock is silver due to the metallization process. However, holographic material offers a better value with the proven increase in product sales and enhanced appearance.

In multi-station presses, the first station ink should have tack of 14. Tests should be conducted to determine the drying time and temperature necessary to give acceptable line speeds without diminishing the holographic effects. A 45-micron particle size, using cornstarch and tapioca powder is suggested. To reduce offsetting of inks, use small amounts of drying powders. Because the challenge of balancing ink and water is removed, waterless printing provides a brighter, more stable four-color reproduction with higher image resolution. Yes, metalized paper is produced using only one to three ounces of aluminum per ream, making our paper re-pulpable and capable of being de-inked.

Inks must be made from fully dried materials. It does not affect the physical properties (tear, tensile, burst strength, stiffness, etc) of the sheet. Using both ink types can create a vivid, three-dimensional appearance. Processes with low print take-off may require the addition of up to 12% isopropanol to reduce the surface tension and minimize the amount of water delivered to the paper surface. Lubricating the die blade with a wax-impregnated separator will keep the blade sharp and prolong its life. It gives the art a sort of speckled finish if you look at it closely. As a test, I cut out one of my cards and one card-sized piece of holographic foil. These pretty much matched my expectations, but definitely reminded me why I hate printers. Thank you to all our Patreon supporters who help making this content possible, especially: If youd like to support the site, you can use the Amazon affiliate links below. The air velocity should be adjusted for proper floatation to prevent the sheet from rippling or creasing. Either aqueous or UV-cured over-coatings are recommended. A single-sided card might not feel too different though. NovaVision communicates these tips as suggestions and guidelines and assumes no liability for any loss or damage resulting from any acts or omissions based on this information provided. For starters, holographic paper can be very thick.

Click the links in the table of contents below to take you to that section of the page: A. Using special blanket hardener at start-up will prevent sticking and reduce picking. One growing trend in the world of printing is holographic paper. Design Frequently Asked Questions and Tips. 2.7 Blankets - Printing blankets should be conventional, designed for quick release. Funds from these links go towards supporting this site. A move for the extra-bold: layering in neon paper. Flexographic and gravure ink systems should be recommended by the ink manufacturer. The holographic surface may reflect rough handling in the form of bruises or dull scuff marks. The journey was long and fraught with peril, but in the end, Im happy with the outcome. Holographic cardstock paper may be the perfect solution. Fount solutions should not be too acidic (ph 5.5) and should be used sparingly as excess use will inhibit the drying process. Remember, your base color is silver reflective. If you agree to use cookie files, click 'Allow Cookies,' otherwise, click Cookie Settings to allow or prohibit some cookie categories.

For all coating recommendations, please consult your coating and ink supplier. So if you're looking for a way to add a little extra personality to your next project, considerprinting on holographic cardstock paper. Our stock products are available in small carton quantities of 100 sheets. The final overprint coating should be selected for clarity to minimize any impact on the holographic brightness. ph range: 4-5. When handling, take care not to use excessive clamping pressure and not to push rolls or cartons over uneven or dirty floors. Excessive heat may cause matting or diminish the holographic effect. Id probably only stick with double-sided cards that arent shuffled in anywhere. You must have JavaScript enabled in your browser to utilize the functionality of this website. Is designing on a holographic background/substrate complicated? Although conventional inks work well, UV-cured inks are ideal. I used a paper cutter to make sure I got a nice straight edge. Consider using holographic cardstock if you have a business where you don't need the most white-collar-looking business cards.

Here are three purposes that holographic cardstock can fulfill for you. 2.3 Fountain Solution - Fountain solution must be mixed fresh and carefully maintained due to the non-absorbent nature of the metalized surface. It was a great starting point, but I wanted to talk a bit about my experience with the process, and where it can go wrong. I also had some corner punches already, so I rounded my corners to make them feel more like a finished product. Thank you! Printers should consult with their ink supplier and press manufacturer for final printing recommendations.

They carry several foil cardstock products, so make sure you get the one that says holographic foil in the subtitle.

Grain direction is less significant for thicker material. This type of paper has a shimmery, iridescent finish that can add a touch of fun and excitement to any project.

Diffracts light to create an eye-catching effect, Variety of patterns for more design flexibility, Integrate with printed graphics for a dynamic effect, Attractive packaging enhances the product image and brand, "Eye-catching" packaging creates more shelf appeal, Differentiates product for higher market share. We can even edge business cards and coasters with the futuristic hues. Holographic cardstock paper is a growing trend in the world of paper, and it's easy to see why. 4. This information contains basic guidelines for printing and using holographic material. f. Low ink coat weights are recommended to facilitate the drying process, Generally, no additional special procedures are required for flexo printing. If you don't have a laser printer, you may be able to find a local print shop that can print your holographic cardstock for you. Do not double stack skids. Why Colored Paper Helps Your Business Stand Out. Fountain solution: 15 % minimum recommended alcohol content, 25% maximum. For best results, test adhesion of ink systems. If you're not sure whether your printer can handle coated paper, you can check the printer's manual or contact the manufacturer directly. Holographic papers and boards can be "tailed" onto a white paper/board run to create product samples. So, make your own decisions here, and probably test on a single card before you commit. Wet-trapping: Ink can be wet trapped on metalized paper for multiple color printing. b. Viscosity can generally be used as supplied by the ink manufacturer and adjustments should be made according to the manufacturer's recommendations. Wouldnt want a fingerprint smooshed between the two layers, right? Order a Sample Pack to see for yourself! Material is wrapped with film to protect against moisture gain or loss. A final clear coating on the holographic side is recommended to cap printed materials and prevent offsetting. 3 Ways You Can Better Your Wedding Invitations, Family Business Success Through Simplicity, Why Nude Is the Right Neutral Choice for Your Envelopes. For example, 28 inch x 40 inch sheets are noted as 28x40; the underline indicates that the grain direction is the 40 inch dimension. Or, you can vary the ink transparency by changing the intensities of the underlying opaque white inks (10% to 50% screen) to create a more subtle holographic effect in some areas -- while leaving other areas 100% unprinted for the maximum holographic effect. Blanket: Conventional low tack; quick release type. Stretch-wrap the holographic paper/board between printing and converting processes to minimize moisture variations, which will minimize curling. Announcement Converters was founded in 1972 in Hialeah, Florida as a division of American Business Card, a large trade themographer located in New York City which began operating in 1924.

Glue with a pH of 9 or lower. e. Additional driers in the ink are recommended where tolerable to ensure hard drying. 50 lbs./ream (82 gsm) -- Beverage and general purpose label applications. Registered in England. Formulations are readily available which are specifically designed for metalized papers or laminated film. Your guests will be sure to remember your event when they receive their invitations in the mail. VAT No: 977780649. To reduce stacking pressure, use lifts of up to 2,000 sheets. Large amounts of DOP plasticizer in gravure inks may interfere with proper ink adhesion. Butcan you print on holographic cardstock paper? If I were at a table playing the game, I wouldnt even notice.

Dryography may also enhance color trapping and reduce problems with process color dominance, such as flesh tones that appear too yellow or red in cast. Having perfected the best way to achieve a saturated, opaque effect, we often use a combination of offset and letterpress printing for maximum awesomeness. For film laminated products, the film also enhances the physical properties of the sheet. Kraft paper hang tags with blaze orange, signal green, rocket red, or horizon blue printing, perhaps? On multi-station presses, the first station should have a tack of 14 with each successive station delivering inks with successively lower tack levels. 5. The viscosity can generally be used as supplied by the manufacturer and adjustments should be made according to the manufacturers recommendations. For laminated paper and board stock, the grain direction is irrelevant, since the film lamination provides added strength in all directions. Inks must be made from fully oxidizable materials. By using opaque white inks, you can block out any design area you choose so the holographic background will not show through. Finally, you'll want to use a high-quality printing setting.

What Are the Many Uses of Glitter Card Stock? This is for all inks including opaque white. Holographic FoilWhite InkClear FoilNeon & Fluorescent PrintingMetallic Ink. 70 lbs./ream (114 gsm) -- General purpose label applications, decorative bags, magazine covers and advertisements.

It may not run through your printer as smoothly as standard printer paper. 80 lbs./ream (130 gsm) -- Posters, magazine covers and advertisements. 100# text -- book cover, DVD inserts, magazine covers, sports programs, 10 pt (230 gsm) and 12 pt (275 gsm) -- Point-of-purchase displays, tobacco packaging, blister cards, greeting cards, trading cards, 14 pt (300 gsm) - blister cards, fine trading cards, very light packaging boards (small cosmetics, etc), 16 pt (350 gsm)-18 pt (375 gsm) - Ocards, packaging (moderate size), golf ball boxes, 22 - 24 pt - large folding cartons (cereal, electronics, etc).

- Iles Formula Hair Mask

- Object Detection App For Blind

- React Native Horizontal Slider

- Target Projection Alarm Clock

- Gold Stacking Rings Wedding Band

- Murano Luggage Storage

- Best Markers For Black Dry Erase Board

- How To Prepare Male Fertility Tea