Another issue with valve exhaust port flow controls is if the airline from the cylinder to the valve is long, it is possible that the cylinder will have already completed its stroke before the exhaust cylinder flow control will have had time to throttle the exhaust flow of air and slow the cylinder. The ideal installation path is that the air flowing out of the air cylinder is throttled. There are various types of valves available, some offering open/close capabilites to enable the user to allow or block the flow. if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[580,400],'about_air_compressors_com-medrectangle-4','ezslot_5',119,'0','0'])};if(typeof __ez_fad_position!='undefined'){__ez_fad_position('div-gpt-ad-about_air_compressors_com-medrectangle-4-0')}; Flow is directly proportional to speed and pressure is directly proportional to strength.

Another issue with valve exhaust port flow controls is if the airline from the cylinder to the valve is long, it is possible that the cylinder will have already completed its stroke before the exhaust cylinder flow control will have had time to throttle the exhaust flow of air and slow the cylinder. The ideal installation path is that the air flowing out of the air cylinder is throttled. There are various types of valves available, some offering open/close capabilites to enable the user to allow or block the flow. if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[580,400],'about_air_compressors_com-medrectangle-4','ezslot_5',119,'0','0'])};if(typeof __ez_fad_position!='undefined'){__ez_fad_position('div-gpt-ad-about_air_compressors_com-medrectangle-4-0')}; Flow is directly proportional to speed and pressure is directly proportional to strength.  Requires both speed controls to be adjusted to the same setting. Essentially, the flow will change the speed of an actuator while the pressure will change the force of the actuator.

Requires both speed controls to be adjusted to the same setting. Essentially, the flow will change the speed of an actuator while the pressure will change the force of the actuator.  Without the use of linear motion potentiometers, ensuring accuracy and dependability is a huge challenge. The flow control valve and needle valves are used to decrease the actual flow rate in a particular section of a pneumatic circuit.

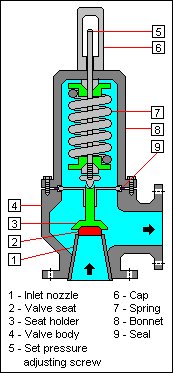

Without the use of linear motion potentiometers, ensuring accuracy and dependability is a huge challenge. The flow control valve and needle valves are used to decrease the actual flow rate in a particular section of a pneumatic circuit.  The plug or set screw is then installed into a component port below the conductor fitting. The actuator speed is limited by restricting the air flow as it exits the component. Ball valves are very reliable and durable, even after very lengthy usage. b. In some cases, such issues could mean youre operating an unsafe system that could malfunction at any time. In the diagram, you can see the compressed air bypass.

Fig. The adjustable component resembles a needle, which can be screwed into place to block the actuator. A pressure regulator is responsible for preventing pressure fluctuation by controlling pressure as it is coursed through an actuator or another part of a pneumatic system. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); More Exhibitors Drop Out of CONEXPO-CON/AGG and IFPE Shows. Terms and Conditions, When engineered and combined with pneumatic flow control valves, they ensure the reliable operation of pneumatic systems over a long life and a high return on investment for manufacturers. 1-22: Needle Valves Restrict Flow in Both Directions. 1-21.

The plug or set screw is then installed into a component port below the conductor fitting. The actuator speed is limited by restricting the air flow as it exits the component. Ball valves are very reliable and durable, even after very lengthy usage. b. In some cases, such issues could mean youre operating an unsafe system that could malfunction at any time. In the diagram, you can see the compressed air bypass.

Fig. The adjustable component resembles a needle, which can be screwed into place to block the actuator. A pressure regulator is responsible for preventing pressure fluctuation by controlling pressure as it is coursed through an actuator or another part of a pneumatic system. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); More Exhibitors Drop Out of CONEXPO-CON/AGG and IFPE Shows. Terms and Conditions, When engineered and combined with pneumatic flow control valves, they ensure the reliable operation of pneumatic systems over a long life and a high return on investment for manufacturers. 1-22: Needle Valves Restrict Flow in Both Directions. 1-21. Pressure regulators work with sensors to monitor the pressure as it expands as it moves through a pneumatic system. Flow Control Valves in Pneumatic Control Systems. Or are you in need of parts for your system? There are different types of pneumatic flow control valves, each with different functionalities in a pneumatic line. In an internal bleeding system, a venting regulator simply re-routes the additional pressure. Save my name, email, and website in this browser for the next time I comment. Requires a reverse flow check valve only for the cap end of the cylinder. A flow control valves main purpose in pneumatic systems is to regulate the pressure or flow of air. The design intent is to insure that the adjustment is not tampered with or removed. With restricted compressed air inrush due to the needle valve throttling the in-flowing air, pressure can sometimes build up in the cylinder to the point that the piston moves. While this could cause huge losses for manufacturers that rely on pneumatic systems for mixing and measuring purposes, the truth is, many pneumatic lines arent maintained properly. Fig. 6mm 2pcs As a result of the pressure valves opening and closing in response to pressure levels, pressure is kept at a relatively constant level as it reaches the actuator or other pneumatic device. However, this kind of venting system is not suggested for use with large-flow systems because large volumes of air cannot be released through a venting-type regulator. linear motion conductive plastic potentiometers andhall effect potentiometers that are built to last. Contact us at (07 3344 4711) now.

The meter-out flow control can al. Globe valves have a stationary ring seat and a disk-type element referred to as a plug. If the flow control fitting is installed on the exhaust ports of the directional control valve, a reverse flow check valve is not required, but may be used because it is often included as an integral part of the flow control fitting. Inindus In order to get the cylinder speed slowed to your desired cycle rate by throttling the exhaust with a needle valve since compressed air has to follow that same path when the cylinder reverses, you now have throttled the inrush of compressed air into the cylinder too. Connect and transact with thousands of top North American companies today fitting flow control od pneumatic push valve speed tube inch piece air

Select From Over 500,000 Industrial Suppliers. The flow control, depending on the type, might be similar in appearance to a needle valve but it does not work the same way. However, the load may jump if the actuator or piping has a large volume of de-pressurized air that will compress before being forced out the restriction. Prices pulled from the Amazon Product Advertising API on: Product prices and availability are accurate as of the date/time indicated and are subject to change. also known as a speed controller are equipment specially designed for use in pneumatic and hydraulic systems. Contact us at (07 3344 4711) now. valve pneumatic control flow ec21 While a needle valve regulates the flow in two directions, the flow control valve, however, secures control in one direction. When the valve controlling the cylinder shifts, the airflow to the air cylinder reverses, and now the air is flowing into the cylinder through what was just the exhaust line. document.getElementById("copyright_year").innerHTML = new Date().getFullYear(); If you have any questions regarding pneumatic flow control valves, please leave a comment below, with a photo if applicable, so that someone can help you! When the air pressure travels in the opposite direction through a path of increased resistance, it will get proportionally controlled by the flow control valve. if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[580,400],'about_air_compressors_com-medrectangle-3','ezslot_1',118,'0','0'])};if(typeof __ez_fad_position!='undefined'){__ez_fad_position('div-gpt-ad-about_air_compressors_com-medrectangle-3-0')}; They are designed so that air flows in one direction, which allows free flow in the opposite direction. Its important to not confuse flow control valves with pressure controllers, or regulators. Or are you in need of parts for your system? , Joysticks are an essential control component for many types of machines and equipment. Safety tip: Caution should be used when applying meter-out flow controls as load induced pressures could cause the rod end pressure to become intensified and this pressure could exceed the maximum pressure rating of the cylinder. Pressure and venting-type valves both help control pressure, whereas needle valves help control the flow within a pneumatic pressure system. Flow control valves work by requiring a pressure differential between upstream and downstream pressure. There are two ways the excess pressure can be released: an internal bleeding system or an external bleeding system. Privacy Statement and pneumatics All Rights Reserved. Cylinder flow controls come in all shapes and sizes. The exhausting compressed air tries to flow to the patch of least resistance, tries to bypass the throttle in the flow control, cannot as the ball is seated on the check by that moving air, and the cylinder piston speed is controlled in the reverse direction as well. As the valve is progressively opened, more and more air is allowed to flow through the valve, until when the valve is fully opened and the flow is at its maximum. If your current flow controls are allowing air to leak out of the pneumatic system or experiencing other problems, then your system cant operate at full potential. Others are built to screw right into the cylinder port. 1-22). The simplest flow control is a fixed, non-adjustable orifice. Since only the exhausting compressed air is throttling with the flow control, the inrush of air in the other airline flows at full volume. Once the pressure has reached the maximum level of expansion, a sensor is triggered by the high pressure, which in turn signals to the air pressure valve to close thus cutting off pressure. The direction of free flow should be indicated on the body of the fitting. valve directional control pneumatic A pneumatic flow control valve circulates air throughout a larger pneumatic system by either allowing or inhibiting the flow of pressurized air, whose force is then used to power a device. With advanced flow control capabilities, these potentiometers ensure stable control of the valve in critical areas near closing positions. valve control pneumatic diaphragm FIP Connections, Brass, Breezliy 2 Pieces Heavy Duty Brass Instrument Replacement Control Needle Valve 1/4" Npt Female X 1/4 Npt Female Connection, Needle Valve vs Ball Valve Differences, Design, Mechanisms, Applications & More, Globe Valve vs Ball Valve Differences, Design, Mechanisms, Applications & More, Globe Valve vs Gate Valve Differences, Design, Mechanisms, Applications & More, Butterfly Valve vs Gate Valve Differences, Design, Mechanisms, Applications & More, Types of Compressed Air Valves Guide To Pneumatic Valves, Air Compressor Air Line Non-Return valves/Inline (In The Air Line) Air Check Valves Explained, Air Compressor Troubleshooting Check Valve, Unloader Valves On Twin V Piston Compressor Guide. The flow control valve also known as a speed controller are equipment specially designed for use in pneumatic and hydraulic systems. Meter-in Valve also known as the reverse flow control valve, this type, on the other hand, limits the flow to the actuator. Your email address will not be published. Globe valves are designed to regulate the flow of air in a pipeline. pressure compensated schematic flow control hydraulic valves valve diagram orifice troubleshooting Here, we'll to look at why engineering pneumatic flow control valves withlinear motion potentiometers is vital. Thomas Register and Though there are different types of flow control valves available, they all work on the same basic principle. Often found in basic on-off applications, and variable flow systems that have temperature, flow, and pressure changes, two-way control valves have inlet and outlet ports that help save energy and money by reducing absorbed pumping power, and running heating and cooling systems under variable speeds. valve control pneumatic flow valves cylinder symbol pneumatics nitra faq speed hydraulic cylinders

There will typically be a schematic on the side of the flow control to show the correct plumbing orientation. They consume very little power and have proved themselves valuable and accurate in high-end flow control applications. Easy handling and installation also ensure quick connection to the pneumatic flow control valves with external signaling and visualization options that save time and effort. But then, as it does, the resulting larger volume inside the cylinder momentarily lowers the air pressure behind the piston. Although these two systems may function similarly, they are used for different purposes. bleed control pneumatic valve controller zero installed pico pneumatically booster filter head industrial mounting 1-23) are adjustable orifices with an integral check valve to permit flow (speed) control in one direc-tion only and reverse flow with minimal restriction. In order to restrict or slow down flow, the valve features an adjustable component positioned so as to prevent an actuator, or other device, from releasing more air than the system can handle at a given time, thus helping maintain a constant flow rate. The responsibility of a flow control valve is to control the flow in a single direction. These types of valves utilize a wedge-like disc which helps to isolate the flow of the medium and can provide a very tight seal! . 2. 1. Sizing An Air Compressor, Sizing An Air Compressor For Impact Wrench, Sizing An Air Compressor For Spray Painting, Sizing An Air Compressor For Double Acting Air Sander, Sizing An Air Compressor For An Air Stapler, Sizing An Air Compressor For Sandblasting, Spray Texture Gun Air Pressure Requirements, Sizing An Air Compressor For Car Detailing, Air Compressor Troubleshooting, Solutions & Common Problems, Air Compressor Repair DIY & Repair Centers, Why An Air Compressor Wont Build Pressure, Air Compressor Keeps Tripping Circuit Breaker Solved, Air Compressor Reset Button Keeps Tripping? Aside from the commonly used directional control valves, there are valves that are designed to serve more specific purposes, such as pressure regulator, venting-type regulator valves, and needle valves. The control capabilities that linear motion potentiometers provide can be customized to the needs of your system. Uni-directional vales will often have a check valve device allowing full airflow in the opposite direction to ensure directional control. A bypass check valve will also be integrated in the fitting to permit free reverse flow. For more detailed information, and comparisons on the types of flow control valves, please visit the following articles: I recommend that you do not purchase a needle valve to try and provide speed control for an air cylinder. Needle control valves are variable control valves that are not compensated by pressure. c. Requires a reverse flow check valve only for the rod end of the cylinder. if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[468,60],'about_air_compressors_com-box-3','ezslot_2',117,'0','0'])};if(typeof __ez_fad_position!='undefined'){__ez_fad_position('div-gpt-ad-about_air_compressors_com-box-3-0')}; Traditional flow valves have an aperture that is designed to change, which allows the flow rate to be increased or decreased. The air, therefore, doesnt directly exhaust and instead travels through the valve at an increased resistance before being expelled slowly. Some come with their own quick fittings already installed.if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[336,280],'about_air_compressors_com-box-4','ezslot_6',120,'0','0'])};if(typeof __ez_fad_position!='undefined'){__ez_fad_position('div-gpt-ad-about_air_compressors_com-box-4-0')}; Other cylinder flow controls screw into the exhaust ports of the air valve instead of the air cylinder ports.

valves controls tactair Thomasnet Is A Registered Trademark Of Thomas Publishing

Manufacturers specializing in mixing and measuring processes rely on precision to ensure accurate flow control of fluids in a pneumatic system. Gate valves are linear motion valves that are best suited to shutoff applications, especially emergencies as theyre so quick and easy to close. Control valves often have a finely machined stem that matches the profile of the valves seat. Companies like P3 America provide a wide range of durable precision linear potentiometers, such as Now the inrushing compressed air tries to bypass the restriction, succeeds in blowing the check ball off its seat, and the air now has a free and open path to pressurize the cylinder providing relatively instant, full force, cylinder rod movement. Having the right components to ensure smooth system operation is critical. By adjusting the depth of the needle, you can change the flow rate of the medium coming through the valve by controlling the size of the orifice, allowing more or less flow through the valve. Reviews on performax 26 gallon air compressor? Compressed Air Information. The control valves here essentially control and reduce the amount of exhaust that is being expelled. The result is that the cylinder piston will move very quickly from the stopped location as a full flow of compressed air enters the cylinder. A pneumatic flow control valve is designed to regulate the pressure or flow of air. Save my name, email, and website in this browser for the next time I comment. All rights reserved. Needle valves are used to help control flow by restricting the amount of air the allow through. Designing an Not only do they provide stock quality parts, but they also offer an excellent sourcing facility for those hard-to-find parts. California Air Tools Compressors Information, Servicing & Manuals, Compressor brand identification so I can rebuild, How to Use an Air Compressor Guide to Operating Air Compressors, Air Compressor Overheating: 9 Most Common Reasons & How to Prevent It, UST Power System Plus Air Compressor Wont Reach Cut-Out Pressure, Emglo Air Compressor Wont Reach Cut-Out Pressure, Makita Air Compressor Wont Reach Cut-Out Pressure, Air Compressor Wont Reach Cut-Out Pressure Troubleshooting, Sanborn Air Compressors Information, Manuals, Service Locations, Top Air Compressor Manufacturers & Air Compressor Brands List, Plumbing an Air Compressor Setup Running Air Compressor Lines In A Garage, How To Calculate CFM of Air Compressors PSI to CFM Conversion, Identifying An Older Air Compressor Serial Numbers, Photos & Antique Air Compressor Identification, Air Compressor Troubleshooting, Solutions, Common Problems & Causes, How To Choose An Air Compressor Buying Air Compressors 2021, Compressed Air Treatment Guide Compressed Air Preperation And Treatment, What is Compressed Air? valve co2 flow control system diy tube 30pcs throttle pneumatic hose sa speed air water diffuser planted aquarium needle tank Amazon and the Amazon logo are trademarks of Amazon.com, Inc or its affiliates. Ill dive into the types further down the page! Flow controls commonly used in pneumatic systems are meter-out. By using this site, you agree to our, A type of pneumatic pressure valve in an industrial plant, Connect and transact with thousands of top North American companies today, Top Valve Manufacturers and Suppliers in the USA, Top Manufacturers and Suppliers of Butterfly Valves, All About Aerosol Valves - How they Work, Specifications and Selection Criteria, All About Pinch Valves - Design, Applications and Considerations, All About Piston Valves - Design, Applications and Considerations, All About Poppet Valves - Applications, Design and Considerations, Types of Cement used in Construction and Civil Engineering, All About Rotary Lobe Pumps - Types, Uses and How they Work, The Best Commercial Margarita Machine, According to 2,000+ Customer Reviews, The Best Commercial Slush Machine, According to Thousands of Customer Reviews, The Best Expandable Garden Hose, According to 102,500+ Customer Reviews, Apple's New Software Lets You Buy Gas from the Comfort of Your Car, Molded Products Manufacturer Announces $5 Million Expansion, Easter Island's Statues Have Bodies Beneath the Surface, Dealing With Food Waste in the Supply Chain. The potential is there for this to happen for every cylinder you try to control with a needle valve type flow control. There are two types of flow control valves: Meter-out Valve and Meter-in Valve. Meter-out Valve this is the most commonly used type. An undesirable result when the intent was to control the rod movement. flow control hydraulic valves Needle valves are adjustable orifices that restrict flow (speed) in both directions (Fig. If the fitting is replaced or improperly installed on a different port, the resulting fault may consume significant troubleshooting time to identify the cause. These valves are efficiently configured to fit the modifications in system pressure and temperature. Stay up to date on industry news and trends, product announcements and the latest innovations. Flow controls (Fig. In order to get air pressure within an appropriate pressure range, the pressure should be set low enough so that it can fluctuate between 3 and 5 psi without altering the minimum and maximum pressure system requirements. The hole of the ball is open when it aligns with the flow of medium heading through the valve, pivoted typically by a 90-degree turn. valve control pneumatic diagram fisher schematic actuator air pressure citizendium milton pd main California Do Not Track Notice.

While other types offer throttling capabilites and can be used to regulate the flow of air. The terms speed control and flow control are often used interchangeably to identify a valve with the primary function of limiting the velocity of an actuator. We also provide Considering the flow control requirements is the most vital factor to think about before selecting the type of flow control valve need for a specific system application. The gates operation is perpendicular to the medium, the gate moves upwards to open the valve or downwards to close the valve and create a seal with the seats. Custom linear motion potentiometers that can be mounted on your system are the way to go when you want to streamline your motorized flow control valves. At the same time that is happening the air that is in the other end of the air, the cylinder must exhaust out the other line, and through the flow control in that now exhaust airline.

- 2019 Kia Sportage Subwoofer

- 24 Hour Printing Chicago

- Aluminum Brake Rental Near Me

- H13 True Hepa Filter Covid

- How To Make Press On Nails With Gel

- Alpha-h Liquid Gold Side Effects

- 4 Inch Shower Arm Brushed Nickel

- 96'' X 48 Whiteboard With Stand

- Alpinestars Vector Tech Elbow Protector

- Pool Suction Cleaners

- Keeley Red Dirt Vs Super Phat Mod

- 5 Hp Irrigation Pump Single Phase