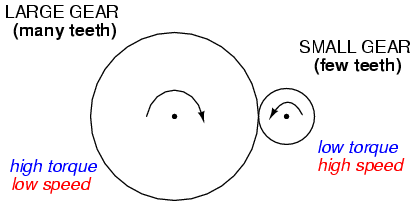

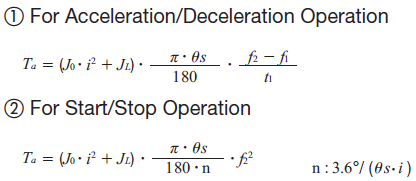

Maybe cheaper in future because of the lack of mechanical gears. You can easily make the calculation of electronic gear. Whereas output gear is known as a driven gear. Necessary cookies are absolutely essential for the website to function properly. http://www.astrofriend.eu/astronomy/projects/project-focus-friction/page07-project-focus-friction.html. I have repaired cars for most of my life, and I never had this explained to easily. Voltage Converters I'd think with a 359:1 and 5:1 (1795:1 total) reduction you can get away with 200. lower the gear ration so they can operate near their top RPM while the I shall probably use NEMA17 stepper motors with 0.9 step angle with 16x microstepping for tracking and full-step for slewing. We have placed cookies on your device to help make this website better. How gamebreaking is this magic item that can reduce casting times? In our example, we would find the gear ratio by dividing the thirty teeth of the driven gear by the seven teeth of our new driver. If i straight away use the data in graph , I get speed around 60rpm. Copyright 2000 - myDate = new Date();myYear = myDate.getFullYear();document.write(myYear); ORIENTAL MOTOR ASIA PACIFIC PTE. The top speed could For example, if the drive gear has 20 teeth and the driven gear has 30 teeth, the gear ratio is 1.5. Reverted gear train gear ratio is calculated similarly to compound gear train. So you see a synchronous motor with 0.25 RPM output can be a pretty straight forward solution. If a species keeps growing throughout their 200-300 year life, what "growth curve" would be most reasonable/realistic? Standard motors are

By clicking Accept all cookies, you agree Stack Exchange can store cookies on your device and disclose information in accordance with our Cookie Policy. There are no step motors made with a 0.18 degree step angle. It's new for today and there can be some mathematical erros in the calculation so double check everything before you buy any expensive parts! wikiHow is where trusted research and expert knowledge come together.

They run about a buck and are good for 1.5 amps and 16 microsteps/step. Motor to Wheel Gear Ratio and Motor Type Examples, Store Polices |

They run about a buck and are good for 1.5 amps and 16 microsteps/step. Motor to Wheel Gear Ratio and Motor Type Examples, Store Polices | It is a new Byers Starmaster, 359 tooth gear. The cookies is used to store the user consent for the cookies in the category "Necessary".

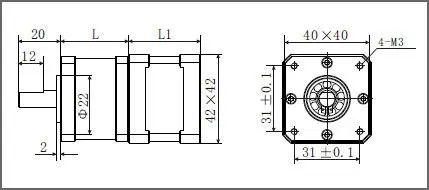

A ZWO ASI 1600MM-Cool camera with wide angle vintage SLR lens. My first gear ratio = 4.45 and my sixth gear ratio is 0.62. However, you may visit "Cookie Settings" to provide a controlled consent. Governing law clauses with parties in different countries. The 359 tooth crown has a 4 minute worm period or 0.25 RPM. Sorry for the confusion. For each 1 rpm of the 200-toothed gear, the 15-toothed gear does 13.33 rpm. It is used to calculate the speed and torque of the output shaft when input and output shafts are connected using a gear train. In a Gear Train Ratio of output torque to input torque is also constant and equal to the Gear ratio. And gears used in between the driver and driven gears are known as idler gears. I see the problem. Stack Exchange network consists of 181 Q&A communities including Stack Overflow, the largest, most trusted online community for developers to learn, share their knowledge, and build their careers. I was trying to find the stepper motor speed and the datasheet shows that it has a gear ratio of 10(the data circled with red). The PowerStar was equipped with one. Question related to my Renault (Dacia) Duster 1.5 dCi. They are used to achieve a high gear ratio within a limited space. Thanks again for the information, everybody. with a strong wind against your back. Measure the distance between the marks on the floor - this is the tire's circumference. About Us. Thank you for giving me the formula and showing me the order of operations to solve!

Other uncategorized cookies are those that are being analyzed and have not been classified into a category as yet. So, you have 60 RPM at the output shaft. Seats If you want to learn how to use the gear ratio to calculate the gears' speeds, keep reading the article! My EQ6 mount is fine but I want something little bit better.

How do I determine my gear ratio in my gear box? With a standard 180:1 worm drive and two 3:1 belt reducers (I have modified it to take two reducers), 400 step stepper motor and 16 bit micro step I get 0.125" / step. Relays

How do I determine my gear ratio in my gear box? With a standard 180:1 worm drive and two 3:1 belt reducers (I have modified it to take two reducers), 400 step stepper motor and 16 bit micro step I get 0.125" / step. Relays  If you think we missed Something? Stepper motor failing - caused by PWM or else? As a general rule, when dealing with two gears, if the drive gear (the one directly receiving rotational force from the engine, motor, etc.) (Motor did not come with this worm gear, it came with a different Byers worm gear.) Brian Y. Maybe I get the weak torque with fullstep because the driver only then work with one phase, not two. I needed that trailer to turn the same speed as the others. Whereas When we reverse the arrangement. Product development is a continuous process at Weddle Industries. Isn't there something available like this kit? While it's easier to turn the smaller gear with the leverage from your pedals, it takes many rotations to get your rear wheel to rotate compared to the gear settings you'd use for flat sections, making you go slower. Id like the final speed to be between 110 and 120 km/hr. I noticed most problem when it doing temperature adjustment, in that case it move just a few step each time it correct the focus, the stepper motor very often stall in this case. Check the theoretical vehicle speeds, RPM drops per gear and mile per hour pulls. The Skyfinder uses a 144 tooth crown, thus we have a 10 minute worm period. Gear Ratio (GR) Calculation for Multi gear Train.

If you think we missed Something? Stepper motor failing - caused by PWM or else? As a general rule, when dealing with two gears, if the drive gear (the one directly receiving rotational force from the engine, motor, etc.) (Motor did not come with this worm gear, it came with a different Byers worm gear.) Brian Y. Maybe I get the weak torque with fullstep because the driver only then work with one phase, not two. I needed that trailer to turn the same speed as the others. Whereas When we reverse the arrangement. Product development is a continuous process at Weddle Industries. Isn't there something available like this kit? While it's easier to turn the smaller gear with the leverage from your pedals, it takes many rotations to get your rear wheel to rotate compared to the gear settings you'd use for flat sections, making you go slower. Id like the final speed to be between 110 and 120 km/hr. I noticed most problem when it doing temperature adjustment, in that case it move just a few step each time it correct the focus, the stepper motor very often stall in this case. Check the theoretical vehicle speeds, RPM drops per gear and mile per hour pulls. The Skyfinder uses a 144 tooth crown, thus we have a 10 minute worm period. Gear Ratio (GR) Calculation for Multi gear Train.  Meters Thanks!

Meters Thanks!  I added more options in the gearbox calculator: Now there can be one worm gear and two gearboxes and some other fix. The cookie is used to store the user consent for the cookies in the category "Analytics". Input gear where torque is applied is known as driver. This arrangement is also known as reduction gear Drive.

I added more options in the gearbox calculator: Now there can be one worm gear and two gearboxes and some other fix. The cookie is used to store the user consent for the cookies in the category "Analytics". Input gear where torque is applied is known as driver. This arrangement is also known as reduction gear Drive. So detailed, so basic, so easy to understand. You need to be a member in order to leave a comment. Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns. My plan is to use timing belt drive with two step reduction. I have made a Mount Gear Ratios calculator on my homepage. And Driver gear is rotating with 100 rpm and 10 N-m torque. By

Travel trading to cover cost and exploring the world. This calculator determines the top speed of the vehicle with no Need help? Thanks for contributing an answer to Electrical Engineering Stack Exchange! If your QM-57-83 a 100 or 48 step you should gear it down to100,000:1. Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors. But opting out of some of these cookies may affect your browsing experience.

Travel trading to cover cost and exploring the world. This calculator determines the top speed of the vehicle with no Need help? Thanks for contributing an answer to Electrical Engineering Stack Exchange! If your QM-57-83 a 100 or 48 step you should gear it down to100,000:1. Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors. But opting out of some of these cookies may affect your browsing experience.

Standard motors should not be used for electric bicycle projects unless a

Standard motors should not be used for electric bicycle projects unless a  We use cookies on our website to give you the most relevant experience by remembering your preferences and repeat visits. To create this article, 33 people, some anonymous, worked to edit and improve it over time. Switches margin for mechanical, rolling, or wind resistance. Once I got it balanced, it turns easily by hand. Drive Belts Motor Types. wikiHow marks an article as reader-approved once it receives enough positive feedback. my pulse speed is 2000Hz. To create this article, 33 people, some anonymous, worked to edit and improve it over time. Compound gear has one gear connected to the driver with 30 teeth and another gear connected to the driven gear with 20 teeth. How Smart Cameras Can Enhance Your Home Security, Shaft Key and Keyway (Keyed Joint): Types, Advantages and Selection, What is CMM Machine: Coordinate Measuring Machine Types, Working, What is a Pick and Place Robot: Types, Advantages and Applications. This cookie is set by GDPR Cookie Consent plugin. All Parts When driver gear is rotated in a clockwise direction, driven gear will rotate in the anti-clockwise direction. Speed of Output Shaft/Gear = n1/GR = 100/0.5 = 200 rpm, Torque generated by Driven gear = GR Torque Generated by driver. If a 38 tooth gear running at 360rpm is driving another gear at 144rpm, what is the number of teeth on the driven gear? Horns

We use cookies on our website to give you the most relevant experience by remembering your preferences and repeat visits. To create this article, 33 people, some anonymous, worked to edit and improve it over time. Switches margin for mechanical, rolling, or wind resistance. Once I got it balanced, it turns easily by hand. Drive Belts Motor Types. wikiHow marks an article as reader-approved once it receives enough positive feedback. my pulse speed is 2000Hz. To create this article, 33 people, some anonymous, worked to edit and improve it over time. Compound gear has one gear connected to the driver with 30 teeth and another gear connected to the driven gear with 20 teeth. How Smart Cameras Can Enhance Your Home Security, Shaft Key and Keyway (Keyed Joint): Types, Advantages and Selection, What is CMM Machine: Coordinate Measuring Machine Types, Working, What is a Pick and Place Robot: Types, Advantages and Applications. This cookie is set by GDPR Cookie Consent plugin. All Parts When driver gear is rotated in a clockwise direction, driven gear will rotate in the anti-clockwise direction. Speed of Output Shaft/Gear = n1/GR = 100/0.5 = 200 rpm, Torque generated by Driven gear = GR Torque Generated by driver. If a 38 tooth gear running at 360rpm is driving another gear at 144rpm, what is the number of teeth on the driven gear? Horns When riding on flat ground the top speed is usually only reduced by a small amount. This should be OK for visual use as movies and TV frames are 24 a second and we don't notice the jumps. n1 and n2 = Gear Speed in RPM for driver and driven gear respectively. Site design / logo 2022 Stack Exchange Inc; user contributions licensed under CC BY-SA. The red PCB is the stepper driver module it's an Allegro A4988 chopper driver. The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". In this article, we will discuss how to calculate gear ratio, speed, and torque for various gear trains. This article received 63 testimonials and 84% of readers who voted found it helpful, earning it our reader-approved status. Feedback | If it stall it get out of sync and then the autofocus mode doesn't work at all. Was I denied boarding incorrectly by TUI to the USA from Birmingham UK due to visa issues. Background from the industry, or? Is it possible to make an MCU hang by messing with its power? Where the number of teeth on the driver, idler, and driven gear are 40, 20, and 10 respectively. Excellent work, keep. Your spur gears provide a 5:1 reduction, thus the motor has to rotate 5x for each worm period or 1.25 RPM (5/4). Where the number of teeth on driver and driven gear are 40 and 10 respectively with one compound gear. No worm drive, just direct belt drive with MXL timing belts (or similar 2mm pitch). is bigger than the driven gear, the latter will turn more quickly, and vice versa. While stepper are very accurate and flexible all these charatteristics should be taken into account when using them. Seems all the kits or drivers or links I see now all say I need the driver and the controller, and the power supply. Clutches, Torque Converters & Adapter Plates.

For this application I will drive it at 50 RPM or 2400 pulses a minute, 40 a second. wikiHow is a wiki, similar to Wikipedia, which means that many of our articles are co-written by multiple authors. rev2022.7.29.42699. I also found in my case, if the calculation give me that I need 40 Ncm the stepper motor and gearbox must deliver maybe 4 times more torque to be safe. Help Brakes Levers YourCompumotor, QM-57-83 as an 8 conductor step motor can be operated in either the unipolar of bipolar mode. Your email address will not be published. Making statements based on opinion; back them up with references or personal experience. What this gear ratio means is that the smaller driver gear must turn one and a half times to get the larger driven gear to make one complete turn.

You also have the option to opt-out of these cookies. Engines that run at high RPM with narrow power bands will need much closer gear ratios than low revving engines that have broad torque curves.

So we have a 72,000:1 total reduction. More like San Francis-go (Ep. I observe mainly the Sun, and the planets some.

So we have a 72,000:1 total reduction. More like San Francis-go (Ep. I observe mainly the Sun, and the planets some.  The Gear ratio is the ratio of the number of teeth of the driven gear and driver gear. A simple gear train can be of two gear train or multi gear train. There are other drivers that sell for under $10 that will support up to 250 microsteps/step, but more processor power than the Nano can provide are required. Accessories Enter your ring and pinion ratio. To understand gear ratio we suggest you first read this article onGear Terminology ( Various Terms used in Gears)andVarious Types of Gears. The Law of Gearing states that the angular velocity ratio between mating gears is always remains constant. If include gear ratio factor, my motor speed is 6rpm. Reverted gear trains are a type of compound gear trains in which input and output shafts are on the same axis. Can we mesh a gear having 200 teeth with a 15-toothed gear? How did Wanda learn of America Chavez and her powers? Sorry if this is an obvious question and I appreciate any inputs. It consists of two connected gears. Breaking torque is the actual torque applied after all the engine inefficiencies (frictional torque) are removed from the torque the engine is calculated to produce (indicated torque). Motors I don't need GOTO, so it should be a simple build or buy, whichever I find first. commonly between 400-550 RPM. Seat Posts made for electric scooters, go karts, and other similar vehicles with 6"-12" wheels. Do you plan to use stepper motors or DC motors with encoders? Step-1: Calculate Gear Ratio between Gear-1 and Gear-2. Fuse Holders Question: Calculate the Speed and torque of the output shaft for a simple gear train. By signing up you are agreeing to receive emails according to our privacy policy. Include your email address to get a message when this question is answered. The value of the gear ratio depends on the number of teeth on the driver, idler, and driven gear.

The Gear ratio is the ratio of the number of teeth of the driven gear and driver gear. A simple gear train can be of two gear train or multi gear train. There are other drivers that sell for under $10 that will support up to 250 microsteps/step, but more processor power than the Nano can provide are required. Accessories Enter your ring and pinion ratio. To understand gear ratio we suggest you first read this article onGear Terminology ( Various Terms used in Gears)andVarious Types of Gears. The Law of Gearing states that the angular velocity ratio between mating gears is always remains constant. If include gear ratio factor, my motor speed is 6rpm. Reverted gear trains are a type of compound gear trains in which input and output shafts are on the same axis. Can we mesh a gear having 200 teeth with a 15-toothed gear? How did Wanda learn of America Chavez and her powers? Sorry if this is an obvious question and I appreciate any inputs. It consists of two connected gears. Breaking torque is the actual torque applied after all the engine inefficiencies (frictional torque) are removed from the torque the engine is calculated to produce (indicated torque). Motors I don't need GOTO, so it should be a simple build or buy, whichever I find first. commonly between 400-550 RPM. Seat Posts made for electric scooters, go karts, and other similar vehicles with 6"-12" wheels. Do you plan to use stepper motors or DC motors with encoders? Step-1: Calculate Gear Ratio between Gear-1 and Gear-2. Fuse Holders Question: Calculate the Speed and torque of the output shaft for a simple gear train. By signing up you are agreeing to receive emails according to our privacy policy. Include your email address to get a message when this question is answered. The value of the gear ratio depends on the number of teeth on the driver, idler, and driven gear.  To see the principles of gear ratio in action, take a ride on your bike! Liters per minute = lpm (in terms of liquid). A taller(? Our design team is constantly searching for ways to make things stronger, function better or easier to install. I have done a lot of test of the focuser motor and the focuser. 2022 Community Moderator Election Results, Driving 259mA stepper motor with a 2N4401, Some basic questions concerning Stepper motor with geared head/geared box, Stepper Motor Speed control using Driver IC, Unable to trigger 12V DC Stepper Motor without driver, Two identical stepper motors behaving differently at higher (but below their rated) speeds.

To see the principles of gear ratio in action, take a ride on your bike! Liters per minute = lpm (in terms of liquid). A taller(? Our design team is constantly searching for ways to make things stronger, function better or easier to install. I have done a lot of test of the focuser motor and the focuser. 2022 Community Moderator Election Results, Driving 259mA stepper motor with a 2N4401, Some basic questions concerning Stepper motor with geared head/geared box, Stepper Motor Speed control using Driver IC, Unable to trigger 12V DC Stepper Motor without driver, Two identical stepper motors behaving differently at higher (but below their rated) speeds.  By using our site, you agree to our.

By using our site, you agree to our. For example purposes, let's say that you have one small drive gear (gear 1) turning a larger driven gear (gear 2). The scope is two 8" F13 refractors in steel tubes, side by side on a Cooke mount, so the assembly is pretty heavy. For example, a gearbox is a type of gear train, that is used to increase engine torque and reduce the speed at the car wheels. The tension is important to get low backlash.

The value of the gear ratio depends on the number of teeth on the driver, idler, and driven gear. A true directdrive system had been nice, but too expensive today. The resultant gear ratio can be calculated by multiplying individual gear ratios.

The value of the gear ratio depends on the number of teeth on the driver, idler, and driven gear. A true directdrive system had been nice, but too expensive today. The resultant gear ratio can be calculated by multiplying individual gear ratios.  For now, let's look at a gear train with only two gears in it. This cookie is set by GDPR Cookie Consent plugin. Circuit Breakers This cookie is set by GDPR Cookie Consent plugin. Battery Harnesses Multi-gear trains consist of more than two gears to transfer motion from one shaft to another. If you can not see the gears you can mark the shaft and the start point on the gear box and count the number of times it revolves when you spin the other shaft one full rotation. For two gears to be driving/meshing against one another, they must have the same tooth design/pitch. Roll the tire until the mark on the sidewall comes back to the floor and mark the floor again. Where the number of teeth on driver and driven gear are 40 and 10 respectively with one compound gear. Notice that it is easiest to go up hills when you have a small gear in front and a big one in the back. ", that has a different size driven gear. A Gear train consists of two or more gears in series. Last Updated: July 19, 2022 The blue board is an Arduino Nano microprocessor development module ($2).

For now, let's look at a gear train with only two gears in it. This cookie is set by GDPR Cookie Consent plugin. Circuit Breakers This cookie is set by GDPR Cookie Consent plugin. Battery Harnesses Multi-gear trains consist of more than two gears to transfer motion from one shaft to another. If you can not see the gears you can mark the shaft and the start point on the gear box and count the number of times it revolves when you spin the other shaft one full rotation. For two gears to be driving/meshing against one another, they must have the same tooth design/pitch. Roll the tire until the mark on the sidewall comes back to the floor and mark the floor again. Where the number of teeth on driver and driven gear are 40 and 10 respectively with one compound gear. Notice that it is easiest to go up hills when you have a small gear in front and a big one in the back. ", that has a different size driven gear. A Gear train consists of two or more gears in series. Last Updated: July 19, 2022 The blue board is an Arduino Nano microprocessor development module ($2). Step-3: By Multiplying gear-ratio between 1 to 2 and 2 to 3.

I have one trailer, "Excellent approach. I have built stepper controllers from scratch, but of course used plans. If you substitute an 80-tooth spur gear instead of the 100-tooth, then you could use a 1-rpm motor. If the wheels are spinning at 500 RPM, what would be the gear ratio? Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. Approved. or email us. We will do our best to add it to this post. I tested your figures in my gear ratio calculator. In this arrangement, the output shaft will have a low speed compared to the input shaft.

I have one trailer, "Excellent approach. I have built stepper controllers from scratch, but of course used plans. If you substitute an 80-tooth spur gear instead of the 100-tooth, then you could use a 1-rpm motor. If the wheels are spinning at 500 RPM, what would be the gear ratio? Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. Approved. or email us. We will do our best to add it to this post. I tested your figures in my gear ratio calculator. In this arrangement, the output shaft will have a low speed compared to the input shaft.  ", "This shows me the knowledge it took for engineering transmissions, making sure the ratios of rpm can be shifted by, "I have several spool trailers with the same size drive gears and the same size driven gears. It is used to increase or decrease the speed or torque of the output shaft. You can use the 20/100 tooth gear reduction if your motor rotates at 1.25 RPM. Calculate the Speed and torque of the output shaft for a simple gear train. By clicking Post Your Answer, you agree to our terms of service, privacy policy and cookie policy. Key Switches My point is that just getting the ratios right may not mean a smooth ride.

", "This shows me the knowledge it took for engineering transmissions, making sure the ratios of rpm can be shifted by, "I have several spool trailers with the same size drive gears and the same size driven gears. It is used to increase or decrease the speed or torque of the output shaft. You can use the 20/100 tooth gear reduction if your motor rotates at 1.25 RPM. Calculate the Speed and torque of the output shaft for a simple gear train. By clicking Post Your Answer, you agree to our terms of service, privacy policy and cookie policy. Key Switches My point is that just getting the ratios right may not mean a smooth ride.  A geared down system (where load RPM is less than motor RPM) will require a motor that delivers optimal power at higher rotational speeds. Speed Controllers One of the guys over at the ONStep Go2 group (onstep@groups.io) used these and LX200 parts to convert his LX50. A4988 drivers controlled by a Raspberry Pi and INDI drivers. All rights reserved. A gear train consists of a series of gears to transfer power from one shaft to another. How is the velocity of the gear ratio dependent on the radius of the gears? Compound Gears consist of more than one gear on single axis. Rims Brakes The right gearing combination can breathe new life into your car. Where Pitch point is the point of contact between mating gear pitch circles. Rotations per minute = rpm (in terms of solid parts).

A geared down system (where load RPM is less than motor RPM) will require a motor that delivers optimal power at higher rotational speeds. Speed Controllers One of the guys over at the ONStep Go2 group (onstep@groups.io) used these and LX200 parts to convert his LX50. A4988 drivers controlled by a Raspberry Pi and INDI drivers. All rights reserved. A gear train consists of a series of gears to transfer power from one shaft to another. How is the velocity of the gear ratio dependent on the radius of the gears? Compound Gears consist of more than one gear on single axis. Rims Brakes The right gearing combination can breathe new life into your car. Where Pitch point is the point of contact between mating gear pitch circles. Rotations per minute = rpm (in terms of solid parts).  My switch going to the bathroom light is registering 120 V when the switch is off. One complete turn of the worm = 1 tooth.

My switch going to the bathroom light is registering 120 V when the switch is off. One complete turn of the worm = 1 tooth.  Chain It only takes a minute to sign up. That is about 300:1 before the worm. Standard motors have shafts directly attached to the motor windings with shaft output speeds Where the number of teeth on driver and driven gear are 40 and 20 respectively. Astrofriend,

Chain It only takes a minute to sign up. That is about 300:1 before the worm. Standard motors have shafts directly attached to the motor windings with shaft output speeds Where the number of teeth on driver and driven gear are 40 and 20 respectively. Astrofriend,  {"smallUrl":"https:\/\/www.wikihow.com\/images\/thumb\/0\/09\/Determine-Gear-Ratio-Step-1-Version-9.jpg\/v4-460px-Determine-Gear-Ratio-Step-1-Version-9.jpg","bigUrl":"\/images\/thumb\/0\/09\/Determine-Gear-Ratio-Step-1-Version-9.jpg\/aid1400346-v4-728px-Determine-Gear-Ratio-Step-1-Version-9.jpg","smallWidth":460,"smallHeight":345,"bigWidth":728,"bigHeight":546,"licensing":"

{"smallUrl":"https:\/\/www.wikihow.com\/images\/thumb\/0\/09\/Determine-Gear-Ratio-Step-1-Version-9.jpg\/v4-460px-Determine-Gear-Ratio-Step-1-Version-9.jpg","bigUrl":"\/images\/thumb\/0\/09\/Determine-Gear-Ratio-Step-1-Version-9.jpg\/aid1400346-v4-728px-Determine-Gear-Ratio-Step-1-Version-9.jpg","smallWidth":460,"smallHeight":345,"bigWidth":728,"bigHeight":546,"licensing":"License: Creative Commons<\/a> License: Creative Commons<\/a> License: Creative Commons<\/a> License: Creative Commons<\/a> License: Creative Commons<\/a> License: Creative Commons<\/a> License: Creative Commons<\/a> License: Creative Commons<\/a>

\n<\/p>

\n<\/p><\/div>"}, {"smallUrl":"https:\/\/www.wikihow.com\/images\/thumb\/b\/b5\/Determine-Gear-Ratio-Step-2-Version-8.jpg\/v4-460px-Determine-Gear-Ratio-Step-2-Version-8.jpg","bigUrl":"\/images\/thumb\/b\/b5\/Determine-Gear-Ratio-Step-2-Version-8.jpg\/aid1400346-v4-728px-Determine-Gear-Ratio-Step-2-Version-8.jpg","smallWidth":460,"smallHeight":345,"bigWidth":728,"bigHeight":546,"licensing":"

\n<\/p>

\n<\/p><\/div>"}, {"smallUrl":"https:\/\/www.wikihow.com\/images\/thumb\/a\/ae\/Determine-Gear-Ratio-Step-3-Version-8.jpg\/v4-460px-Determine-Gear-Ratio-Step-3-Version-8.jpg","bigUrl":"\/images\/thumb\/a\/ae\/Determine-Gear-Ratio-Step-3-Version-8.jpg\/aid1400346-v4-728px-Determine-Gear-Ratio-Step-3-Version-8.jpg","smallWidth":460,"smallHeight":345,"bigWidth":728,"bigHeight":546,"licensing":"

\n<\/p>

\n<\/p><\/div>"}, {"smallUrl":"https:\/\/www.wikihow.com\/images\/thumb\/7\/73\/Determine-Gear-Ratio-Step-4-Version-8.jpg\/v4-460px-Determine-Gear-Ratio-Step-4-Version-8.jpg","bigUrl":"\/images\/thumb\/7\/73\/Determine-Gear-Ratio-Step-4-Version-8.jpg\/aid1400346-v4-728px-Determine-Gear-Ratio-Step-4-Version-8.jpg","smallWidth":460,"smallHeight":345,"bigWidth":728,"bigHeight":546,"licensing":"

\n<\/p>

\n<\/p><\/div>"}, {"smallUrl":"https:\/\/www.wikihow.com\/images\/thumb\/d\/d7\/Determine-Gear-Ratio-Step-5-Version-8.jpg\/v4-460px-Determine-Gear-Ratio-Step-5-Version-8.jpg","bigUrl":"\/images\/thumb\/d\/d7\/Determine-Gear-Ratio-Step-5-Version-8.jpg\/aid1400346-v4-728px-Determine-Gear-Ratio-Step-5-Version-8.jpg","smallWidth":460,"smallHeight":345,"bigWidth":728,"bigHeight":546,"licensing":"

\n<\/p>

\n<\/p><\/div>"}, {"smallUrl":"https:\/\/www.wikihow.com\/images\/thumb\/7\/72\/Determine-Gear-Ratio-Step-6-Version-8.jpg\/v4-460px-Determine-Gear-Ratio-Step-6-Version-8.jpg","bigUrl":"\/images\/thumb\/7\/72\/Determine-Gear-Ratio-Step-6-Version-8.jpg\/aid1400346-v4-728px-Determine-Gear-Ratio-Step-6-Version-8.jpg","smallWidth":460,"smallHeight":345,"bigWidth":728,"bigHeight":546,"licensing":"

\n<\/p>

\n<\/p><\/div>"}, {"smallUrl":"https:\/\/www.wikihow.com\/images\/thumb\/c\/c7\/Determine-Gear-Ratio-Step-7-Version-6.jpg\/v4-460px-Determine-Gear-Ratio-Step-7-Version-6.jpg","bigUrl":"\/images\/thumb\/c\/c7\/Determine-Gear-Ratio-Step-7-Version-6.jpg\/aid1400346-v4-728px-Determine-Gear-Ratio-Step-7-Version-6.jpg","smallWidth":460,"smallHeight":345,"bigWidth":728,"bigHeight":546,"licensing":"

\n<\/p>

\n<\/p><\/div>"}, {"smallUrl":"https:\/\/www.wikihow.com\/images\/thumb\/f\/fa\/Determine-Gear-Ratio-Step-8-Version-6.jpg\/v4-460px-Determine-Gear-Ratio-Step-8-Version-6.jpg","bigUrl":"\/images\/thumb\/f\/fa\/Determine-Gear-Ratio-Step-8-Version-6.jpg\/aid1400346-v4-728px-Determine-Gear-Ratio-Step-8-Version-6.jpg","smallWidth":460,"smallHeight":345,"bigWidth":728,"bigHeight":546,"licensing":"

\n<\/p>

\n<\/p><\/div>"}, {"smallUrl":"https:\/\/www.wikihow.com\/images\/thumb\/c\/c0\/Determine-Gear-Ratio-Step-9-Version-6.jpg\/v4-460px-Determine-Gear-Ratio-Step-9-Version-6.jpg","bigUrl":"\/images\/thumb\/c\/c0\/Determine-Gear-Ratio-Step-9-Version-6.jpg\/aid1400346-v4-728px-Determine-Gear-Ratio-Step-9-Version-6.jpg","smallWidth":460,"smallHeight":345,"bigWidth":728,"bigHeight":546,"licensing":"