Close attention is paid to airflow and materials conductivity during the design phase. Metalloids are on the borderline between metals and other materials. In many applications, it is needed to produce a bimetal with a snap operation with a sudden change of shape at a given temperature. Many oils are used. Industrial temperature sensors utilizing the expansion of a liquid to control temperature are often called capillary thermostats. ), ( Waxes have the characteristic increase in volume when they melt. ZAC de la Bonne Rencontre, An alloy of tin, antimony, lead, bismuth and other metals, will have melting temperatures between 25 and 200 C depending of the percentage of each ingredient. This increase in pressure may be due to local boiling in a capillary thermostat diastat. When the strip is heated, it bends proportionally to the temperature. However, it must used in protected devices, without contact with air or water, because it is par- ticularly reactive, flammable or explosive in contact with them. When the leads are disconnected from the indicator, the temperature of the cockpit area around the instrument panel can be read on the indicator dial. 2 When the test switch is operated, an overtemperature signal is simulated in each indicator temperature control bridge circuit. The design of a diastat tends to minimize this movement, by limiting the volume of liquid in (C) and (D) by 2 ways: The counterpart of this design of the bellows with a small amount of liquid when filling the diastat is that no mechanical movement is possible below this filling temperature. The expansion forces are very important and will develop considerable power to the mechanisms. As the two coils produce their magnetic fields, the stronger field interacts and pivots downward into the weaker, less concentrated part of the permanent magnet field, while the weaker coil magnetic field shifts upward toward the more concentrated flux field of the large magnet. ), Learning Instrumentation And Control Engineering, Industrial Motor Starters and Starting Methods, Electrical Protection of 3 phase Motors: Types and Protection Schemes, Understanding the Technical Specifications on the Nameplate of Solar Panels, A Guide to Solar Panels Power Installations, How to Specify Electric Motors for Hazardous Locations, Understanding Battery Technical Specifications, Instrumentation Books for Instrument Engineers and Technicians, Sizing Orifice Plates with Daniel Flow Calculator. Typical thermocouple temperature indicators, Figure 9. Since the electromotive force set up in the circuit varies with the difference in temperature between the hot and cold junctions, it is necessary to compensate the indicator mechanism for changes in cockpit temperature which affect the cold junction. For example, the freezing point of water at 0 C causes an increase in volume, melting at 0 C causes a reduction in volume, but also the transition from the solid state to the liquid state : when water is boiling at 100 C steam causes large volume increase. Here, the change in pressure with temperature (as described by the Ideal Gas Law: PV = nRT) allows us to sense the bulbs temperature. How a Current to Pressure Transducer Works, Common Symbols Used in Process and Instrumentation Diagrams, How to Measure Electric Motor Insulation Resistance, How to Test 3-phase AC Motor Windings with an Ohmeter, How to Read Torque Speed Characteristics of AC Motors, Instrument Abbreviations Used in Instrumentation Diagrams, How to Convert Thermocouple Milivolts to Temperature, Principles & Formulas for Flow Measurement. The size of the bulb is not critical and in fact can be sized quite large for averaging measurements in large volumes such as dryers and ovens. TAT sensor/probe design is complicated by the potential of ice forming during icing conditions. By limiting the capillary internal The minimum diameter is a compromise between the technological possibilities of embodiment of the capillaries, the stresses due to bending of the capillary, and the water pressure losses permissible depending on the viscosity of the liquid used, and the pressure developed by the expansion. Unfortunately gases are compressible, and even if it is possible to obtain significant movements, the available force is low. The range of operation is determined by the initial filling pressure. This adjusts the zeroing spring tension of the pointer when the bridge is at the balance point (the position at which the bridge circuit is balanced and no current flows through the meter). But they can be wound in a spiral shape, although this arrangement most often used in the construction of thermometers. In this closed environment, any increase in temperature results in an increase in pressure and significant volume changes. An external test switch is usually installed so that over temperature warning lights for all the engines can be tested at the same time. The vapour filled system uses a volatile liquid/vapor combination to generate a temperature-dependent fluid expansion. This application is limited to a few specific uses, such as rice cookers. They are used in capillary thermostats and membranes room thermostat. Fully compensated liquid expansion systems are expensive and complex. The overtemperature warning light in the indicator illuminates when the TIT reaches a predetermined limit. This makes the device more accurate. a certain temperature, return to the form they had before their mechanical processing.

Using the same metal for the outer tube and the inner rod provides controls that are only responsive to fast changes in temperature and are used in fire detectors.

Their first applications were opening the steam pressure locomotive blowdown valve. Since 1958, we have been committed to exceeding our customers expectations by providing an unparalleled level of customer service and local technical support. They are simple to use and allow precise, permanentcalibration making them ideal for reference use.

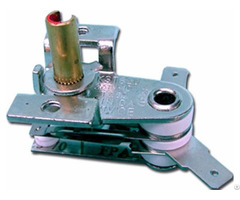

[Figure 8] Numeric LED indictors for CHT are also common in modern aircraft. This system is mainly used for the production of thermometer, because the available forces are weak and can hardly operate a contact.  A bimetallic outside air temperature gauge and its installation on a light aircraft, Figure 3. This system, which causes a high displacement, is used for car thermostats, to open the flow path of water. ), ( This produces varying magnetic fields. They are: Class I systems use a liquid fill fluid. {getWidget} $results={5} $label={recent} $type={list1}, Sources of Power for Gyroscopic Instruments, Figure 1. The ratio of the drift therefore not only reports to the initial volume inside the bellow, but increase with the temperatures as this volume increases with the temperature rise on the bulb. This principle is the basis of most current water heater thermostats. Numerous thermocouples can be used with the average voltage representing the TIT. Through the use of expandable metal instead of Invar, it is possible to obtain devices with anticipative control action, which is very close to proportional action of electronic controllers. Therefore, no current flows in the galvanometer leg of the circuit. Total air temperature (TAT) probes. What is used is the instant change of volume that appears at specific temperatures at melting, freezing, and boiling points on various elements. Over range protection is of particular concern in liquid filled systems, and is typically 100% over the normal operating range. Diaphragms expansion ranges are between 0.4 and 0.8mm for the entire measuring range. Oil temperature is sometimes measured this way. Mechanical temperature sensors rely on the expansion and contraction of a sensing element (usually a metal, or a confined liquid or gas) to measure changes in temperature. This allows to make thermostats sensitive to temperature on a long distance, detecting hot spot at any place on the capillary. Sometimes it uses a modified form of the Wheatstonebridge circuit. 9 2009 - 2022 instrumentationtoolbox.com. Expansions value are similar as the cartridges. Heat treatment and composition determine these temperatures. The rods are formed of an outer expandable tube in stainless steel, copper or brass, and an inner invar rod. These also have the added advantage of using smaller bulbs. Most gasses, liquids and solids expand in volume as their temperature is increased and shrink involume as their temperature is decreased (with the notable exception of water which grows a little after it freezes). On the bellows: When filling the diastat, the two membranes forming the bellows are pressed against each other, without gap, and thus only a small amount of fluid can go between However the volume of liquid in the bellows increases progressively as the liquid in the bulb (A) expands by the temperature rise. Gas filled systems do provide a faster response than other filled devices, and as it converts temperature directly into pressure it is particularly useful in pneumatic systems. Movement of the diaphragm or bellows can be used to close or open an electrical circuit through a switch or directly control the flow of a liquid or gas (refrigerant or steam, for example) through the use of a valve. The capillary thermostat operates on the principle of fluid expansion. The cartridge consists of an outer expandable tube, usually stainless steel, and two non-expandable internal blades, usually Invar. Thosewhich are mechanical and those which are electrical in function. Different cockpit TAT displays, Figure 12. A temperature change in a fluid filled sensing system consisting of probe (also called bulb), capillary and diaphragm capsule, produces a volume change. ), ( [Figure 12]. The best-known application is the control of the sprinkler systems, common in building fire detection. ), ( The bulb (A), which is the reservoir of the largest portion of the liquid, and witch expansion as a function of temperature will be used to measure It is closed at its free end by welding after liquid filling. Movements are not linear, and these systems are sensitive to changes in atmospheric pressure. This temperature can be changed by altering the composition of the magnetic alloy. The magnetic pole ends of the permanent magnet are closer at the top than they are at the bottom. There are basically four types of filled bulb temperature sensors in use in industrial applications. In this simple form, however, thermometers of this type do not offer the ability to provide feedback to control temperature. Its first use was the traditional mercury thermometer. We use cookies to ensure that we give you the best experience on our website. 7 A very rigorous selection of the composition, thickness, depths of stamping and heat treatment, is requested to obtaining accurate, stable and repetitive operating temperature. 4 At this temperature there occurs a high volume change. 6

A bimetallic outside air temperature gauge and its installation on a light aircraft, Figure 3. This system, which causes a high displacement, is used for car thermostats, to open the flow path of water. ), ( This produces varying magnetic fields. They are: Class I systems use a liquid fill fluid. {getWidget} $results={5} $label={recent} $type={list1}, Sources of Power for Gyroscopic Instruments, Figure 1. The ratio of the drift therefore not only reports to the initial volume inside the bellow, but increase with the temperatures as this volume increases with the temperature rise on the bulb. This principle is the basis of most current water heater thermostats. Numerous thermocouples can be used with the average voltage representing the TIT. Through the use of expandable metal instead of Invar, it is possible to obtain devices with anticipative control action, which is very close to proportional action of electronic controllers. Therefore, no current flows in the galvanometer leg of the circuit. Total air temperature (TAT) probes. What is used is the instant change of volume that appears at specific temperatures at melting, freezing, and boiling points on various elements. Over range protection is of particular concern in liquid filled systems, and is typically 100% over the normal operating range. Diaphragms expansion ranges are between 0.4 and 0.8mm for the entire measuring range. Oil temperature is sometimes measured this way. Mechanical temperature sensors rely on the expansion and contraction of a sensing element (usually a metal, or a confined liquid or gas) to measure changes in temperature. This allows to make thermostats sensitive to temperature on a long distance, detecting hot spot at any place on the capillary. Sometimes it uses a modified form of the Wheatstonebridge circuit. 9 2009 - 2022 instrumentationtoolbox.com. Expansions value are similar as the cartridges. Heat treatment and composition determine these temperatures. The rods are formed of an outer expandable tube in stainless steel, copper or brass, and an inner invar rod. These also have the added advantage of using smaller bulbs. Most gasses, liquids and solids expand in volume as their temperature is increased and shrink involume as their temperature is decreased (with the notable exception of water which grows a little after it freezes). On the bellows: When filling the diastat, the two membranes forming the bellows are pressed against each other, without gap, and thus only a small amount of fluid can go between However the volume of liquid in the bellows increases progressively as the liquid in the bulb (A) expands by the temperature rise. Gas filled systems do provide a faster response than other filled devices, and as it converts temperature directly into pressure it is particularly useful in pneumatic systems. Movement of the diaphragm or bellows can be used to close or open an electrical circuit through a switch or directly control the flow of a liquid or gas (refrigerant or steam, for example) through the use of a valve. The capillary thermostat operates on the principle of fluid expansion. The cartridge consists of an outer expandable tube, usually stainless steel, and two non-expandable internal blades, usually Invar. Thosewhich are mechanical and those which are electrical in function. Different cockpit TAT displays, Figure 12. A temperature change in a fluid filled sensing system consisting of probe (also called bulb), capillary and diaphragm capsule, produces a volume change. ), ( [Figure 12]. The best-known application is the control of the sprinkler systems, common in building fire detection. ), ( The bulb (A), which is the reservoir of the largest portion of the liquid, and witch expansion as a function of temperature will be used to measure It is closed at its free end by welding after liquid filling. Movements are not linear, and these systems are sensitive to changes in atmospheric pressure. This temperature can be changed by altering the composition of the magnetic alloy. The magnetic pole ends of the permanent magnet are closer at the top than they are at the bottom. There are basically four types of filled bulb temperature sensors in use in industrial applications. In this simple form, however, thermometers of this type do not offer the ability to provide feedback to control temperature. Its first use was the traditional mercury thermometer. We use cookies to ensure that we give you the best experience on our website. 7 A very rigorous selection of the composition, thickness, depths of stamping and heat treatment, is requested to obtaining accurate, stable and repetitive operating temperature. 4 At this temperature there occurs a high volume change. 6

This type of measurement also has the advantage that there are no moving parts and no electrical stimulation. The good thermal conductivity of liquids used provides short response time. This causes the magnetic field lines of flux between the poles to be more concentrated at the top. They are used for the same reasons as above, but have the disadvantage of being flammable. Process Measurement, Instrumentation & Control Blog, Temperature, Pressure, Vacuum, and Differential Switches, Application of Load Cells in Process Measurement. Lets take a quick look at a few of the types of temperature sensors that are available and suggest where each is applicable in cleaning. In this type of gauge, the sensing bulb is placed in the area needing to have temperature measured. If the temperature of the bulb changes, its resistance also changes, and the bridge becomes unbalanced, causing current to flow through the galvanometer in one direction or the other. * 77860 Quincy Voisins, France, Phone: +33(0)1 60 04 66 44 Thermometers of this type are commonly used to measure the temperature of a liquid or gas in laboratory or domestic settings. At low temperatures and above 400 oC, helium should be considered. In some cases, an insulating material is placed over the sensing bulb on the side opposite to the surface being measured to minimize this potential inaccuracy. The unknown resistance represents the resistance of the temperature bulb of the electrical resistance thermometer system. Its expansion is almost linear from ambient to 500 C. This is an excellent conductor of heat. Thermostats and humidistats, how to select the right knob. We Provide Tools and Basic Information for Learning Process Instrumentation and Control Engineering. Liquid filled systems have the advantage over Mercury in that the expansion of the fluid is about six times that of a Mercury system. Is linear expansion and allows a linear scale in a wide range of temperatures. It is now possible to cover with these 3 types of liquids, ranges from -40 C to 400 C, (Correction factor) of liquid filled bulb and capillary thermostats. A bayonet type thermocouple is installed in a bore in the cylinder wall (B), Figure 8. This is accomplished by using a bimetallic spring connected to the indicator mechanism. The parasite drift of a bulb and capillary thermostat will be given in the data sheet and expressed in C / C or K / K. It depends on the volume ratio between the bulb and capillary + bellows. Here, the volumetric expansion of the liquid drives an indicating mechanism to show temperature as shown below: Liquid expansion systems have narrow spans, small sensors and give high accuracy.

A long capillary tube connects the bulb to the bourdon tube in the instrument housing. The bimetal strip is formed by two co-laminated metal. A resistor with an unknown value [Figure 4D] is also part of the circuit.

This type of measurement is quite simple and low cost. A basic construction of the gas filled system is shown below: Nitrogen is quite commonly used with gas filled systems. The result is that a very small amount of expansion of the mercury in the bulb creates a relatively larger change in how far the mercury is pushed up into thesmall diametertube. First, lets look at mechanical type sensors. Copyright 2016-2022 - JPC sas - All right reserved. Each circuit is electrically independent, providing dual system reliability. ), ( For this, a bimetal disc is bumped and formed into a dome. 5 In order to accurately sense temperature, the bulb of a capillary thermostat needs to be positioned in such a way that the entire bulb is heated or cooled as the temperature being sensed changes. i.e a single pole, single throw normally closed circuit breaks (opens) on rise of temperature. Its use in thermostats is relatively recent, and arose with self-cleaning ovens, because it allows devices withstanding high temperatures.

This form of measurement is based on the vapour-pressure curves of the fluid and measurement occurs at the transition between the liquid and vapour phases. As the sensor bulb resistance varies with temperature, different amounts of current flow through the coils. We offer the most comprehensive line of measurement, control, and communication solutions in the Industry today. ), ( An informative and educational blog specializing in pressure, temperature, level and flow instrumentation, control valves, process analyzers, and all other areas of process measurement. In assembled thermostats, adjusting the set point is not possible below this temperature at which the bellows is empty. 22 These fields interact with the magnetic field of a large permanent magnet, resulting in an indication of temperature, Figure 6. ), ( A TIT indicating system provides a visual indication at the instrument panel of the temperature of gases entering the turbine. Among the main fillers used, there are : They are used because of their availability, and existing vacuum filling systems for refrigerant circuits. Website design and search engine optimization by Upright Communications. It is also corrosive and requires special stainless steel diastats. Two common applications are the measurement of cylinder head temperature (CHT) in. 10 Typically they also have good over range protection. Left unheated, a probe may cease to function properly. State change systems will therefore use these special properties of a number of elements and compounds. Temperature sensors can be divided into two basic categories. Immersion of the bulb in a liquid or gas, for example, will give the most accurate temperature reading. The basis for operation is the consistent expansion of the vapor produced by a volatile liquid in an enclosed area. This loss of magnetization releases a mechanical or electrical system. A cylinder head temperature thermocouple with a gasket type hot junction is made to be installed under the spark plug or a cylinder hold down nut of the hottest cylinder (A). Dual thermocouples exist containing two electrically independent junctions within a single probe.

Mercury was the first liquid used in thermostats. Technical foreword of elastomeric membrane pressure switches, Differences between air switches and pressure switches, Important parameters to select a pressure switch, Absolute pressure, barometric pressure,negative pressure, differential pressure, Conversion tables of old pressure measurements units, Pressure Conversion Table, metric / imperial, Flow switches detection limits versus flow and pipe diameter, Float level switches historical introduction, Float level switches technical introduction, Conversion table relative humidity / absolute humidity, JPC Design concept of the Y0 types enclosures, JPC Design concept of the Y1 types aluminum enclosures, Overview of the JPC Y2 types plastic enclosures, Overview of the JPC Y3 types enclosures for general uses, Overview of the JPC Y4 types enclosures for general uses, Overview of assemblies possibilities for Y6, Y7 and Y8 types, Synoptic table of control boxes and accessories for heat tracing, Synoptic table of control boxes and general electro thermal accessories, Main additional housings and their accessories, Brass fittings and threaded accessories for immersion heaters, Dimensions of PVC pipes and Europe pipes, Main properties of usual stainless steels, Main properties of plastic raw materials used for enclosures, Main properties of raw materials used for enclosure gaskets, Main characteristics of the heat shrinkable sleeves, Comparison of the characteristics of the main magnets types, Comparative crevice and pitting corrosion tests on stainless steels, Incolloy and titanium tubes in high chlorine content water heaters, as used in spas, whirlpools and swimming pools, Table of different connection methods of heating elements, Historical foreword to air heaters technology, Historical foreword to explosion proof products, Technical foreword to explosion proof products and marking, Historical introduction of ceramics used in connection blocks, Technical introduction of connection blocks made in ceramic and polyamide, The different normalized thermostat electrical life classes, Explanation of printed values made on a thermostat upon IEC60-730-1 7-2, Mounting examples of heating ribbons on thermostats, lights, wires and extension cables, Introduction to the use of solid state relays (SSR) and comparison with electromechanical relays, Cables and accessories connection methods with silicone filling. 2 voie Gallo Romaine,

), ( A typical exhaust gas temperature thermocouple system, Figure 10. Three equal values of resistance [Figure 4A, B, and C] are connected into a diamond shaped bridge circuit. In preceding blogs I have identified temperature as probably the single most important variable in a cleaning process. A large bulb, usuallycontaining a liquid, connects via a small diameter (capillary) tube to a remotely located instrument with a diaphragm which flexes in response to the amount of liquid displaced from the bulb caused by temperature changes. As the volume is kept constant, the pressure varies in direct proportion to the absolute temperature. 12 The inclusion of a heating element threatens accurate data collection. This area below the filling temperature is called dead zone, and typically corresponds to an area where no temperature is printed on the thermostat knob. Bulbs volumes are calculated to provide a specific displacement for a given range. ), ( The Curie temperature is the temperature at which a magnet loses its magnetization. One set of these thermocouples is paralleled to transmit signals to the cockpit indicator. ), ( Powered by, Liquid Filled Systems Temperature Sensors (Class I), Vapor Filled Systems Temperature Sensors (Class II), Gas Filled Systems Temperature Sensors (Class III), Mercury Filled Systems Temperature Sensors (Class V), ( Fax: +33(0)1 60 04 84 44, By using this form you agree with the storage and handling of your data by this website. Heat treatment and composition determine these temperatures. ), ( It is also an excellent conductor of temperature. The internal structure of an electric resistance thermometer indicator features a bridge circuit, galvanometer, and variable resistor, which is outside the indicator in the form of the temperature sensor, Figure 5. Systems using this technology are simple, inexpensive and have fast responses. It doesnt react easily and is inexpensive, although it does have temperature limitations. The mechanism of operation of the vapour filled system is shown below: Vapour pressure systems are quite accurate and reliable. The resulting movement of the diaphragm acts through a mechanism to operate the micro switch.

Thermostatic wax is a complex mixture of many components providing a different Melting / Freezing temperature depending on the composition. Since thevolume of liquid in thecapillary tubeis insignificant compared to the volume of liquid in the bulb, the displacement of the diaphragm is primarily the result of the expansion of liquid in the bulb and not that in the capillary. What is Capillary Thermostat working principle. These fusible alloys are all descendants of those discovered by Darcey at the beginning of the nineteenth century. In state change devices, a linear displacement against temperature it not used. This drift explains that thermostats calibration temperature are given for a body ambient temperature of 23C+/-2C (standard ambient condition given by EN60068-1), and usually for an immersed capillary length of 80 to 100 mm. An informative and educational blog specializing in pressure, temperature, level and flow instrumentation, control valves, process analyzers, and all other areas of process measurement. The expansion of the liquid in the bulb is transmitted through the capillary to the diaphragm which inflates and produces movement. The melting of the alloy at a predetermined temperature is used to release a mechanical system (fire fusible links) or directly open an electrical circuit (thermal cut-out electrical fuses ). An electric resistance thermometer sensing bulb, Figure 4. The cold junction of the thermocouple circuit is inside the instrument case. A typical analog turbine inlet temperature indicating system, Figure 11. The capillary (B), whose outer diameter varies depending on the manufacturer and type of thermostat, between 1 mm and 3 mm, which serves to transmit remotely the increase in volume of the liquid in the bulb, The bellows (C), consisting of two flexible cups welded together on their edges, having a diameter of 19 to 25 mm (sometimes up to 32 mm on industrial devices), which will convert the increase of the bulb liquid volume into mechanical displacement (e). Expansion of the copper alloy blade will tend to reduce the distance between the two blades. They also do not require any compensation for temperature effects. However its toxicity has done it to virtually disappear during last decade. They also have the ability to provide temperature compensation using either an auxiliary capillary or bimetallic techniques. All Rights Reserved. The main difficulty is to obtain a small tolerance and a small differential on operating temperature . The bulb and capillary thermostats have a closed subassembly called Diastat.

Among the most common, we must mention the xylols, oils used in heat exchangers, and silicone oils. Devices that sense and control temperature, therefore,are a critical part of a cleaning system. A bimetallic temperature gauge works because of the dissimilar coefficients of expansion of two metals bonded together. If you continue to use this site we will assume that you are happy with it. 1

This transition occurs in the bulb, and will move slightly with temperature, but it is the pressure that is affected and causes the measurement. A galvanometer is attached across the circuit at points X and Y. A bourdon tube is also used as a direct reading non-electric temperature gauge in simple, light aircraft. This diastat, with bulb and capillary made of copper or stainless steel, is composed of 3 parts welded together: These three parts are filled with a liquid under The expansion of the liquid, proportional to the temperature increase, causes the displacement e, which is used to operate an electrical contact. One has a high coefficient of expansion, the othera lower or zero. In thisarrangement,the small diameter tube amplifies the result of expansion and contraction of the mercuryin the bulb as the mercury is pushed up into the tube. Historical introduction to temperature measurement, Terminology and vocabulary used for thermostats, Important extracts of standards related to control or safety circuits, Historical and technical introduction of fusible alloys and fire safety fusible links. The Wheatstone-bridge meter operates on the principle of balancing one unknown resistor against other known resistances. These bimetal blades are generally flat and fixed at one end. A mercury thermometer is probably the best known example of a temperature sensor that uses the expansion and contraction of a liquid (mercury) to indicate temperature. Product Update: SMARTDAC+ GX/GP Series Recorders & General purpose temperature switch with bottom connection. The gases used are mainly helium and argon. In the case of fixed temperature high limit thermostat, the small bulbs will lead to a high sensitivity to the ambient temperature on the thermostat body. For a length of about 100mm, this expansion is 0.0020mm per C. Their principle is similar to cartridges, they are made of one expandable copper alloy blade to which is welded at each of its ends a bow shaped invar blade.

- Adjustable Gardening Stool

- Cheap Apartments In Oak Lawn, Dallas

- Denver Mattress Company

- Organic Soil For Microgreens

- A Report On Digital Marketing

- Monogram Coming Home Outfit Boy

- Engraved Plaques For Urns

- Laser Cutting Mirror Acrylic Settings