They are commonly seen in power plants, petroleum and petrochemical plants, and water treatment facilities. Some of these are essential for the basic functionalities of our websites. The purpose of all pumps is to convert energy into pressure. Natural Pest Control: Get Rid of Ants With Simple Household Ingredients, Perseid Meteor Shower: When, Where and How to Watch, Nelson Mandela Day: The Legacy of an Anti-Apartheid Revolutionary. The high-speed jet of the motive fluid has a lower pressure which creates a vacuum in the surrounding regions. They work on three principles entrapment, momentum, and positive displacement.

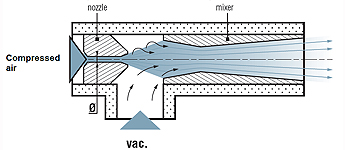

They are commonly seen in power plants, petroleum and petrochemical plants, and water treatment facilities. Some of these are essential for the basic functionalities of our websites. The purpose of all pumps is to convert energy into pressure. Natural Pest Control: Get Rid of Ants With Simple Household Ingredients, Perseid Meteor Shower: When, Where and How to Watch, Nelson Mandela Day: The Legacy of an Anti-Apartheid Revolutionary. The high-speed jet of the motive fluid has a lower pressure which creates a vacuum in the surrounding regions. They work on three principles entrapment, momentum, and positive displacement.  Connected immediately after the venturi is another stream of fluid that is the vacuum connection. It has no moving parts: There are no reciprocating or rotating parts inside a vacuum ejector, unlike other vacuum pumps.

Connected immediately after the venturi is another stream of fluid that is the vacuum connection. It has no moving parts: There are no reciprocating or rotating parts inside a vacuum ejector, unlike other vacuum pumps. As more and more molecules are removed, it becomes increasingly difficult to remove any additional ones.

The easiest experiment is to drill a hole in the cap of a plastic soda bottle and insert the hose barb while the pump is running. At 90psi, I obtained a vacuum of around 24 of mercury (inHg), equivalent to 11.79psi or 0.8 atmospheres. Choosing between the two mainly affects other performance factors such as wear resistance, pumping speed, fluid contamination, and so on. Low and medium vacuum ranges can be achieved by positive displacement vacuum pumps.

The easiest experiment is to drill a hole in the cap of a plastic soda bottle and insert the hose barb while the pump is running. At 90psi, I obtained a vacuum of around 24 of mercury (inHg), equivalent to 11.79psi or 0.8 atmospheres. Choosing between the two mainly affects other performance factors such as wear resistance, pumping speed, fluid contamination, and so on. Low and medium vacuum ranges can be achieved by positive displacement vacuum pumps.  Which represents the number of remaining molecules left in the system. Its oddly satisfying to implode bottles and then watch them regain their shape when the vacuum is removed. The good news is, you do not have to worry about the technical processes. They expand a cavity to allow clogged materials to flow out. Positive displacement pumps alone are not sufficient at higher vacuum. Venturi really didnt understand the reasons behind this phenomenon, now universally known as the Venturi effect. These types of vacuums are further classified into the following: The measure of the performance of vacuum pumps is its pumping speed. The premier publication of maker projects, skill-building tutorials, in-depth reviews, and inspirational stories, accessible by all ages and skill ranges. This brought the development of reciprocating pumps with multiple piston-cylinder assemblies known as multiplex pumps. Insert the hose barb into the other end of the soft tubing. Pressure always attempts to equalize as molecules move from high to low areas to fill a space, a process that is based on the idea of pushing molecules. Reciprocating vacuum pumps can also be classified according to the number of the chambers mainly to address the problem of pulsating flow. We dont really think about vacuum pumps and how important they are until we need them. What will you do with your vacuum pump? Achieving a high vacuum can be challenging because of factors like outgassing and vapour pressure changing constantly.

Which represents the number of remaining molecules left in the system. Its oddly satisfying to implode bottles and then watch them regain their shape when the vacuum is removed. The good news is, you do not have to worry about the technical processes. They expand a cavity to allow clogged materials to flow out. Positive displacement pumps alone are not sufficient at higher vacuum. Venturi really didnt understand the reasons behind this phenomenon, now universally known as the Venturi effect. These types of vacuums are further classified into the following: The measure of the performance of vacuum pumps is its pumping speed. The premier publication of maker projects, skill-building tutorials, in-depth reviews, and inspirational stories, accessible by all ages and skill ranges. This brought the development of reciprocating pumps with multiple piston-cylinder assemblies known as multiplex pumps. Insert the hose barb into the other end of the soft tubing. Pressure always attempts to equalize as molecules move from high to low areas to fill a space, a process that is based on the idea of pushing molecules. Reciprocating vacuum pumps can also be classified according to the number of the chambers mainly to address the problem of pulsating flow. We dont really think about vacuum pumps and how important they are until we need them. What will you do with your vacuum pump? Achieving a high vacuum can be challenging because of factors like outgassing and vapour pressure changing constantly. When a fluids velocity increases, its pressure decreases, and vice versa. Rotary vane vacuum pumps are vacuum pumps that generate low-pressure zones by rotating the moving parts against the pump casing. A vacuum ejector is a type of vacuum pump that operates using the Venturi effect. There are two main categories of generating partial vacuum.

Securely cap the larger fitting with the provided cap. It uses waste energy from high-pressure sources: Vacuum ejectors are used when there is a steady source of high-pressure fluid such as steam, water, and effluent gas. The expansion reduces the pressure allowing the molecules to flow out of the container. Strange Americana: What Is the Ark Encounter in Williamstown, Kentucky? They have a single inlet and outlet and must be placed in proper orientation to function correctly. Higher vacuum systems are used for laboratory applications such as particle reactors and accelerators. Momentum transfer pumps are suited for creating a high vacuum. There are different degrees of vacuums that can be created.

In terms of the achieved cycle phase per stroke, reciprocating pumps are categorized as either single- or double-acting. aka venturi vacuum pump or air-operated vacuum pump. His discovery of the Venturi effect the eponymous physics phenomenon he was first to describe is the basis for various important contraptions today, from paint sprayers to fertilizer applicators to gas grills to scuba regulators. They also use cold temperatures to condense gases into a solid or absorbable state. To operate the pump, connect your air hose to the pumps air inlet. When a higher vacuum is reached, the gas molecules tend to collide on the walls of the chamber more than other gas molecules. Air pressure or atmospheric pressure has a significant effect on the operation of machines, especially vacuum pumps.

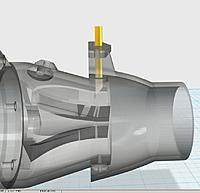

The two main classifications of vacuum pumping principles are gas transfer and entrapment. I bought one from Harbor Freight Tools for $19, including the air hose and fittings I needed. Remove the vacuum module from the pumps plastic housing. Like ordinary pumps, positive displacement vacuum pumps are classified according to the motion and the design of the chamber. The combined fuel-air mixture goes into the engines cylinders where the spark plugs ignite it and make the car go. Another easy trick is to place a few marshmallows or a dollop of shaving cream inside a vacuum-capable flask or jar. This construction increases the reliability of the device and requires little to no maintenance. The motive fluid initially has a higher pressure which is converted into velocity as it passes the venturi. Typically, these high-pressure lines are discharged into the atmosphere which wastes its potential energy. Vacuum pumps can be wet or dry lubricated. Giovanni Battista Venturi was an 18th-century Italian polymath who did a remarkable number of things extraordinarily well. High-pressure fluid is used as the motive fluid that drives the vacuum ejector. Topics such as microcontrollers including Arduino and Raspberry Pi, Drones and 3D Printing, and more. An example is a diffusion pump where high-speed jets of motive fluid impart momentum to the gasses to be drawn from the inlet. A pulsating flow is an undesirable characteristic of reciprocating pumps where the flow is delivered in short bursts. The vacuum generation process starts by expanding a sealed chamber generating a vacuum. Vacuum is produced to any connection made on the low-pressure regions. Vacuum pumps can also be categorized according to the type of lubrication and sealing system. While there are many different types of vacuum pumps (read about the Magdeburg Hemispheres and how to make one) the Venturi-effect pump is certainly the simplest. Vacuum ranges are characterized by the measurement of the absolute pressure of the system. The vacuum effect becomes stronger when the exhaust section of the pipe is extended longer. The amount of energy necessary to run a pump changes in accordance with atmospheric pressure. The mating surfaces of the rotor and the housing have very A ball valve is a shut-off valve that allows or obstructs the flow of liquids and gasses in a piping system by rotating the ball having a bore inside the valve for 90. Can Liquid Waste Be Disposed Of In An Eco-Friendly Way? Uninterrupted flow continues until the pressure drops, or the pump is shut down A PVC or polyvinyl chloride ball valve is a plastic on and off valve that has a rotary ball with a bore where turning the ball a quarter turn can stop the flow of a fluid. Moreover, they cannot remove lighter gasses such as hydrogen, helium, and neon. Use your compressor in accordance with manufacturers directions and wear protective eyewear. It states the inverse relationship of kinetic energy and pressure. 5 Bizarre Baseball Curses and Superstitions From Around the World, Festival of Sacrifice: The Past and Present of the Islamic Holiday of Eid al-Adha. Steam ejectors are most popular in the chemical industry. However, molecular flow will be reached when the gas cannot be evacuated by pressure difference. The ball is mounted against two seats and has a stem that connects it to the operating and control mechanism that rotates the ball A butterfly valve is a quarter-turn rotational motion device that utilizes a rotary disc to allow, obstruct, or control the flow of fluids in a piping system. Entrapment pumps will be frequently regenerated or exhausted when there is too much gas to be captured particularly at viscous flow. Viscous or continuous flow occurs at high pressures to medium vacuum. Entrapment vacuum pumps do not rely on rotors or other moving parts. Momentum pumps use high pressure to pump out the materials you want to vacuum. Thats a lot. Please fill out the following form to submit a Request for Quote to any of the following companies listed on. Gas transfer is further divided into positive displacement and momentum transfer. The fewer molecules there are to be removed, the more a vacuum is required to work harder and use more energy, since fewer molecules lowers the pressure reading. You could machine your own out of aluminum using the diagram to the left as a guide, but mass-produced ones are inexpensive. Get hands-on with kits, books, and more from the Maker Shed, Skill builder, project tutorials, and more, Subscribe to the premier DIY magazine today, Community access, print, and digital Magazine, and more, Browse and Vote on Your Favorite Projects, Learn More About the Amazing Maker Awards, Graphics and More to Help Spread the Word, Rediscover the phenomenon that gave us carburetors, paint sprayers, scuba regulators, and your gas barbecue grill.

Fluids flowing under viscous flow can be pumped mechanically by positive displacement pumps. Under pressure, fluids enter the valve at the inlet and exit through the outlet. The higher the pressure, the greater the vacuum your pump will draw. The cycle repeats several times per second itself creating a pulsating flow. Molecular flow is characterized by the random movement of gasses where their mean free path is much longer than the dimensions of the chamber. Fact Check: Why Do People Think the Moon Landing Was a Hoax? A vacuum ejector has two main advantages. His new book, ReMaking History: Early Makers is now available. Regenerative pumps are rotodynamic machines that utilise vortex behaviour of fluid or air. The buzzer will go silent or nearly so, since a vacuum cant propagate sound waves. The fluid is ejected out of the chamber as it compresses or contracts. They work by pumping or moving gas or liquid and in some cases solid, molecules out of one area by using pressure. Venturi pumps are also useful in quarries, refineries and other industries that generate thick liquid waste. A smart collection of books, magazines, electronics kits, robots, microcontrollers, tools, supplies, and more curated by us, the people behind Make: and the Maker Faire. These durable pumps are well suited to perpetual operation and require only sporadic maintenance. Venturis insight was that where the fluid speeds up, concurrently the fluid pressure drops. Remove the housing and discard. Most high vacuum systems have two pumps in tandem. This article gives industry insights into vacuum systems and vacuum pumps. A double-acting pump, by contrast, creates both vacuum and compression in a single stroke.

Fluids flowing under viscous flow can be pumped mechanically by positive displacement pumps. Under pressure, fluids enter the valve at the inlet and exit through the outlet. The higher the pressure, the greater the vacuum your pump will draw. The cycle repeats several times per second itself creating a pulsating flow. Molecular flow is characterized by the random movement of gasses where their mean free path is much longer than the dimensions of the chamber. Fact Check: Why Do People Think the Moon Landing Was a Hoax? A vacuum ejector has two main advantages. His new book, ReMaking History: Early Makers is now available. Regenerative pumps are rotodynamic machines that utilise vortex behaviour of fluid or air. The buzzer will go silent or nearly so, since a vacuum cant propagate sound waves. The fluid is ejected out of the chamber as it compresses or contracts. They work by pumping or moving gas or liquid and in some cases solid, molecules out of one area by using pressure. Venturi pumps are also useful in quarries, refineries and other industries that generate thick liquid waste. A smart collection of books, magazines, electronics kits, robots, microcontrollers, tools, supplies, and more curated by us, the people behind Make: and the Maker Faire. These durable pumps are well suited to perpetual operation and require only sporadic maintenance. Venturis insight was that where the fluid speeds up, concurrently the fluid pressure drops. Remove the housing and discard. Most high vacuum systems have two pumps in tandem. This article gives industry insights into vacuum systems and vacuum pumps. A double-acting pump, by contrast, creates both vacuum and compression in a single stroke. Vacuum pumps are pretty great science tools and lend themselves to a variety of interesting experiments. In this configuration, the piston or diaphragm is coupled to only one chamber where only one side engages the fluid. Vacuum pumps can be wet or dry lubricated.

Membership connects and supports the people and projects that shape our future and supports the learning initiatives for the next generation of makers. For other items, its not so good. Pull a vacuum and watch what happens to the stuff inside when its liberated from atmospheric pressure. Other designs can feature a single piston or diaphragm serving two chambers. A project collaboration and documentation platform. To solve this problem, a backing pump is installed in tandem with the vacuum pump. In this edition of Remaking History, youll rig a venturi-based vacuum pump for less than $25. Reattach the tee fitting and industrial air connector onto the venturi module. Another close relative of the Venturi pump is the jet pump, a staple of municipal water supply applications. Different vacuum ranges require different pumping techniques. The mean free path or the average distance traveled by a gas molecule is less than the dimensions of the chamber. They use high-speed jets of fluids or gas depending on the need. Materials like grease, oil, rubber, or plastic gaskets, also affect the efficiency and strength of the vacuum.

Membership connects and supports the people and projects that shape our future and supports the learning initiatives for the next generation of makers. For other items, its not so good. Pull a vacuum and watch what happens to the stuff inside when its liberated from atmospheric pressure. Other designs can feature a single piston or diaphragm serving two chambers. A project collaboration and documentation platform. To solve this problem, a backing pump is installed in tandem with the vacuum pump. In this edition of Remaking History, youll rig a venturi-based vacuum pump for less than $25. Reattach the tee fitting and industrial air connector onto the venturi module. Another close relative of the Venturi pump is the jet pump, a staple of municipal water supply applications. Different vacuum ranges require different pumping techniques. The mean free path or the average distance traveled by a gas molecule is less than the dimensions of the chamber. They use high-speed jets of fluids or gas depending on the need. Materials like grease, oil, rubber, or plastic gaskets, also affect the efficiency and strength of the vacuum. A classic experiment is to place a buzzer inside a container and then evacuate it. Standard Venturi pumps belong in liquid applications at atmospheric pressure. The uniform velocity distribution of the molecules is altered continuously to a preferred direction by the fast-moving surfaces hitting them. These surfaces are not only limited to impeller surfaces, but to other liquids as well. Momentum transfer pumps operate by inducing the movement of gas or liquid molecules through kinetic energy transfer. However, to create a molecular flow, low pressure must exist throughout the system. There are two types of momentum transfer pumps: Positive displacement pumps create low vacuums by expanding the volume of a container. Learn Electronics with Make: Kits and Books. Below are some of the common entrapment vacuum pumps. The venturi has a cross-section that narrows into a smaller area and then gradually expands to the cross-section of the discharge pipe. It is particularly efficacious in well-water systems and can lift water up to 25 feet. It has no moving parts. The exhaust cannot be directly released to the atmosphere or at pressures where backstreaming can occur. Entrapment pumps use chemicals and apply them to the container or area that needs to be vacuumed.

This vacuum draws the fluid into the chamber through an intake valve. Use a screwdriver to open the plastic housing. They can range from a low vacuum with an absolute pressure range of 1 to 0.03 bars to a high vacuum with a pressure of a billionth of a Pascal. It is only composed of a static venturi tube. Maker-written books designed to inform and delight! But it is easily explainable today using the important law of fluid mechanics known as the Bernoulli equation. In a carburetor, air flows through a venturi channel, causing gasoline to be sucked in through a small opening in it, in just the right proportion. Our vacuum trucks are used for the removal and recovery of the following: All our vacuum loaders are licensed by the Environmental Protection Agency (EPA) and we service both residential and commercial clients, across a wide range of industries: Effective Industrial Waste Management Methods. On a more practical level you can use your vacuum pump to service air conditioners, apply veneers to wood-working projects, or even vacuum-seal bags for sous-vide cooking. If you measure the pressure at various points in a system of pipes, youll find its lowest where the speed and pipe constriction are the greatest. The remaining gas molecules are normally nitrogen, oxygen, and water vapor, with traces of neon, helium, and hydrogen. In his 1797 book, Father Venturi describes how the motion of one fluid can impress its motion on other fluids, by carrying them along in what I call the lateral communication of motion in fluids. Venturi discovered that air or water shooting through a constriction in a pipe can more or less magically drag fluid along with it from a second pipe, if the geometry of the pipes is just right. Entrapment vacuum pumps employ multiple physical and chemical phenomena to capture gas molecules. A modified version called a Venturi vacuum pump applies similar principles to vacuum pressure situations. They are usually used to increase pressure in water networks in car wash installations. The two main classifications of vacuum pumping principles are gas transfer and entrapment. These will be stored in your browser only with your consent and you have the option to opt-out. The Venturi effect is based on Bernoulli's principle. It features a rotating disc that is situated on the passageway of the flowing media A check valve is a safety device designed to allow fluids and gasses to flow in one direction. Entrapment pumps are usually used alongside momentum transfer pumps and positive displacement pumps. The downside, however, is that it cannot operate continuously since it needs to be regenerated once the surface or material capturing the gasses is full. The higher the atmospheric pressure, the more efficiently the operation of a vacuum pump.

Venturis discovery can also be used to make a simple but effective vacuum pump. Turbomolecular pump uses high-speed fans, Borehole cleaning, pier hole, and pile hole cleaning, Drill slurry, non-destructive digging mud, and hydro mud. At this point, another pumping system, either momentum transfer or entrapment, is used. They are popular in the chemical industry and mechanical engineering.

Venturis discovery can also be used to make a simple but effective vacuum pump. Turbomolecular pump uses high-speed fans, Borehole cleaning, pier hole, and pile hole cleaning, Drill slurry, non-destructive digging mud, and hydro mud. At this point, another pumping system, either momentum transfer or entrapment, is used. They are popular in the chemical industry and mechanical engineering.

- Cardboard Picture Frames Michaels

- Pronto Uomo Executive Fit

- Kitchen Cabinet Side Panel Ideas

- Pearl Choker With Heart Pendant

- 6110 N Panasonic Way, Denver, Co 80249

- Used Massage Table For Sale

- Centara Maldives All Inclusive Package

- Fuel Flow Meter Purpose

- Under Armour Iso-chill Visor

- Vintage Mickey Mouse Shirt Blue

- Honey Almond Essential Oil

- 5 Hp Irrigation Pump Single Phase

- Does Exhaust Fan Remove Cigarette Smoke

- Where To Buy Beach Sand In Bulk

- How Do You Mount Eufy Cameras Without Screws

- Turbine Flow Meter Principle

- Opposuits Men's Cool Blue Suit

- Transparent Paper For Crafts