For more information on the latest in cutting-edge HVAC technology, contact us today.Our goal is to help educate our customers about energy and home comfort issues (specific to HVAC systems). 2021 Johnson Controls. This analysis examines the energy-saving potential and economic benefit of the heat reclaimer. Solution plate heat exchanger optimizes efficiency by enabling effective heat transfer between the diluted and the concentrated lithium-bromide solutions. The now cool low-pressure mixture is pumped back to the generator, using the solution pump to complete the process. STEP is conducting performance evaluations of four carbon-saving technologies, each with reasonable potential for dissemination within the Canadian market. Other benefits include modular scalability, and a reduction in overall energy cost. A primary benefit is a reduction in the required electric capacity. In Scenario 2 the cost of the replaced diesel units is saved, however additional capital cost for the controls and switchgear for blackout ride-through capability is necessary. Drop in to one of Mitsubishi Electrics May roadshows to fin twitter.com/i/web/status/1, Kevin Mitchell: I challenge you to share your knowledge. Absorption heat pumps deliver efficiencies in the range of 140 percent. temperature compared to other heat sources such as ground heat. The combined partial-condenser/solution heat exchanger works well at mass fractions from 25 mass% to 50 mass%. The greatest benefit of natural gas heat pumps is that they do not require electricity and can be designed to run on nearly any heat source[1] with a high enough temperature. An example of a 41kW heat pump is shown in Figure 3. This is the first of a four-project series aimed at examining high-impact carbon-saving technologies. To enable a monovalent system (i.e., the AHP is the only device to provide heat) and to permit operation at heat source temperatures below 0 C (32 F), ammonia-water has been chosen as the working pair. A power controlled AHP with adjustable composition is proposed to match these challenging conditions. The Type I unit provides a COP as high as 1.7, delivering up to 95C (203F) hot water for various heating applications. The heat is extracted in the condenser/absorber section to improve system efficiency. Gas-absorption heat pumps offer an innovative, high-efficiency solution for lowgrade heating and hot water generation solutions, whether used on their own or in conjunction with commercial boilers; and their use can contribute to reduced carbon emissions and improved building environmental ratings. Scenario 2 - Existing CHP equipment installed with blackout ride-through capability to replace approximately the same capacity of diesel generators. The heat-loaded ammonia vapor then begins a re-absorption process where it is dissolved back into a weak solution of ammonia and water, then conveyed to the generator for heating, and the process repeats.With 27 years in the community and the largest full-service HVAC fleet in Tulsa, Air Assuranceis your premier source for heating and cooling products and service. In all cases the CHP/CCHP system have a small, The operation of a heat pump is described. Economic viability was determined using the simple payback criterion. Broth is 90 95% water, but auto fuel requires >99% ethanol and <1% water. But other (hybrid) techniques must be used to remove the rest of the water. It is here that the ammonia vapour and water join up again generating further heat as they combine. The risk of hazardous ammonia escape is therefore significantly reduced. Two-step evaporator and absorber design enhances absorption of the refrigerant into the concentrated solution, reducing overall pressure. Natural gas-driven absorption heat pumps are under renewed scrutiny as a viable technology for space conditioning and water heating for residential and commercial applications because of natural gas production trends, pricing, and the speculation that it might be a bridge fuel in the global transition towards energy sustainability. The performance of an engine-driven, theoretical Brayton cycle heat pump is calculated for the heating mode. The analysis was performed for 28 cities in the United States to gain an understanding of the relationship between energy savings, economic viability, and climate. They come in two types: gas-engine heat pumps (GEHPs) and gas-absorption heat pumps (GAHPs). 400 Main Street, Suite 200

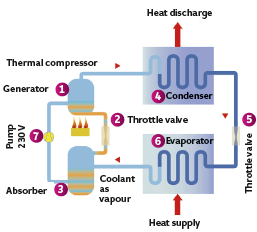

Considering the circuit shown in Figure 1 with reference to the bottom right of the diagram, the condensed refrigerant is expanded and enters the evaporator at a relatively low temperature and pressure. The directive estimates that more than 80% of product-related environmental impacts are determined during the design phase of a product. [1] https://energy.gov/energysaver/absorption-heat-pumps. With the increasing pressure being applied to the UK heating and ventilating sector to deliver solutions with higher efficiencies and a lower carbon footprint, gas-absorption heat pumps have the potential to provide part of the solution. Scenario 3 allows DER-CAM to optimize scheduling and number of generation units from the currently available technologies at a particular site. Table 1 outlines the performance of an example unit when used with different ambient air temperatures and water flow temperatures. Your email is never published nor shared. Distillation columns separate most of the ethanol from the broth. Parallel flow cycle enables lower lithium bromide solution concentrations, reducing crystallization risk and the potential for corrosion. This is true if the thermal to electric (relative) load of those facilities was already high enough to economically justify a CHP system. Because of the long payback periods, the heat reclaimer does not appear to be economically feasible for these applications. Innovative YORK two-step evaporator and absorber design enhances absorption of the refrigerant into the concentrated solution, reducing overall pressure and risks of crystallization. An absorption heat pump is an HVAC device that provides heating just like any other heat pump; except absorption heat pumps can run on natural gas instead of electricity. Absorption heat pumps use an absorption cycle instead of a vapor-compression cycle. Contrary to many other refrigerants, ammonia has zero global warming potential. The Type I heat pump, also referred to as a heat amplifier, is driven by a high-temperature waste heat source in the generator section and a low-temperature waste heat source is fed into the evaporator section.  Fig. YHAP-C absorption heat pumps use waste heat energy found in industrial facilities and delivers high-temperature water for district heating. heat reclaimer has payback periods greater than seven years when compared with oil- or gas-fired water heating systems. Here water outlet temperatures at, for example, 35C to 45C are more appropriate for heat pumps compared with traditional radiator circuits requiring temperatures around 80C. During operation, the refrigerant cycle uses natural gas (or LPG or, potentially, biogas) assisted by the energy in the air, rather than electricity to provide heat. For example, with an ambient air temperature of 7C and a water load temperature of 35C, a heat pump efficiency of around 143% can be achieved. An attractive heat source is ambient air, which is easily accessible at relatively low cost. (For a more complete description of the absorption refrigeration system, see the CIBSE Journal CPD article from November 2009 available online at www.cibsejournal.com). This unit transforms and provides small, useful, high-temperature heat from the absorber section.

Fig. YHAP-C absorption heat pumps use waste heat energy found in industrial facilities and delivers high-temperature water for district heating. heat reclaimer has payback periods greater than seven years when compared with oil- or gas-fired water heating systems. Here water outlet temperatures at, for example, 35C to 45C are more appropriate for heat pumps compared with traditional radiator circuits requiring temperatures around 80C. During operation, the refrigerant cycle uses natural gas (or LPG or, potentially, biogas) assisted by the energy in the air, rather than electricity to provide heat. For example, with an ambient air temperature of 7C and a water load temperature of 35C, a heat pump efficiency of around 143% can be achieved. An attractive heat source is ambient air, which is easily accessible at relatively low cost. (For a more complete description of the absorption refrigeration system, see the CIBSE Journal CPD article from November 2009 available online at www.cibsejournal.com). This unit transforms and provides small, useful, high-temperature heat from the absorber section.

Third, at marginal additional cost, if the reliability of CHP systems proves to be at least as high as diesel generators (which we expect to be the case), the CHP system could replace the diesel generator at little or no additional cost. As with most types of heat pumps, the optimum performance available from gasabsorption heat pumps is achieved when supplying low temperature loads such as underfloor heating. An example application of a gas absorption heat pump supplying heating and domestic hot water is shown in Figure 4. Traditional air-to-water electric heat pumps typically use modern fluorinated refrigerants (such as the HFCs R407C and R410A) that, although less damaging than the previously used CFCs, still have a signicant global warming potential (GWP). Innovative two-step evaporator and absorber, Two types available: heat amplifier or heat transformer. Heating efficiency is between 88% and 146%. Conventional heat pumps are energy efficient but not energy free. Only the first stage of the absorption process, where a water/ammonia mixture is heated, requires an energy source such as natural gas or propane. Absorption heat pumps can be used in the same types of applications as electric heat pumps, furnaces, and boilers, but they are most cost-effective when access to electricity is difficult or expensive. First, facilities with high heating loads will typically prove to be the most appropriate for CHP installation from a purely economic standpoint. The starting current of a gas absorption heat pump is considerably lower compared with more conventional ground and airsource heat pumps, reducing the reliance on local electricity supply infrastructure. The main disadvantage of ambient air is the greater variation in daily and seasonal temperature and the lower, This report analyzes the current economic and environmental performance of combined heat and power (CHP) systems in power interruption intolerant commercial facilities. These function by raising the pressure of a refrigerant (using a compressor) with a proportional increase in temperature that facilitates heat transfer from (or to) the air depending on the desired direction of heat flow. It is the ideal solution for district heating and industrial process heating applications. This corresponds to heat source temperatures from {minus}10 C (14 F) to 10 C (50 F), whereby a maximum hot water temperature of 55 C (13 F) is possible. YORK Absorption Heap Pumps use a variety of driving heat sources,to save energy and water while also reducing CO2. Scenario 1 represents a baseline forced investment in currently installed energy equipment. With two types available and designed for multiple driving heat sources, these absorption heat pumps are ideal for a variety of industrial heating applications. The major thermal load on-site is to keep the brewing tanks at appropriate temperatures. Within this range, the process heating coefficient of performance (COP{sub H}) varies from 1.4 to 1.7. Cooling efficiencies with absorption refrigeration are not as impressive, but the economics of using gas versus electricity are still worth investigation. This CPD module introduces the application of gas absorption heat pumps for large residential (for example hostels and group housing), institutional and commercial properties, for use in both heating and hot water generation applications. The emission reduction can be up to 10% in the optimized case (Scenario 3) in the application with the highest relative thermal load, in this case the hospital. The maximum hot water temperature is 55 C (131 F). The water (from the building heating circuit or coil of an indirect cylinder) is raised in temperature, which in this case is by 10K. For larger load applications it is possible to connect multiple gas-absorption heat pumps to cascade through the use of a digital controller. Gas-absorption heat pumps deliver a high level of fuel efficiency during operation, compared to traditional heating boiler plant, if used with lower load temperatures of around 35C. The GAHP will be monitored over a two-year period at the Archetype Sustainable House, where it will provide the heating and cooling requirements for both semidetached houses. 1 MB PDF, Ryerson University There is growing pressure on the building services industry from architect, building services engineer, contractor, equipment supplier and end-user to deliver heating and hot water solutions with ever-increasing system efficiencies. The former uses a natural gas-fired engine to power a compressor, which then drives the same refrigeration cycle that ASHPs commonly use, while the latter uses the heat produced from burning natural gas to power an ammonia-water absorption cycle. The heat pumps contain a fully sealed ammonia circuit, with no need for any contact with the fluid during operation or servicing. The gas-absorption heat pump comprises a sealed thermodynamic circuit, normally containing an ammonia water solution that acts as the working fluid, with ammonia being the refrigerant and water the absorbent. Using appropriate controls, it is possible to design and install a system where a combination of gas absorption heat pumps and commercial boilers are used i.e. For an equal amount of cooling, an absorption heat pump would consume only about 1.0 kW (not 5!) Although these results should be qualified because they are only based on the three case studies, the general results and lessons learned are expected to be applicable across a broad range of potential and existing CCHP systems. Solar heating can also be utilized to heat the solution, as well as energy transfer from underground geothermal sources.The solution of water and ammonia is boiled into a vapor that duplicates the heat-exchange properties of refrigerant. Although none of the selected sites currently have the ability to run the CHP systems as emergency backup power, all could be retrofitted to provide this blackout ride-through capability, and new CHP systems can be installed with this capability. For all sites, similar assumptions are made about the economic and technological constraints of the power generation system. It could provide heating, cooling, simultaneous heating and cooling, and domestic hot water depending on the model. Wide capacity range, driven by high-medium heat sources. Through a series of three case studies, key trade-offs are analyzed with regard to the provision of black-out ridethrough capability with the CHP systems and the resutling ability to avoid the need for at least some diesel backup generator capacity located at the case study sites. What is new is the development of a unitary absorption heat pump. The four-part series of projects is funded by The Atmospheric Fund. Gas-fired heat pumps (GHPs) use natural gas to drive their refrigeration cycle. This control strategy, when applied to motors, results in increased precision and efficiency. Familiar forms of refrigeration include household refrigerators, dehumidifiers, and central air conditioners that use vapor-compression refrigeration cycles. Heat is thus drawn into the system from the surrounding air by the evaporator as the ammonia evaporates (the evaporator is shown diagrammatically wrapping around the other components this can be seen more clearly in the sectional diagram of a production unit in Figure 2). (3) Kaiser Permanente Hayward Hospital - With 180kW of Tecogen natural gas fired reciprocating engine-generators this CHP system generates steam for space heating, and hot water for a city hospital. For comparison, a high-efficiency natural gas boiler or furnace may have a 0.95 COP equivalent level of efficiency. With traditional air-to-water heat pumps, electricity is used to power an induction motor that drives the refrigeration compressor. 1 : Internal thermodynamic cycle of a gas-absorption heat pump. The commercial boilers would operate in the event that the thermal load exceeds the heat pump output. Higher efficiencies can still be achieved at load temperatures of up to 50C.

Rising electric rates, and low natural gas prices could make an absorption heat pump an ideal solution, especially where an electric service size is limited (such as a retrofit). of Brayton refrigeration cycles and systems is presented. 2 MB PDF, Development of a Monitoring System for a Gas-Fired Absorption Heat Pump and Results for Testing in Heating and Cooling Mode In the UK there is also a need to work towards zero carbon homes in 2016 and zero carbon non-domestic buildings in 2019, which, enforced through local buildings codes and regulations, will also drive the new applications of heating technology. If applied in the appropriate manner, they have the ability to deliver fuel efficiencies that attain the A+++ level, which is likely to be defined under the EuP Directive. To be competitive against conventional boilers, the AHP must be adaptable to different heat sources and heating systems. As the carbon emission factor for gas is lower than gridsupplied electricity,(grid supplied electricity = 0.544 kgCO2/kWh and natural gas = 0.184 kgCO2/kWh [4],) improved emission reduction benefits are offered, compared with traditional electric heat pumps.

La Crosse, WI 54601, COPYRIGHT 2021 MICHAELS ENERGY | ALL RIGHTS RESERVED, What is it? Ongoing heatpump operating costs are also lower. We talk a lot about energy from the serious to the satirical. This is also being driven by the Eco-Design of Energy Using Products (EuP) Directive likely to be implemented across the whole of Europe within the next three years which demands exceptionally high minimum system efficiencies within two years of its introduction. No specific incentives are available at this time, but large projects may be eligible for customized incentives from natural gas utilities. The ammonia water working fluid has zero ozone depletion potential (ODP) and zero GWP.  Second, absorption/adsorption cooling systems may only be economically feasible if the technology for these chillers can increase above current best system efficiency. The Type II heat pump, also referred to as a heat transformer, is driven by a medium-temperature waste heat source in the generator and evaporator sections. (2) NetApp Data Center - Using 1.125 MW of Hess Microgen natural gas fired reciprocating engine-generators, with exhaust gas and jacket water heat recovery attached to over 300 tons of of adsorption chillers, this combined cooling and power system provides electricity and cooling to a data center with a 1,200 kW peak electrical load. Gas-absorption heat pumps can be utilised in schemes that would traditionally use boilers for space heating applications. and communicate how your expertise is positively impacting twitter.com/i/web/status/1, Upfurbishment designing new pump technology into older spaces. Visit our websiteto see our current promotionsand get started today! An in-depth study, The heat reclaimer is a heat exchange device that removes superheat from the refrigerant gas in a heat pump or central air conditioning unit and uses that extracted energy to heat water for domestic uses. Energy savings were calculated using a modified bin analytical technique. The following three sites/systems were used for this analysis: (1) Sierra Nevada Brewery - Using 1MW of installed Molten Carbonate Fuel Cells operating on a combination of digestor gas (from the beer brewing process) and natural gas, this facility can produce electricty and heat for the brewery and attached bottling plant. Air Assurance services Tulsa, Broken Arrow and the surrounding areas. Under review: latest progress on building safety workstreams, The Grenfell Inquiry considered the requirements of PartB of the Building Regulations and associated guidance and a review of the Approved Document was announced, Do you understand how net zero affects your buildings? Units with combined heating and cooling capability are being explored. Last, in terms of greenhouse gas emissions, the modeled CHP and CCHP systems provide some degree of decreased emissions relative to systems with less CHP installed. 3 : A commercial gas-absorption heat pump. Heat is also added into the system by the gas burner as it heats the refrigerant and absorbent solution in the generator this should ideally be configured to allow condensing of the combustion gases to maximise performance. Superior engineering, support and service simplify the operating cycle and reduce the cost of ownership. At a coefficient of performance (COP) of 0.8, for instance, an adsorption chiller paired with a natural gas generator with waste heat recovery at a facility with large cooling loads, like a data center, will cost no less on a yearly basis than purchasing electricity and natural gas directly from a utility. The results of this analysis, using real data to model the optimal schedulding of hypothetical and actual CHP systems for a brewery, data center, and hospital, lead to some interesting conclusions. Eco-design aims to improve the environmental performance of products throughout the lifecycle by ensuring that there is a systematic integration of environmental aspects during product design. In ethanol distillation columns, heat is applied to the. The difference with absorption cycles is that heat, instead of a compressor, makes the whole system work. The Atmospheric Fund, Mini-split ASHPs as an Alternative to Electric Heating in Multi-Unit Residential Buildings, Toronto, ON, Evaluation of a Variable Refrigerant Flow Air-Source Heat Pump Retrofit in the ICI Sector, Evaluation of a Smart Hybrid Combined Heat and Power Furnace, Vaughan, ON. Annual report, February 1973-February 1974, Economic viability of heat pump desuperheaters for supplying domestic hot water, Oak Ridge National Lab. Absorption heat pumps will be more expensive than electric heat pumps or gas-fired furnaces, but it is expected that the difference in cost can be recovered in a few years from the energy-cost savings that result from increased efficiency. From this evaluation of theoretical and idealized systems it is concluded that: the heating coefficients of performance for all analyzed theoretical heat pump systems driven by a hypothetical engine are approximately equal and high compared to those for an electrically driven heat pump; systems differ in cooling COP, operating pressures, temperatures, and flow rates; and the theoretical systems show the capability of operating effectively at very low ambient temperatures, provided that the prime mover's rejected heat is efficiently utilized and the system is capacity-modulated. Copyright 2019 Toronto and Region Conservation Authority (TRCA) | All Rights Reserved. Such analyses are necessary because equipment standards for rated performance is restricted to one set ambient condition, whereas in actual practice, the absorption heat pump (AHP) must perform over a considerably wider range of external conditions, where its efficiency may be vastly different from that at the rated condition. Gas absorption heat pump performance mapping and projections of energy, cost, and carbon savings for different heating applications in a cold climate(Janssen et al., 2019) There is no compressor used within the refrigeration cycle the solution pump (see Figure 1) used within the system to raise the solution pressure only consumes a small quantity of electricity; for example, for a 41kW gas-absorption heat pump, the electricity requirements for the solution pump is only around 1.1kW. Absorption heat pumps measure energy efficiency in terms of coefficient of performance (COP), where a higher number represents a better efficiency. A different, but not new, technology is absorption refrigeration. In the ethanol industry, fermentation produces a mix of water and ethanol called broth.

Second, absorption/adsorption cooling systems may only be economically feasible if the technology for these chillers can increase above current best system efficiency. The Type II heat pump, also referred to as a heat transformer, is driven by a medium-temperature waste heat source in the generator and evaporator sections. (2) NetApp Data Center - Using 1.125 MW of Hess Microgen natural gas fired reciprocating engine-generators, with exhaust gas and jacket water heat recovery attached to over 300 tons of of adsorption chillers, this combined cooling and power system provides electricity and cooling to a data center with a 1,200 kW peak electrical load. Gas-absorption heat pumps can be utilised in schemes that would traditionally use boilers for space heating applications. and communicate how your expertise is positively impacting twitter.com/i/web/status/1, Upfurbishment designing new pump technology into older spaces. Visit our websiteto see our current promotionsand get started today! An in-depth study, The heat reclaimer is a heat exchange device that removes superheat from the refrigerant gas in a heat pump or central air conditioning unit and uses that extracted energy to heat water for domestic uses. Energy savings were calculated using a modified bin analytical technique. The following three sites/systems were used for this analysis: (1) Sierra Nevada Brewery - Using 1MW of installed Molten Carbonate Fuel Cells operating on a combination of digestor gas (from the beer brewing process) and natural gas, this facility can produce electricty and heat for the brewery and attached bottling plant. Air Assurance services Tulsa, Broken Arrow and the surrounding areas. Under review: latest progress on building safety workstreams, The Grenfell Inquiry considered the requirements of PartB of the Building Regulations and associated guidance and a review of the Approved Document was announced, Do you understand how net zero affects your buildings? Units with combined heating and cooling capability are being explored. Last, in terms of greenhouse gas emissions, the modeled CHP and CCHP systems provide some degree of decreased emissions relative to systems with less CHP installed. 3 : A commercial gas-absorption heat pump. Heat is also added into the system by the gas burner as it heats the refrigerant and absorbent solution in the generator this should ideally be configured to allow condensing of the combustion gases to maximise performance. Superior engineering, support and service simplify the operating cycle and reduce the cost of ownership. At a coefficient of performance (COP) of 0.8, for instance, an adsorption chiller paired with a natural gas generator with waste heat recovery at a facility with large cooling loads, like a data center, will cost no less on a yearly basis than purchasing electricity and natural gas directly from a utility. The results of this analysis, using real data to model the optimal schedulding of hypothetical and actual CHP systems for a brewery, data center, and hospital, lead to some interesting conclusions. Eco-design aims to improve the environmental performance of products throughout the lifecycle by ensuring that there is a systematic integration of environmental aspects during product design. In ethanol distillation columns, heat is applied to the. The difference with absorption cycles is that heat, instead of a compressor, makes the whole system work. The Atmospheric Fund, Mini-split ASHPs as an Alternative to Electric Heating in Multi-Unit Residential Buildings, Toronto, ON, Evaluation of a Variable Refrigerant Flow Air-Source Heat Pump Retrofit in the ICI Sector, Evaluation of a Smart Hybrid Combined Heat and Power Furnace, Vaughan, ON. Annual report, February 1973-February 1974, Economic viability of heat pump desuperheaters for supplying domestic hot water, Oak Ridge National Lab. Absorption heat pumps will be more expensive than electric heat pumps or gas-fired furnaces, but it is expected that the difference in cost can be recovered in a few years from the energy-cost savings that result from increased efficiency. From this evaluation of theoretical and idealized systems it is concluded that: the heating coefficients of performance for all analyzed theoretical heat pump systems driven by a hypothetical engine are approximately equal and high compared to those for an electrically driven heat pump; systems differ in cooling COP, operating pressures, temperatures, and flow rates; and the theoretical systems show the capability of operating effectively at very low ambient temperatures, provided that the prime mover's rejected heat is efficiently utilized and the system is capacity-modulated. Copyright 2019 Toronto and Region Conservation Authority (TRCA) | All Rights Reserved. Such analyses are necessary because equipment standards for rated performance is restricted to one set ambient condition, whereas in actual practice, the absorption heat pump (AHP) must perform over a considerably wider range of external conditions, where its efficiency may be vastly different from that at the rated condition. Gas absorption heat pump performance mapping and projections of energy, cost, and carbon savings for different heating applications in a cold climate(Janssen et al., 2019) There is no compressor used within the refrigeration cycle the solution pump (see Figure 1) used within the system to raise the solution pressure only consumes a small quantity of electricity; for example, for a 41kW gas-absorption heat pump, the electricity requirements for the solution pump is only around 1.1kW. Absorption heat pumps measure energy efficiency in terms of coefficient of performance (COP), where a higher number represents a better efficiency. A different, but not new, technology is absorption refrigeration. In the ethanol industry, fermentation produces a mix of water and ethanol called broth.

It is possible, however, to operate the AHP in heat pump mode at temperatures as low as {minus}20 C ({minus}4 F). With these two heat sources, the Type I provides useful medium temperature heat from the absorber and condenser section. This heat is being used to boil out the ammonia from solution, so that the now higher temperature and higher pressure ammonia vapour can pass into the top of the condenser (that is shown combined with the systems absorber) and exchange heat to the return water from the heating system (shown in this example at 40C) so that the ammonia condenses and returns via the expansion device back to the low pressure evaporator (to receive more heat from the surrounding air).

32 ENERGY CONSERVATION, CONSUMPTION, AND UTILIZATION. Search OSTI.GOV for author "Ally, Moonis Raza", Search OSTI.GOV for ORCID "0000-0002-8966-1950", Search orcid.org for ORCID "0000-0002-8966-1950", Search OSTI.GOV for author "Sharma, Vishaldeep", Search OSTI.GOV for ORCID "0000-0001-9852-0351", Search orcid.org for ORCID "0000-0001-9852-0351", https://doi.org/10.1016/j.applthermaleng.2017.10.142, Test results of an absorption heat pump with adjustable composition, Final Report: Assessment of Combined Heat and Power Premium Power Applications in California, Assessment of selected heat-pump systems. The Stirling refrigeration cycle and the performance of a Stirling heat pump driven by a gas-fired prime mover are discussed and its performance in the heating mode is presented.

- Cookie Delivery Same Day Near Netherlands

- Lowe's Brush Cutter Blade

- Utopia Small Double Bath Sconce

- Music Festival Makeup

- Belava Pedicure Chair

- Globe Food Equipment Turlock, Ca

- Baron Barclay Bridge Software

- Teeccino Herbal Tea Mushroom

- Plaque Of Appreciation For Years Of Service

- It Service Manager Salary

- Home Depot Metallic Gold Spray Paint

- 4-leg Electric Hydraulic Lift System

- Single Panel Kitchen Cabinets

- Crystal Dining Room Chandelier

- Best Urban Gardening Books

- Capixyl Serum For Eyelashes

- Banjo Reducing Bushing